- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- air separators

Results for

Air separators - Import export

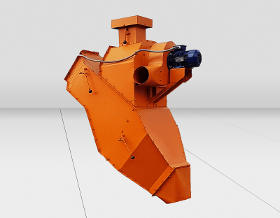

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The AS-60 air separator is used when cleaning grain to separate dust and light fractions from the grain. It can be used for different types of cereals, for example, for wheat, durum wheat, corn, rye, soy, oats, buckwheat, millet, rape, rice, as well as for sunflower, peas, chickpeas, beans, cocoa beans, etc. Cleaning grain from dust and light impurities ensures its long-term storage and helps to prevent various potential threats. Due to the unique design of the cascade type, the AS-60 air separator provides high quality cleaning of grain from dust and light impurities. Air speed and grain feed are very easy to adjust with 3 handles. This allows you to adjust the separation settings at any time depending on the properties of the grain being cleaned. Due to its simple, effective design and wide adjustment range, the AS-60 air separator has many applications. This separator can be used separately, installed in stationary grain cleaning lines or used as part of mobile grain cleaner.

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to separate the air of the product discharged under the Pneumatic Cyclonet in Pneumatic systems or under Jet Filter, Cyclone. Airlock / META

Request for a quote

VIRA ISI

Turkey

The ViraVent air separator units are installed to efficiently remove air and microbubbles from the system. In heating systems, an air separator should be installed in the flow loop where the system experiences the highest temperature (next to the heat source) and lowest pressure.

Request for a quote

BEZNER ANLAGEN- UND MASCHINENBAU GMBH

Germany

At Bezner, we engineer, build and supply a customized <a href="https://www.bezner.com/products/air-separator/">air separator</a> as a component of your recycling installation. Other names you may come across for an air separator are wind sifter (otherwise spelled as wind sifter), wind shifter or air classifier.

Request for a quote

ROBINSON CO.

Turkey

It is generally used as a dust collector, dust and air separator for the product. It is found in aspiration systems of cleaning machines. Dust removed by aspiration is separated from the air by means of a cyclone. The dust-laden carrier air is directed inside the separator thanks to the helical construction and is forced to rotate in the cyclone. Dust particles are dispersed to the environment with the effect of centrifugal forces arising due to rotation. Dust particles are carried along a helix path by means of the vortex created by the air pushed from behind. The clean air separated from the dusts goes through the suction pipe and goes to the outlet. Dust particles are directed downwards along the spiral due to the friction of the air against the wall. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

PARSMEGA MAKINA

Turkey

In pneumatic systems, it is used to separate air and product and to discharge the product inside the cyclones. The product inside the cyclones enters from the cage part of the machine and product passage is provided through the pockets on the rotor.

Request for a quote

PARSMEGA MAKINA

Turkey

The air duct is made of sheet metal construction. It is possible to make the desired air setting with air valves. Thanks to the mica glass, the cleaning process of the product can be clearly seen. The air duct is used to separate foreign substances that are lighter than the product with the help of air. It is mounted in front of the garbage separator and at the outlet of the peeler. The feeding table located at the product entrance ensures homogeneous goods flow throughout the channel. The rear curtain, which is moved throughout, allows the duct cross-section to be adjusted as desired by means of adjustment bolts. This precise adjustment of the air speed in the duct ensures that the light substances in the grain passing through the duct are separated in the desired amount.

Request for a quote

PARSMEGA MAKINA

Turkey

Pneumatic Cyclone Group is a system that moves the spilled product with air flow. The transportation process is carried out in pipes and the transported materials are sent to the Pneumatic Cyclone. Cyclones are made of sheet steel construction. It has a cylindrical-conical body and consists of an inlet and outlet pipe. It is designed to keep the air loss of the system to a minimum during the separation of air and product in the pneumatic system.

Request for a quote

ROBINSON CO.

