- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- fluid meters

Results for

Fluid meters - Import export

POREX TECHNOLOGIES GMBH

Germany

Ensure sample purity for microfluidic diagnostic systems POREX ® microfluidic media and filters provide sample filtration and absorption, particulate capture, debubbling, venting, fluid metering, and separation for real-time, PCR and molecular diagnostics systems. Our highly specialized, pure materials and media are critical to the function of lab-on-a-chip, molecular diagnostics, and POC analysis solutions by: Minimizing interference with critical samples and assays – Certified Pure POREX® materials certified by independent test labs ensure optimal performance, accuracy and reproducibility. Making manufacturing easier – Our components can be easily inserted into your device using common manufacturing techniques including press fitting, heat staking and ultrasonic welding. Providing customized material solutions – Our proprietary material technology expertise can help find the right material solution for any microfluidic component need. Applications Sample...

Request for a quote

EGE-ELEKTRONIK SPEZIAL-SENSOREN GMBH

Germany

EGE sensors for fluid mediums with integrated measuring & amplifier are compact devices with extremely robust housing and integrated measuring and amplifier. The current flow state is displayed at the sensor using LEDs. The measurement takes place without mechanically moving parts using a thermal measuring element. Limit values are set directly at the device. These sensors are used wherever a safe, reliable and low-maintenance recording of flows is required. This includes e.g. all automation and chemical industries in the most varied areas, such as cooling circuit monitoring, monitoring the flow rate of process fluids, monitoring metering processes or also for pump protection.

Request for a quote

EGE-ELEKTRONIK SPEZIAL-SENSOREN GMBH

Germany

EGE flow sensors without integrated Amplifier permit the space-saving flow measurement on site and the comfortable setting of the limit value using separate amplifier, e.g. within a control cabinet. The measurement takes place without mechanically moving parts using a thermal measuring element. The current flow state is displayed at the amplifier using LEDs. The sensor can be exposed to high temperatures. The devices are used wherever a safe, robust and low-maintenance monitoring of flow values is required. This includes e.g. cooling circuit monitoring, monitoring of the flow rate of process fluids, monitoring of metering processes or also for pump protection in process and factory automation.

Request for a quote

VILLINA LLC

Russia

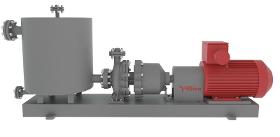

Centrifugal pumps have well-known advantages such as uniform pumping without surges, the ability to create high pressures at low pump rate in multi-stage designs, long service life and others. However, operation of centrifugal pumps requires building positive pressure (pressure boosting) upstream of the inlet suction pipe for the following reasons: to fill the pump body with the pumped fluid in order to avoid a "dry start" to prevent cavitation during pump operation. Classic methods for creating pressure boosting before centrifugal pumps can be: installation of a tank from which the fluid is pumped, several meters above the axis of the pump shaft and placing the pump in the draw-off sump; inclusion of an additional vacuum pump into the process, which is capable of building the desired pressure boosting of several metres. HOW IS THE PROBLEM OF CREATING A PRESSURE BOOSTING IN MODERN SELF-PRIMING CENTRIFUGAL PUMPS SOLVED? Villina company offers you Villina self-priming GNGC series

Request for a quote

RHEONICS GMBH

Switzerland

Single instrument for simultaneous process density (specific gravity), viscosity and temperature measurement Compact form-factor for simple installation Real-time, stable, repeatable and reproducible measurements in Newtonian & non-Newtonian fluids Measures kinematic and dynamic viscosity All metal (316L Stainless Steel) construction Completely insensitive to mounting conditions Operational to 7500 psi (500 bar) and 575°F (300°C) Threaded, flanged and sanitary process fittings Easy to clean, no maintenance or re-configurations needed Scale across multiple locations/installs without application re-engineering

Request for a quote

RHEONICS GMBH

Switzerland

Single instrument for simultaneous process density, viscosity and temperature Monitor even gas density and viscosity Accurate measurement in the harshest of conditions Operational to 15,000 psi (1000 bar) & 400 °F (200°C) Full Titanium Grade 5 construction High accuracy for gas density and viscosity monitoring Available for LNG and natural gas density monitoring

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Fluid meters - Import exportNumber of results

6 ProductsCountries

Company type