- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- coupling screws

Results for

Coupling screws - Import export

NORELEM FRANCE

France

Steel C35Pb. Gunmetal Rg7. Plastic PA6.6 with MoS2). ISO trapezoidal thread based on DIN 103. Steel nuts for adjustments during manual operation and as fastening nuts. Not advised for use with motorised drives due to the steelsteel material combination. Gunmetal nuts for motion drives with low and medium speed. By insufficient lubrication, gunmetal trapezoidal thread nuts on steel spindles have good dryrunning properties. Plastic nuts for lownoise motion drives. Good dryrunning properties. Tolerance class 7H.

Request for a quote

NORELEM FRANCE

France

Universal joints with plain bearing can be swivelled by 45°. Max. transferable torque (Nm) at 150 rpm, operation angle α < 5°. * Bore depth is less than by DIN 808.

Request for a quote

NORELEM FRANCE

France

Keyless locking coupling with low mass and moment of inertia. Easy to connect and release – no jamming on the shaft. Perfect for zero backlash connections. Excellent concentricity and running. Suitable for keyed and keyless shafts. for shaft diameters from 5 to 35 mm for high torques minimum axial offset when mounting selfcentring Assembly Shaft and hub must be free of oil, grease and dirt. Do not lubricate keyless locking coupling. Insert keyless locking coupling in the hub seat and slide onto shaft. Tighten nut by hand and use a torque wrench to tighten to the defined tightening torque. Tolerances Shaft diameter and hub hole Form A ±0.04 mm. Form B ±0.08 mm. Surface quality Rz ≤ 16 µm.

Request for a quote

NORELEM FRANCE

France

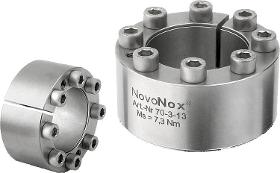

Coupling stainless steel 1.4057. Screws stainless steel 1.4301. For applications that require a small construction volume and low surface pressure. The keyless locking coupling can be fully recessed in a hub connection. for shaft diameters 6 20 mm suitable for hubs with low wall thickness minimum axial offset possible selfcentring Assembly Lightly oil keyless locking coupling on the tapered faces and contact points of the shaft and hub. Do not use MoS2 or grease. Insert keyless locking coupling in the hub seat and slide onto shaft. Tighten screws crosswise in several increments to the defined tightening torque. Dismantling Remove all screws and screw into the extraction threads of the front flange. Tighten screws crosswise in several steps until the keyless locking coupling loosens. Tolerances Shaft Recommended tolerance h8. Surface quality Rz ≤ 16 µm. Hub Recommended tolerance H8. Surface quality Rz ≤ 16 µm.

Request for a quote

NORELEM FRANCE

France

Particularly compact selfcentring keyless locking coupling without axial offset. for shaft diameters from 8 to 85 mm for medium torques suitable for hubs with low wall thickness no axial offset selfcentring Assembly Lightly oil keyless locking coupling on the tapered faces and contact points of the shaft and hub. Do not use MoS2 or grease. Insert keyless locking coupling in the hub seat and slide onto shaft. Tighten screws crosswise in several increments to the defined tightening torque. Dismantling Remove all screws and screw into the extraction threads of the front flange. Tighten screws crosswise in several steps until the keyless locking coupling loosens. Tolerances Shaft Recommended tolerance h8. Surface quality Rz ≤ 16 µm. Hub Recommended tolerance H8. Surface quality Rz ≤ 16 µm.

Request for a quote

NORELEM FRANCE

France

Shrink disc to connect a hollow hub to a shaft. They are mounted on the OD of the hub and generate pressure on the hub wall by reducing the ID with wedgeformed rings, creating a press fit between the hub and shaft. They are suitable for static, dynamic and shock loads. for extremely high torques no axial shaft/hub offset when assembling selfcentring The version 23380014072 has high tensile ISO 4762 screws. Assembly Remove existing transportation locks. Clean and lightly oil shaft, internal and external hub diameters. Do not use MoS2 or grease. Slide shrink disc onto hub. Then slide unit (shrink disc/hub) onto shaft and position correctly. Gently tighten clamping screws one after the other by hand. Then use a torque wrench to tighten the clamping screws crosswise in several increments to the defined tightening torque MS. 1st increment approx. 33% MS 2nd increment approx. 66% MS