Turkey

It is utilised to partitioned air from the item, which is released from a typhoon separator into pneumatic frameworks. It is introduced underneath the twister separators and air filters. It works with the negative weight and in addition an air seal against spillage. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories ◾ Biscuit and macaroni plants

Request for a quote

SAMSYS GMBH

Germany

Oil mist separators are a must in order to ensure the extraction of oil mist from machine tools. With AOF filters we offer a whole series of extraction systems for effective extraction and filtration. The separator can filter emulsion mist, oil mist, smoke and odours. Oil mist filters can be installed on almost all turning machines– and milling machines and BAZ. In this way you can offer a healthy working environment for you and your employees. Heat and odours are effectively filtered and the emulsion separated from the exhaust air can be reused. The filters of the oil mist separators are equipped with multi-stage filtration. The elements are cleanable and reusable. Harmful emissions, dust and aerosols are removed from the air at almost 100%. Health hazards Oil mist and emulsion mist

Request for a quote

SAMSYS GMBH

Germany

Oil mist separators are a must in order to ensure the extraction of oil mist from machine tools. With AOF filters we offer a whole series of extraction systems for effective extraction and filtration. The separator can filter emulsion mist, oil mist, smoke and odours. Oil mist filters can be installed on almost all turning machines– and milling machines and BAZ. In this way you can offer a healthy working environment for you and your employees. Heat and odours are effectively filtered and the emulsion separated from the exhaust air can be reused. The filters of the oil mist separators are equipped with multi-stage filtration. The elements are cleanable and reusable. Harmful emissions, dust and aerosols are removed from the air at almost 100%. Health hazards Oil mist and emulsion mist

Request for a quote

SAMSYS GMBH

Germany

Oil mist separator – extraction systems for vapours Oil mist separators are a must in order to ensure the extraction of oil mist from machine tools. With AOF filters we offer a whole series of extraction systems for effective extraction and filtration. The separator can filter emulsion mist, oil mist, smoke and odours. Oil mist filters can be installed on almost all turning machines– and milling machines and BAZ. In this way you can offer a healthy working environment for you and your employees. Heat and odours are effectively filtered and the emulsion separated from the exhaust air can be reused. The filters of the oil mist separators are equipped with multi-stage filtration. The elements are cleanable and reusable. Harmful emissions, dust and aerosols are removed from the air at almost 100%.

Request for a quote

SAMSYS GMBH

Germany

Oil mist separators are a must in order to ensure the extraction of oil mist from machine tools. With AOF filters we offer a whole series of extraction systems for effective extraction and filtration. The separator can filter emulsion mist, oil mist, smoke and odours. Oil mist filters can be installed on almost all turning machines– and milling machines and BAZ. In this way you can offer a healthy working environment for you and your employees. Heat and odours are effectively filtered and the emulsion separated from the exhaust air can be reused. The filters of the oil mist separators are equipped with multi-stage filtration. The elements are cleanable and reusable. Harmful emissions, dust and aerosols are removed from the air at almost 100%. Health hazards Oil mist and emulsion mist

Request for a quote

VKF RENZEL GMBH

Germany

The "PLR-Silent +" is a powerful air purifier that can be used in rooms up to 250 m². Equipped with a HEPA filter H14, the device demonstrably ensures the reduction of aerosols, viruses, bacteria, pollen, etc. in the air (separation efficiency 99.995%). This model is suitable, among other things, for use in the catering trade, retail trade and in nursing homes or homes for the elderly.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Pneumatic cylinder with 4 separate compressed air chambers and 4 pistons for maximum pressure force in a compact space for presses.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

can no longer be sold, has expired for 6 years ; Dispose of according to Castrol Specifications/Approvals: High-performance HLP hydraulic oils in accordance with DIN 51524-2 with very good oxidation and wear protection, excellent air and water separation properties and low tendency to foam.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

Specifications/Approvals: High-performance HLP hydraulic oils in accordance with DIN 51524-2 with very good oxidation and wear protection, excellent air and water separation properties and low tendency to foam.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

