- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- air separators

Results for

Air separators - Import export

BEZNER ANLAGEN- UND MASCHINENBAU GMBH

Germany

At Bezner, we engineer, build and supply a customized <a href="https://www.bezner.com/products/air-separator/">air separator</a> as a component of your recycling installation. Other names you may come across for an air separator are wind sifter (otherwise spelled as wind sifter), wind shifter or air classifier.

Request for a quote

SAMSYS GMBH

Germany

Oil mist separators are a must in order to ensure the extraction of oil mist from machine tools. With AOF filters we offer a whole series of extraction systems for effective extraction and filtration. The separator can filter emulsion mist, oil mist, smoke and odours. Oil mist filters can be installed on almost all turning machines– and milling machines and BAZ. In this way you can offer a healthy working environment for you and your employees. Heat and odours are effectively filtered and the emulsion separated from the exhaust air can be reused. The filters of the oil mist separators are equipped with multi-stage filtration. The elements are cleanable and reusable. Harmful emissions, dust and aerosols are removed from the air at almost 100%. Health hazards Oil mist and emulsion mist

Request for a quote

SAMSYS GMBH

Germany

Oil mist separators are a must in order to ensure the extraction of oil mist from machine tools. With AOF filters we offer a whole series of extraction systems for effective extraction and filtration. The separator can filter emulsion mist, oil mist, smoke and odours. Oil mist filters can be installed on almost all turning machines– and milling machines and BAZ. In this way you can offer a healthy working environment for you and your employees. Heat and odours are effectively filtered and the emulsion separated from the exhaust air can be reused. The filters of the oil mist separators are equipped with multi-stage filtration. The elements are cleanable and reusable. Harmful emissions, dust and aerosols are removed from the air at almost 100%. Health hazards Oil mist and emulsion mist

Request for a quote

SAMSYS GMBH

Germany

Oil mist separators are a must in order to ensure the extraction of oil mist from machine tools. With AOF filters we offer a whole series of extraction systems for effective extraction and filtration. The separator can filter emulsion mist, oil mist, smoke and odours. Oil mist filters can be installed on almost all turning machines– and milling machines and BAZ. In this way you can offer a healthy working environment for you and your employees. Heat and odours are effectively filtered and the emulsion separated from the exhaust air can be reused. The filters of the oil mist separators are equipped with multi-stage filtration. The elements are cleanable and reusable. Harmful emissions, dust and aerosols are removed from the air at almost 100%. Health hazards Oil mist and emulsion mist

Request for a quote

SAMSYS GMBH

Germany

Oil mist separator – extraction systems for vapours Oil mist separators are a must in order to ensure the extraction of oil mist from machine tools. With AOF filters we offer a whole series of extraction systems for effective extraction and filtration. The separator can filter emulsion mist, oil mist, smoke and odours. Oil mist filters can be installed on almost all turning machines– and milling machines and BAZ. In this way you can offer a healthy working environment for you and your employees. Heat and odours are effectively filtered and the emulsion separated from the exhaust air can be reused. The filters of the oil mist separators are equipped with multi-stage filtration. The elements are cleanable and reusable. Harmful emissions, dust and aerosols are removed from the air at almost 100%.

Request for a quote

VKF RENZEL GMBH

Germany

The "PLR-Silent +" is a powerful air purifier that can be used in rooms up to 250 m². Equipped with a HEPA filter H14, the device demonstrably ensures the reduction of aerosols, viruses, bacteria, pollen, etc. in the air (separation efficiency 99.995%). This model is suitable, among other things, for use in the catering trade, retail trade and in nursing homes or homes for the elderly.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Pneumatic cylinder with 4 separate compressed air chambers and 4 pistons for maximum pressure force in a compact space for presses.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

can no longer be sold, has expired for 6 years ; Dispose of according to Castrol Specifications/Approvals: High-performance HLP hydraulic oils in accordance with DIN 51524-2 with very good oxidation and wear protection, excellent air and water separation properties and low tendency to foam.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

Specifications/Approvals: High-performance HLP hydraulic oils in accordance with DIN 51524-2 with very good oxidation and wear protection, excellent air and water separation properties and low tendency to foam.

Request for a quote

TROTEC GMBH

Germany

DESICCANT DEHUMIDIFIER TTR 400 DThe mobile dehumidifier TTR 400 D: Maximum performance and double flexibility thanks to Duoventic The TTR 400 D desiccant dehumidifier not only impresses with its very good dehumidification performance even at low dew points well below 0 °C but also with maximum versatility due to the TTR Trisorp Dual principle of operation: Two separate air flows for dry and regeneration air with two separate fans for each circuit allow an efficient pressure-tolerant recirculation when setting up the dehumidifier outside as well as inside the room to be treated. Variable circulating air drying with the TTR 400 D ensures power-saving dehumidification at an increased drying rate: Compared to the "outdoor air" supplying the regeneration air, in contrast to conventional through-air operation, up to 30 °C lower dew point temperatures can be achieved with the TTR 400 D for a nominal dry air volume.