Request for a quote

NORELEM FRANCE

France

Steel 1.0718. Stainless steel 1.4305. Version Steel black oxidised. Stainless steel bright. Note Rigid couplings transmit high torques without rotational play. They are used where there are no shaft displacements or alignment errors. Wearfree and maintenancefree. Screws secured to avoid vibration induced loosening. The maximum torque transmission can only be achieved through optimal installation and correct shaft dimensions. Maximum speed 4000 rpm.

Request for a quote

NORELEM FRANCE

France

Centre disc polyacetal. Hub aluminium. Note Clamping the hub with a grub screw is a costeffective alternative to the Oldhamtype couplings with radial clamping hub (23030). Short mounting times. The couplings can be mounted completely assembled or a plugin assembly is also possible. Take note of the tightening torque for the grub screw. To ease removal we recommend milling a flat on the shaft. Assembly The shaft to hub hole fit is a transition fit. The play should be min. 0.01 mm and max. 0.04 mm i.e. shaft Ø 6 f7 hub Ø 6 H8. Advantages robust plugin playfree short design On request Hub bores D1 and D2 with separate tolerance class or range.

Request for a quote

NORELEM FRANCE

France

Spider polyurethane hardness Shore 98A. Hub aluminium. Conical ring carbon steel. Note This coupling series is particularly suitable for use in high speed main spindle or drill spindle drives. Before the plugin assembly, both clamping ring hubs must be fastened to the shafts with the correct tightening torque. Lightly oil the spider to ease assembly. Assembly The shaft to hub bore fit should be a transition fit. The play should be max. 0.02 mm. i.e shaft Ø 25 k6 bore Ø 25 G6. Bores smaller than D1/D2 min. are possible, however an optimal transfer of the nominal torque is no longer guaranteed. On request Hub bores D1 and D2 with separate tolerance class or range. Drawing reference 1) elastomer spider

Request for a quote

NORELEM FRANCE

France

D1 and D2 are customer specific e.g. 230122025; D1 = 5H7, D2 = 8H7 Note Zero backlash, torsionally rigid, resiliently flexible and maintenancefree full metal coupling for transmitting angle synchronous rotary movement. The innovative slit structure makes possible a very good axial, radial and angular flexibility with low reset force. Ideal for servomotors. Assembly Recommended shaft tolerances h7.

Request for a quote

AVM AUTOMATION

France

Rods for ball bushings and plain bearings Ø10, 12, 16, 20, 25, 30 et 40 mm Guide rods with tapping at both ends (except stainless steel just 1 side) 4 matters hardened steel, chromed steel, stainless steel 304L, hardened stainless steel Several lenghts and special length on request.

Request for a quote

AVM AUTOMATION

France

Floating rod coupling for pneumatic, electric or hydraulic cylinders Zinc steel or stainless steel 304L With axial play or adjustable play Floating coupling for cylinder rod These rod couplings make it possible to connect the rod of a pneumatic cylinder (or electric) to any part to be set in motion while avoiding any stress on the rod. They are available in 2 versions . with axial play (<0.20 mm) usual pneumatic applications and for pushing applications . with adjustable play for positioning applications => The version with axial play allows a radial compensation of the axis of the cylinder rod, it’s for usual pneumatic applications => The version with adjustable play allows the axial play to beRod coupling with adjustable axial play – reduced by screwing the cylinder rod against the internal pin and then unscrewing it slightly (then lock with the cylinder rod nut against the coupling) – removed by screwing the cylinder rod against the internal part (with tightening)

Request for a quote

AVM AUTOMATION

France

U guide unit for pneumatic cylinders ISO Ø12 to Ø80 Antirotation guide on bronze bearings Protected by wipers seals Antirotation for ISO pneumatic cylinder This Light Series provides antirotation of the cylinder rod. With limited dimensions, it permits to use an ISO cylinder for shortstroke translations, while protecting the rod of the cylinder with its floating rod coupling. For environments requiring an anticorrosion version, the steel parts can be supplied in stainless steel (rods, coupling, screws), the body and the front plate are remaining in anodized aluminum (suffix /AC after the reference). For all stainless steel guides, refer to the 34*X series.

