- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pressing materials

Results for

Pressing materials - Import export

MICROCERTEC

France

Silicon nitride is one of the hardest ceramics but also one of the most resistant. Si3N4 is mainly used in severe environments which combine extreme temperatures with abrasive and/or corrosive medium. Silicon nitride can be of different grades : sintered, hot pressed or reaction bonded. Selection of materials Microcertec offers two high-purity Si3N4 grades that are particularly suited for hostile environments : sintered silicon nitride hot pressed silicon nitride Both Si3N4 materials are mainly designed to be used in thermal-mechanical or corrosion-resistance applications because they show an outstanding behaviour to resist to wear, thermal shocks and corrosion (liquids and gases). Moreover, these pure Si3N4 grades offer a low thermal expansion. Properties Sintered silicon nitride and HP Si3N4 have the following properties : low density excellent thermal shock resistance excellent wear resistance excellent corrosion resistance (liquids and gas) low coefficient of thermal...

Request for a quote

DENTALEF

France

Onlay, a prosthetic part intended to restore a loss of dental substance, is mainly indicated in restorations of posterior teeth with medium to large cavities. There are 3 types of aesthetic materials: composites, pressed E-max and machined zirconia. On the aesthetic level: E-max, highly translucent ceramic vitro confers a better aesthetic rendering The composite onlay will allow you access to an aesthetic result close to natural shades At the mechanical level: The E-max is easy to touch up and polish in the mouth onlay zirconia will be the most difficult to touch up due to their hardness At the level of biocompatibility: excellent biocompatibility and high corrosion resistance

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

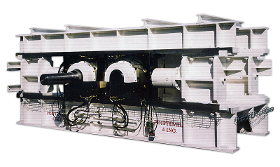

The Cylinder mill, commonly known as the Roller Press works by crushing the material between two cylinders kept under pressure by a hydraulic system (2 to 10 T/linear cm). This mill uses a patented process of pulsating pressure that reduces the level of vibration and contributes in reducing energy requirements and prolonging the service life of wearing parts. It is able to treat high production capacities (up to 500 T/h) and produce fine particle sizes (10 to 1000 microns). Cylinder mills allow for energy savings of up to 30% compared with mills that use traditional crushing methods. The cylinders are equipped with an antiabrasive coating which combined with their slow processing speed provide the grinding solution with the longest service life on the market.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Pressing materials - Import exportNumber of results

3 ProductsCountries

Company type