- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- trapezoid screws

Results for

Trapezoid screws - Import export

AVM AUTOMATION

France

Table for manual using or outside motorization Guided on ball bushings Guide tables without transmission These tables are used for manual movement or for external drives. The end plates are tapped in the center to optionally receive a hydraulic shock absorber or stroke adjustment. On request, a position clamping is available (option /BP0* on leadscrew tables). Range of linear tables with cylinder or screw transmission These tables exist, in the same dimensions, in different versions – suitable for pneumatic cylinder Type 307 – with trapezoidal screw for electric drive Type 308 – with ball screw for electric drive Type 308 – with trapezoidal screw for manual drive Type 309

Request for a quote

AVM AUTOMATION

France

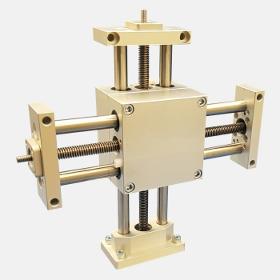

Positioning table for electric motor Guided by 2 rods on ball bushings (bronze bearings on request) Motor adaptation for linear table These leadscrew tables are delivered without motor, but the adaptation of your motor can be done by us. Some adaptations are standard, especially for standard motors (NEMA17 or NEMA23), if the dimensions of your motor are not listed, contact us to check the feasibility of your motor adaptation from our rough parts. Trapezoidal screw tables for motor The trapezoidal screw is irreversible and the axial precision of these tables is <0.15 mm (in practice 0.02 to 0.10 mm). The maxi stroke is 750 mm, and any intermediate stroke can be produced. For a XY cross table, the tables are mounted on each other directly by the body with option 308922* (smooth holes are made in the body of a table). For more precise positioning applications, these tables are available with ballscrew.

Request for a quote

AVM AUTOMATION

France

Manual table with double carriage with reversed step (the 2 carriages move away or get closer) Driving by leadscrew Guided by 2 rods Interest of table with reversed step The two carriages move away or get closer symmetrically during the rotation of the trapezoidal screw thanks to right and lefthand thread, this allows for example to adjust the spacing of the outer guides of a conveyor according to the type of product transported. Precision and robustness of right and lefthand thread table The guidance is provided by 2 rods on 4 calibrated bronze bearings (reduced play) or 4 ball bushings for guidance without clearance. The guide length of long body tables (309N/P) allows to accept large loads and torques. The axial positioning accuracy of these tables is <0.15 mm (in practice 0.02 to 0.10 mm). But the blocking in position is done on the carriage, by pressure on a guide rod, so as to remove the axial play of the nut of the trapezoidal screw after blocking

Request for a quote

AVM AUTOMATION

France

Positioning table for electric motor Guided by 2 rods on ball bushings Motor adaptation on linear table These ballscrew tables are delivered without motor, but the adaptation of your motor can be done by us. Some adaptations are standard, especially for standard motors (NEMA17 or NEMA23), if the dimensions of your motor are not listed, contact us to check the feasibility of your motor adaptation from our rough parts. Tables with ballscrew for motor The ballscrew is reversible and the axial precision of these tables is <0.07 mm. The maxi stroke is 400 mm, and any intermediate stroke can be produced. For a XY cross table, the tables are mounted on each other directly by the body with option 308922* (smooth holes are made in the body of a table). For less precise positioning applications, these tables are available with trapezoidal screw.

Request for a quote

AVM AUTOMATION

France

Lifting table for electric motor Fixing with its reinforced end for vertical using Drived by ballscrew or leadscrew Guided by 2 rods on ball bushings (or plain bearings in leadscrew version) Motor adaptation for lifting table These lifting tables are delivered without motor, but the adaptation of your motor can be done by us. Some adaptations are standard, especially for standard motors (NEMA17 or NEMA23), if the dimensions of your motor are not listed, contact us to check the feasibility of your motor adaptation from our rough parts. Presentation of the lifting tables to be motorized The trapezoidal screw version is irreversible and the axial precision is <0.15 mm (in practice 0,02 to 0,10 mm). The ballscrew version is reversible and the axial accuracy is <0.07 mm. The maxi stroke is 300 mm, and any intermediate stroke can be produced. Assembly of tables in XZ, YZ or XYZ systems For a crossed table XZ

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AVM AUTOMATION

France

Manual positioning table drived by lead screw Guided by 2 rods on bronze bearings or ball bushings Precision manual tables The guidance is ensured by 2 rods on 4 calibrated bronze bearings (reduced play) or 4 ball bushings for guidance without play. The guide length of long body tables (309L/M) allows to accept large loads and torques. The axial positioning accuracy of these tables is <0.15 mm (in practice 0.02 to 0.10 mm). But the blocking in position is done on the carriage, by pressure on a guide rod, so as to remove the axial play of the nut of the trapezoidal screw after blocking. Manual crossed tables XY or YZ For the creation of XY crossed table, the tables are mounted one on the other directly by the body (long body version only) with the option 308922 * making smooth holes in the body of a table. To combine 2 tables in YZ, it is preferable to use a lifting table for the Z axis, mounted by its end on the body of the horizontal table.

Request for a quote

AVM AUTOMATION

France

Economical manual positioning table drived by leadscrew. Actuated by grip knob. Guided by 2 rods on bronze bearings. Using of economical manual tables Acting is done by a grip knob supplied with the table. Maxi stroke is 100 mm for size 0, and 200 mm for sizes 1 and 2. Any nonstandard intermediate stroke can be produced. The locking in position is done on the trapezoidal screw, either in position B1 (above the front plate) or in position B2 (at the end of the end plate) depending on the access and the space available. The position is visualized by a mechanical indicator or by ruler on the base plate. The fixing on the frame is done by the 2 end plates (laminated holes) or by the end plate in « Z axis » version for vertical applications. The positioning accuracy of economical manual tables The axial positioning accuracy of these tables is <0.20 mm (in practice 0.05 to 0.15 mm), because the axial play is largely eliminated after locking in position

Request for a quoteResults for

Trapezoid screws - Import exportNumber of results

8 ProductsCountries

Company type

Category