Request for a quote

AVM AUTOMATION

France

U guide unit for pneumatic cylinders ISO Ø32 to Ø80 Short guide on bronze bearings Protected by wipers seals Short guide for ISO15552 pneumatic cylinder This Classic Series provides antirotation of the cylinder rod. The guide is shorter than the H Classic series and is only available in plain bearings, so this series is recommended for low strokes and moderate loads. Anticorroding Uguide For environments requiring an anticorrosion version, the steel parts can be supplied in stainless steel (rods, coupling, screws), the body and the front plate are remaining in anodized aluminum (suffix /AC after the reference). For all stainless steel guides, refer to the 34*X series. Protection kit and back stop kit on Uguide The protection kit (tube wrapping the rods at the rear of the guide), for example allows to avoid a guarding housing on a semiautomatic machine (label maker …). The back stop kit, with hydraulic shock absorber, allows

Request for a quote

AVM AUTOMATION

France

For pneumatic cylinders ISO Ø8 and Ø10 Guide on bronze bearings or ball bushings The smallest guide unit in the range It’s the smallest unit, suitable for ISO6432 Ø8 and Ø10 pneumatic cylinders, allowing an ISO cylinder to be kept for small guided cylinder applications. It has a long Ushape to remain compact and have a guide length comparable to an Hshape. For environments requiring an anticorrosion version, the steel parts can be supplied in stainless steel (rods, coupling, screws), the body and the front plate are remaining in anodized aluminum (suffix /AC after the reference). Any special stroke is possible, with a maxi stroke of 200 mm.

Request for a quote

AVM AUTOMATION

France

H guide unit for pneumatic cylinders ISO Ø25 to Ø125 Very sturdy guide on plain bearings Protected by wipers seals Guide unit with large rods This Heavy Series has bigger guide rods than the Strengthened series. The thick front plate also allows long centering of the guide rods for better resistance to torsion. Only available in plain bearing version, it’s recommended for important radial loads in static. Sturdy guide for Ø125 cylinder Adapted to the ISO6432 (Ø25) and ISO15552 (Ø32 to 125) cylinders, this range therefore also makes it possible to meet the more robust guide needs for Ø125 cylinders, the guide rods then being Ø40, on 4 plain bearings. Anticorroding heavy guide For environments requiring an anticorrosion version, the steel parts can be supplied in stainless steel (rods, coupling, screws), the body and front plate are remaining in anodized aluminum (suffix /AC after the reference). Scrapers in polyurethane can be proposed for dusty or dirty environments.

Request for a quote

AVM AUTOMATION

France

Table for pneumatic cylinders ISO Ø16 to Ø40 Guided on ball bushings Protected by wipers seals More rigid than a H guide unit These tables maintaining the same quality of guidance and rigidity throughout the stroke. For a offcentered payload in vertical, these tables allow to be more rigid than a guide unit in H. Hydraulic shock absorber on this table A hydraulic shock absorber may be placed in opposition to the pneumatic cylinder to dampen, for example, the descent and/or limit the stroke at the output of the cylinder rod. The retracting stroke can be adjusted by the floating rod coupling. Use in harsh environment For dusty environments, additional nitrile or polyurethane scrapers can be added in front of the ball bushings. An anticorrosion version can be proposed with the rods, the coupling and the screws in stainless steel (the carriage and the plates remain in anodized aluminum). It’s possible to make these tables with plain bearings (bronze or polymer) on request.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EID

France

Allows two precharged systems to be coupled when screwed together. Unions are tightened with two spanners, until the 2 seals, male and female, are broken.

Request for a quote

EID

France

Allows two precharged systems to be coupled when screwed together. Unions are tightened with two spanners, until the 2 seals, male and female, are broken.

Request for a quoteResults for

Coupling screws - Import exportNumber of results

20 ProductsCountries

Company type