- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- plastic injection molding

Results for

Plastic injection molding - Import export

NORELEM FRANCE

France

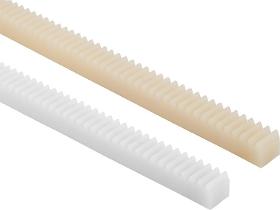

Injection moulded, straight teeth. Engagement angle 20°. Polyacetal, white. Polyketone, ivory tone. Note Polyacetal Standard material with high hardness grade and low coefficient of friction. Polyketone Material with significantly longer service life, higher power transmission and greater security against tooth breakage due to the extraordinarily high wear resistance and very good tribological properties. Can be used under water and other media. Due to the material properties, plastic gear racks are not straightened. L= nominal length 250 mm. The actual length is roughly a whole multiple of the pitch.

Request for a quote

NORELEM FRANCE

France

Injection moulded, straight teeth. Engagement angle 20°. Machined bore. Polyacetal, white. Polyketone, ivorytone. Note Polyacetal Standard material with high hardness grade and low coefficient of friction. Polyketone Material with significantly longer service life, higher power transmission and greater security against tooth breakage due to the extraordinarily high wear resistance and very good tribological properties. Can be used under water and other media. Injection moulded gear wheels may have internal manufacturerelated cavities. These may become visible during drilling or broaching. They do not impair the function. The torques specified in the tables relate exclusively to the toothing.

Request for a quote

NORELEM FRANCE

France

Injection moulded, straight teeth. Engagement angle 20°. Axis angle = 90°. Machined bores from module 1.5. Polyacetal, white. Polyketone, ivory tone. Note Polyacetal Standard material with high hardness grade and low coefficient of friction. Polyketone Material with significantly longer service life, higher power transmission and greater security against tooth breakage due to the extraordinarily high wear resistance and very good tribological properties. Can be used under water and other media. Injection moulded gear wheels may have internal manufacturerelated cavities. These may become visible during drilling or broaching. They do not impair the function. Bevel gear wheels are supplied as single components. To obtain a pair of bevel gear wheels, please order the specified mating gear as well.

Request for a quote

REP INTERNATIONAL

France

V79 : a model with innovative ergonomics : no pit for the press, no platform for the operator. This customized V79 is used for large volume bi-material injection with automatic loading and demolding.

Request for a quote

REP INTERNATIONAL

France

Machine features Clamping force 500 kN. Size of the platens 300 x 300 mm. Injection volume 125 cm³.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

REP INTERNATIONAL

France

Lean range G10 Core The G10 is the 10th generation of REP injection molding machines. With its ergonomic design and intelligent onboard solutions, the G10 generation is branded "Infinitely Smart". The G10 is available in two versions, G10 Core (Lean range) and G10 Extended (Performance range), designed to better meet the varied needs of customers. Lean range G10 Core Vertical rubber injection molding machines REP ideal for less demanding processes. The G10 Core range exists with three clamping forces 1,600 kN 3,050 kN 5,100 kN.

Request for a quote

REP INTERNATIONAL

France

Performance range G10 Extended Intelligent, elegant and efficient The G10 is the 10th generation of REP injection molding machines. With its ergonomic design and intelligent onboard solutions, the G10 generation is branded "Infinitely Smart". The G10 is available in two versions, G10 Core (Lean range) and G10 Extended (Performance range), designed to better meet the varied needs of customers. The G10 Extended is a line of presses adapted to the most demanding processes. The G10 Extended is progressively replacing the G9 generation machines and ranges from 1,600 kN (V410) to 10,200 kN (V910).

Request for a quote

REP INTERNATIONAL

France

Economic injection molding presses. A REP injection unit combined with a closing unit of a Tung Yu press. This combined technology offers openended options Separate extrusion and injection thanks to the "Y" type injection unit. 2 or 3stroke closing unit. Proportional closedloop temperature control. Optimized floor space and ergonomics thanks to its modular design.

Request for a quote

REP INTERNATIONAL

France

The Microject is a micromachine of a clamping force of 60 tons designed for the injection molding and overmolding of inserts used in small parts. Usability and flexibility. Plug and Produce! Characteristics MICROJECT LSR Maximum injection volume 3.77 (at 2000 bar) or 6.94 (at 1500 bar) or 10.37 (at 1000 bar). Clamping force 60 kN. Mould dimensions 150 x 100 mm. Overall dimensions 1.2 x 0.75 m. Simplicity and flexibility Installation in 30 minutes. Mould setting time optimally reduced. Intuitive touch screen interface.

Request for a quote

REP INTERNATIONAL

France

CFrame Injection molding machine V19. Optimized floor space and maximum accessibility. The V19 is an advanced Cframe press of 400 kN available in 2 versions, plastic or rubber injection. Its accessibility from three sides makes it ideal for the injection molding of profiles and extruded hoses.

Request for a quote

REP INTERNATIONAL

France

Type V510 Extended 3,050kN Machine features Clamping force 3,050 kN. Size of the platens 500 x 630 mm (630 x 630 mm optional). Injection volume 1,000 or 2,000 cm³. The G10 Extended range, performance for complex processes. Designed to better meet the various customer requirements with its embedded intelligent solutions.

Request for a quote

REP INTERNATIONAL

France

URP Joint venture United Rubber Machinery Strategic Alliance for Asian injection molding machine market between REP and LWB Steinl,

Request for a quote

REP INTERNATIONAL

France

Machine features Clamping force 1,950 kN. Size of the platens 450 x 450 mm. Injection volume 1,000 cm³. The H49 is designed for Automated production. Injection molding (more or less simple parts). Low floor space and height requirement. An optimized cycle time. etc

Request for a quoteResults for

Plastic injection molding - Import exportNumber of results

14 ProductsCompany type