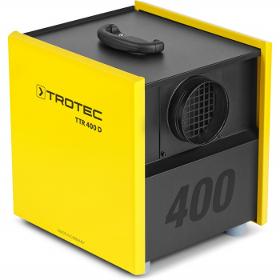

TROTEC GMBH

Germany

DESICCANT DEHUMIDIFIER TTR 400 DThe mobile dehumidifier TTR 400 D: Maximum performance and double flexibility thanks to Duoventic The TTR 400 D desiccant dehumidifier not only impresses with its very good dehumidification performance even at low dew points well below 0 °C but also with maximum versatility due to the TTR Trisorp Dual principle of operation: Two separate air flows for dry and regeneration air with two separate fans for each circuit allow an efficient pressure-tolerant recirculation when setting up the dehumidifier outside as well as inside the room to be treated. Variable circulating air drying with the TTR 400 D ensures power-saving dehumidification at an increased drying rate: Compared to the "outdoor air" supplying the regeneration air, in contrast to conventional through-air operation, up to 30 °C lower dew point temperatures can be achieved with the TTR 400 D for a nominal dry air volume.

Request for a quote

ANTHERMO GMBH

Germany

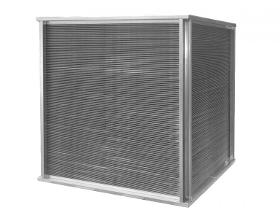

Efficient use of waste heat (up to 1.000 °C) In many production processes waste heat occurs in form of hot air which is put out to the environment without any use. Very often these hot gases are contaminated air. On the other side clean (cold) air must be warmed up for the production process. In these cases cross flow heat exchanger can reduce the energy costs. The hot air stream will be conducted in the cross or counter flow method over the cold air inside the cross flow heat exchanger. Though both air streams are strictly separated because of the construction of the heat exchanger and they don´t get mixed (leakage less than 0,5 %). Only the energy of the hot waste stream is transferred to the cold clean stream.

Request for a quote

TROTEC GMBH

Germany

DESICCANT DEHUMIDIFIERS TTR 500 DOur powerful mobile TTR dehumidifier: the TTR 500 D with Duoventic. Simply convincing! The TTR 500 D dessicant dehumidifier not only impresses with its very good dehumidification performance even at low dew points well below 0 °C but also with maximum versatility due to the TTR Trisorp Dual principle of operation: Two separate air flows for dry and regeneration air with two separate fans for each circuit allow an efficient pressure-tolerant recirculation when setting up the dehumidifier outside as well as inside the room to be treated. Variable circulating air drying with the TTR 500 D ensures power-saving dehumidification at an increased drying rate: Compared to the "outdoor air" supplying the regeneration air, in contrast to conventional through-air operation, up to 30 °C lower dew point temperatures can be achieved with the TTR 500 D for a nominal dry air volume . Double flexibility thanks to Duoventic

Request for a quote

SCHOLL APPARATEBAU GMBH & CO. KG

Germany

With flexible edge extraction. Operation selectable: left, right or both sides. 2 sockets on each side – 2 x 230 V and 2 x 400 V. With consistently welded niche for two or three Multi-Line 65 devices (on-site). Mobile on 4 castors (2 lockable). Incl. front sided glass splash guard, extensions with cutouts on both sides and GN-insets. Vapors are extracted on three sides and passed through the patented ACS – circulating air system. High performance grease separators (100 % flame arresting) are installed in left and right side walls along with two removable grease collection trays. The substructure contains low-noise radial fans. Cleaning odors with patented plasma technology in combination with activated charcoal filters. The ACS meets the requirements of VDI 2052 and is TÜV-certified to DIN EN 60335. Furthermore all components meet DIN, VDE, GS and TÜV.

Request for a quote

MIKROPOR

Turkey

Mikropor Spin-On Type Air/Oil Separators are manufactured as exchangeable elements. Because Spin-Ons do not require a compressor housing, they permit uncomplicated and quick replacement without dismantling the compressor. Spin-On Type Air/Oil Separators are available for 0,5 to 7 m³/min flow rates operating at 7 bar.

Request for a quote

MIKROPOR

Turkey

"Pleated separators increase the media surface area to reach higher capacities while maintaining the dimensions. Mikropor manufactures dozens of pleated separator designs."

