- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machine tables

Results for

Machine tables - Import export

NORELEM FRANCE

France

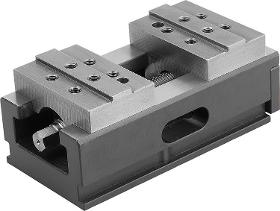

Tightening the ball-end thrust screw moves the jaw plates forwards. The workpiece is pushed against the fixed stop and simultaneously forced down onto the seating face. The seating face for the workpiece can be mounted directly on the machine table.

Request for a quote

NORELEM FRANCE

France

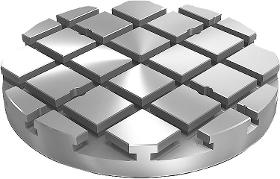

Round baseplates with T-slots are used for constructing modular fixtures. These baseplates are positioned and mounted directly on machine tables. The precise longitudinal and transverse slot spacing ensures very high repeat clamping accuracy. The aligning holes are used to align the baseplate on the machine table. Please order locating pins to locate the baseplates separately. Ring bolts with T-nuts for hoisting are supplied. Other dimensions available on request. On request: other dimensions. Drawing reference: 1) hole for DIN 912 cap screw (D4)

Request for a quote

NORELEM FRANCE

France

Grid spacing 50 ±0.02 mm. Tombstones with grid holes are used on horizontal machining centres. The alphanumerically labelled grid holes guarantee a defined assignment of clamping elements by repeat setups. The tombstones conform to machine tables for machine tools acc. to DIN 55201 and JIS 6337-1980. Please order locating pins for positioning subplates on machine tables acc. to DIN 55201 separately. Please order protection plugs to plug unused grid holes separately. Ring bolts for hoisting are supplied. Other dimensions available on request. Drawing reference: 1) grid hole 2) hole for DIN 912 cap screw (D3/D4)

Request for a quote

NORELEM FRANCE

France

Grid spacing 50 ±0.02 mm. Tombstones with grid holes are used on horizontal machining centres. The alphanumerically labelled grid holes guarantee a defined assignment of clamping elements by repeat setups. The tombstones conform to machine tables for machine tools acc. to DIN 55201 and JIS 6337-1980. Please order locating pins for positioning subplates on machine tables acc. to DIN 55201 separately. Please order protection plugs to plug unused grid holes separately. Ring bolts for hoisting are supplied. Other dimensions available on request. Drawing reference: 1) grid hole 2) hole for DIN 912 cap screw (D3/D4)

Request for a quote

NORELEM FRANCE

France

These toe clamps can be used on machine tables or adapter plates. The positive down force holds the workpiece down on the supporting surface. The square washer can adapt slightly to an angular position i.e. the workpiece does not have to be exactly parallel. The clamping washer has a smooth side for machined surfaces and a serrated side for rough faces.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NORELEM FRANCE

France

Body and jaw holder hardened and ground. Note for ordering: Supplied with hexagon crank handle. Order jaw plates separately. Note: Mechanically operated centric vice. Suitable for automation: prepared with gripper slot for handling systems. Flexible mounting: suitable for zero-point systems, mounting on machine tables or on custom systems via a baseplate. Centring precision: +/- 0.02 mm. The use of a torque wrench is recommended to achieve a controlled clamping force. Features: Clamping slide and spindle nut in one piece Slots and fastening threads for mounting attachment jaws Reversible jaws (accessories) with lateral thread for workpiece stop enables a wider clamping range Good swarf and coolant removal

Request for a quote

NORELEM FRANCE

France

The UNI lock mounting clamps can be installed in any position on machine tables, fixtures or workholding equipment (tooling plates, cubes, tombstones etc). The modular design enables the number of clamps and distance between them to be ideally adjusted to suit the clamping task. The clamps can be supplied with or without rotation lock. The high clamping forces are generated by the integrated spring package (the unit clamps when depressurised). Compressed air is applied to release the clamp. The following holding forces are possible with the UNI lock clamping bolt in conjunction with M10, M12 or M16 fastening screws: Holding force (M10) 35,000N Holding force (M12) 50,000N Holding force (M16) 75,000N Supplied with: 1x clamping module incl. 6 fastening screws. 6x screw protection caps. 2x air connection O-rings. 1x installation O-ring.

Request for a quote

NORELEM FRANCE

France

Completely mounted multi-clamping stations with integrated UNI lock Ø138 mm mounting clamps. The clamping stations are secured to the machine table directly or with clamps. Common bore patterns are pre-centred on the rear side for mounting. Clamping stations can be aligned via the 14H7 reference holes. The clamping stations are actuated via a central pneumatic connection. The high clamping forces are generated by the integrated spring package (the unit clamps in the de-pressurized state). The release process occurs pneumatically. The following retaining forces are possible with the UNI lock clamping bolt in conjunction with mounting screws M10, M12, M16: Retaining force (M10) 35,000N/module Retaining force (M12) 50,000N/module Retaining force (M16) 75,000N/module

Request for a quoteResults for

Machine tables - Import exportNumber of results

9 ProductsCompany type