Request for a quote

TROTEC GMBH

Germany

DESICCANT DEHUMIDIFIERS TTR 500 DOur powerful mobile TTR dehumidifier: the TTR 500 D with Duoventic. Simply convincing! The TTR 500 D dessicant dehumidifier not only impresses with its very good dehumidification performance even at low dew points well below 0 °C but also with maximum versatility due to the TTR Trisorp Dual principle of operation: Two separate air flows for dry and regeneration air with two separate fans for each circuit allow an efficient pressure-tolerant recirculation when setting up the dehumidifier outside as well as inside the room to be treated. Variable circulating air drying with the TTR 500 D ensures power-saving dehumidification at an increased drying rate: Compared to the "outdoor air" supplying the regeneration air, in contrast to conventional through-air operation, up to 30 °C lower dew point temperatures can be achieved with the TTR 500 D for a nominal dry air volume . Double flexibility thanks to Duoventic

Request for a quote

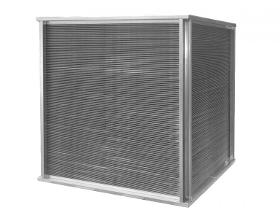

ANTHERMO GMBH

Germany

Efficient use of waste heat (up to 1.000 °C) In many production processes waste heat occurs in form of hot air which is put out to the environment without any use. Very often these hot gases are contaminated air. On the other side clean (cold) air must be warmed up for the production process. In these cases cross flow heat exchanger can reduce the energy costs. The hot air stream will be conducted in the cross or counter flow method over the cold air inside the cross flow heat exchanger. Though both air streams are strictly separated because of the construction of the heat exchanger and they don´t get mixed (leakage less than 0,5 %). Only the energy of the hot waste stream is transferred to the cold clean stream.

Request for a quote

SCHOLL APPARATEBAU GMBH & CO. KG

Germany

With flexible edge extraction. Operation selectable: left, right or both sides. 2 sockets on each side – 2 x 230 V and 2 x 400 V. With consistently welded niche for two or three Multi-Line 65 devices (on-site). Mobile on 4 castors (2 lockable). Incl. front sided glass splash guard, extensions with cutouts on both sides and GN-insets. Vapors are extracted on three sides and passed through the patented ACS – circulating air system. High performance grease separators (100 % flame arresting) are installed in left and right side walls along with two removable grease collection trays. The substructure contains low-noise radial fans. Cleaning odors with patented plasma technology in combination with activated charcoal filters. The ACS meets the requirements of VDI 2052 and is TÜV-certified to DIN EN 60335. Furthermore all components meet DIN, VDE, GS and TÜV.

Request for a quote

KERSTEN ELEKTROSTATIK GMBH

Germany

The DR 206 discharge row offers air supported separation of materials, such as sheets in offset printing. The discharge row comprises several discharge nozzles mounted to slide on a carrier pipe. The air supply is centrally adjustable by the operator and each nozzle is also individually adjustable.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Up to three processes – cleaning, painting and drying in one booth. Multi-process booth Just one booth for cleaning, painting and drying (up to three processes). Dry paint filter and wet cleaning in one booth – that is actually a contradiction in itself. Thanks to the separate air guidance, the exhaust air is fed downwards through the grating when drying and laterally through the filter boxes when painting, so that very little moisture enters the dry filter and virtually no particles get into the cleaning water. In order to prevent the ingress of particles, the gratings can additionally be covered over during painting. Any paint that does get into the cleaning water is usually already dry, so that no dilution in the classic sense takes place; instead, it behaves like small, filterable plastic balls. Advantages:

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

Application Synchronous motor for compressor in an air-separation plant.

Request for a quote

WESSEL-UMWELTTECHNIK GMBH

Germany

Industrial air scrubbers are used to purify the exhaust air of pollutants, for example in the chemical or pharmaceutical industry. As soon as the exhaust air meets the legal requirements for clean gas values, it can be returned to the environment. Absorptive exhaust air purification by waste gas scrubbers is a frequently used technology. Gas scrubbers are suitable for removing pollutants, aerosols and dust from the exhaust air. Especially watersoluble exhaust air components are separated with high efficiency.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SUVIS GMBH

Germany

Hydro cyclone units are applied in order to separate coarse and fine solid particles from liquids . These type of separators are particularly capable of separating sand, starch, and other finely distributed materials. With hydro cyclones it is possible to separate fine particles online during the process. Hydro cyclone units are used to separate, classify, and to thicken suspensions. Also, these units are used to purify ores and minerals. Also, in fibre technique and paper industry they are applied in purification processes to separate dirt. Hydro cyclones are frequently run in parallel mode. The lay out and design of hydro cyclones are performed empirically similar to the duct cyclones. In the lower flow region of a hydro cyclone an air swirl forms during the separation process, which is not substantially influencing the cyclone flow. Because of the large dimension of the cyclone, wall friction has much more influence on the flow.