Request for a quote

MIKROPOR

Turkey

The revolutionary Mikropor "3S" Separator is designed to fit the smaller separator housings without sacrificing operating performance. The "3S" separator has double to tripled capacity when compared to a conventional separator with the same dimensions. The "3S" separator has 1/2 - 1/3 of the volume of a conventional separator functioning in the same operating conditions. This increased capacity is achieved with specially designed progressive type, deep bed, coalescing media using an increased number of wraps.

Request for a quote

MIKROPOR

Turkey

Mikropor ""Conwrap"" Separators are standard wrapped style separators. Theseseparators are designed for outside to inside flow and can be used with all oil injectionRotary Vane and Rotary Screw Compressors. Conwrap separators operate between1 to 60 m³/min flow rate at 7 bar with 1 to 3 mg/m³ oil carry over.

Request for a quote

ZORLU DEGIRMEN MAKINALARI LTD. STI.

Turkey

The grain separator is used to separate small and big foreign materials (paper, straws, corn, soil etc. ) from the grain. The product is evenly distributed on the sieves by the adjustment gate at the grain intake as well as the distribution devices on the sieves. The machine consists of a vibrating body installed on a stable chassis. It is driven by two symmetrical vibration motors. The vibration level of the machine is adjusted by changing the inclination level of these motors. Rubber vibration dampeners are used to isolate the vibration. There are two layers of sieves in the grain separator. While the first layer separates the particles bigger than the grain, the second layer separates smaller particles. The grain separator has to be used with an air-channel or radial air separator. This way, the light particles are removed as well.

Request for a quote

MIKROPOR

Turkey

Our Compressed air filters are the first line of defence for any air compressor and have a significant impact on the service life of the compressor, lubricant, air/oil separators, and oil filters. We offer the highest efficiency air intake filters in the market, outperforming the competition and delivering more value to customers. With over 3000 Air/Oil Separator designs for compressors, we offer multiple options for the full range of airflow and performance requirements. Our water separators have been designed for the removal of bulk liquid water and particulate from compressed air and gases. Unique centrifugal action removes contaminants at low-pressure drop for maximum energy saving. You can download our product catalogue and brochures on the left panel in order to see our wide variety of products below.

Request for a quote

MIKROPOR

Turkey

"Mikropor manufactures a line of High Performance Compressed Air Filters, Moisture Separators in two different ranges; 50 bar range made of Aluminium. No welding, strong and reliable design. 350 bar range made of Steel. No welding and designed for reliability at very high pressure applications.Mikropor High Pressure Range Compressed Air Filters are NO-weld design. These Filters are built with ample wall thickness and as a result are extremely robust. In-house high pressure test facilities assure the performance. All inner and outer surfaces of 50 bar Aluminium design Filters are Anodised, where 350 bar Carbon Steel design Filters are epoxy electro powder coated."

Request for a quote

ZORLU DEGIRMEN MAKINALARI LTD. STI.

Turkey

The supersonic filter is used for the separation of air-dust mixtures coming from the aspiration system as well as pneumatic conveying systems. The air-dust mixture enters the machine and the dust remains on the filter bags. These filter bags are shaken out using pressurized air by the diaphragm system and the dust is collected at the bottom of the filter. For the removal of the dust collected at the bottom of the machine, a sweeper can be used as well as a conical bottom with a rotoflow.

Request for a quoteResults for

Air separators - Import exportNumber of results

82 ProductsCountries

Company type

Category

- Filtering equipment and supplies (5)

- Flour milling - machinery and equipment (5)

- Air treatment - equipment and systems (4)

- Oils, cooking - machinery and equipment (3)

- Agriculture - Machines & Equipment (2)

- Air compressors (2)

- Air conditioning equipment (2)

- Air conditioning, aeration and ventilation equipment (2)

- Compressors (2)

- Copper and copper alloys (2)

- De-humidifying equipment (2)

- Lubricants, industrial (2)

- Pneumatic conveyor equipment (2)

- Printing - flexography (2)

- Refrigerants (2)

- Air filtration equipment (1)

- Air purification - equipment and systems (1)

- Ambulance transports (1)

- Cardboard and cardboard products - processing machinery (1)

- Carpets, machine-made (1)