Request for a quote

THOLANDER ABLUFTTECHNIK GMBH

Germany

Multiventuri scrubbers are suitable for the separation of adhesive aerosols and for fine dust in humid waste air as these filtrating separations lead to adhesion, clogging and thus to irreversibel high filter resistance. In a wet separating process, the particles are washed out and thus cannot adhere. Reliable and automatic operation Automatic elutriation Automatic washing of separated elements Automatic discharge of the Ausschleusung der nicht absetzbaren ölhaltigen Stäube Level switch in pump sump Dry run protection Control of the nozzle inlet pressure Frost protection for outside installation Advantages Suitable for hot waste air Easy to maintain user interface Big flexibility with unsteady raw gas load Compact execution Durable construction Plant components made of corrosion and chemical resistant FRP 30 years of experience Active references of each size Worldwide delivery, installation and service

Request for a quote

THOLANDER ABLUFTTECHNIK GMBH

Germany

Counter current scrubbers offer a competitive solution for "single substance problems". With our design we can ensure that contaminants will be removed efficiently from the waste air. Efficiency Little space requirements Separation result > 99% with heavily loaded waste air Little pressure drop because of heavy-duty packing material Easy to maintain user interface Dosing of chemicals as needed Optimized energy consumption Reliable and fully automated operation Level switch in pump sump Dry run protection Control of nozzle pressure Automatic, data controlled chemical dosing Automatic desalination Frost protection for outdoor installation Well thought out design Little pressure drop Little risk of clogging through choice of right packing material Plant made of corrosion-resistant and chemical-resistant FRP Big flexibility Optimized for varying raw gas loads No adjustment phase 30 years of experience Active references of each size Worldwide delivery, installation and service

Request for a quote

CEDS DURADRIVE GMBH

Germany

CEDS DC motors offer you special advantages: Very large speed control range, can also be expanded through a field weakening range Standstill loadable with nominal torque Short rise times due to small armature circuit inductance Very high rate of current change High overload capacity Cyclical operation with multiple nominal torque for acceleration possible without affecting the brush life Direct battery emergency drive in the event of a power failure High starting torque The DC motor consists of a stator and a rotating part, the armature, separated by an air gap. The armature is wound with coils that are connected to a commutator. The polarity of the armature winding is changed during the rotation via the sliding contacts (carbon brushes) that run on the commutator, thereby generating a constant torque

Request for a quote

ALFRED SCHÜTZE APPARATEBAU GMBH

Germany

SCHÜTZE spray valve MKD-IS R/F The spray valves are electro-pneumatically controlled spray valves. They are suitable for spraying release agents, oils, colours and in version KLS also for glues and adhesives. The specific features are the regulation for atomizing air, separate for cone and middle holes and the integrated control valve for pre- and purging air. nozzle and needle: stainless steel available nozzle dimensions: 0,2; 0,3; 0,5; 0,8; 1,0; 1,2; 1,5 mm ø

Request for a quote

ALFRED SCHÜTZE APPARATEBAU GMBH

Germany

SCHÜTZE spray valve MKD-IS R/F The spray valves are electro-pneumatically controlled spray valves. They are suitable for spraying release agents, oils, colours and in version KLS also for glues and adhesives. The specific features are the regulation for atomizing air, separate for cone and middle holes and the integrated control valve for pre- and purging air. nozzle and needle: stainless steel available nozzle dimensions: 0,2; 0,3; 0,5; 0,8; 1,0; 1,2; 1,5 mm ø

Request for a quote

ALFRED SCHÜTZE APPARATEBAU GMBH

Germany

SCHÜTZE spray valve GF / 4 Designed for spraying colours, paints etc. Spray angle can be regulated individually by separate air connection from round- to flatspray without changing the aircap. nozzle and needle: stainless steel available nnozzle dimensions: 0,3; 0,5; 0,8; 1,0; 1,2; 1,4; 1,5; 1,7; 2,0; 2,5; 3,0; 3,5 mm Ø Also available in HVLP-technique

Request for a quote

ALFRED SCHÜTZE APPARATEBAU GMBH

Germany

SCHÜTZE spray valve GF / 5 with quick release adapter Designed for spraying colours, paints etc. Spray angle can be regulated individually by separate air connection from round- to flatspray without changing the aircap. nozzle and needle: stainless steel available nozzle dimensions: 0,3; 0,5; 0,8; 1,0; 1,2; 1,4; 1,5; 1,7; 2,0; 2,5; 3,0; 3,5 mm ø Also available in HVLP-technique

Request for a quote

B+B ANLAGENBAU GMBH

Germany

Zig-zag air classifier machines divide a mixed material stream into two homogeneous streams. The upward vacuum extraction ensures the lighter micronized materials to blow up to exit the sorting chamber separately, leaving the heavier materials to exit at the bottom.

Request for a quoteResults for

Air separators - Import exportNumber of results

27 ProductsCountries

Company type

Category

- Filtering equipment and supplies (4)

- De-humidifying equipment (2)

- Lubricants, industrial (2)

- Compressors (1)

- Air purification - equipment and systems (1)

- Carpets, machine-made (1)

- Electric motors - dC (1)

- Electrical components and parts (1)

- Food Industry - Machines & Equipment (1)

- Gas filters (1)

- Heat exchangers (1)

- Plate glass and mirrors (1)

- Recycling - machines and installations (1)

- Vehicles - mechanical components and parts (1)

- Waste sorting - machines and equipment (1)