- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- flow measurement

Results for

Flow measurement - Import export

ENVEA

France

Electrodynamic flow sensor for the measurement of low flow rates from 0 to 100 kg/h. For pipe diameters up to 1 m. Ideally used in leanphase conveying. In free fall conditions with at least 2 m/s drop speed. • suitable for very low concentrations • ceramic coating prevents sensor wear

Request for a quote

SUVIS GMBH

Germany

The particle image velocimetry (PIV) is an optical noninvasive working flow velocity measurement method. The flow field is made visible by introducing into the fluid small buoyancy neutral particles – the so called tracers. The particle flow then is illuminated with the aid of a light sheet and recorded at two defined different times within a small time interval with a digital camera. Because the particle move within this time interval with the flow, one can calculate the particles velocity by knowing its path between the two moments of illumination. The result is a velocity vector field of the flow. Here, we assume that the particles are small and follow the flow without any slip. Compared to local methods like LaserDopplerVelocimetry (LDV) with the ParticleImageVelocimetry one can reconstruct a whole flow region An extension of ParticleImageVelocimetry is the combination of PIV with thermometry (PIV/T).

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The BATCHFLUX 3100 is an electromagnetic flowmeter (EMF) for rotary or linear filling machines. It is the economical solution for filling applications with conductive liquids.Due to its unique ceramic measuring tube, the mag meter features good repeatability and long-term stability. The flowmeter has an ultra-compact lightweight housing ideal for the tight spaces in volumetric filling machines. It can be used for filling of water or carbonised drinks. The EMF is suitable for common CIP cleaning procedures.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

PROCESS DATA MEASUREMENT AND PROCESS CONTROL ON HIGHEST LEVEL AND NEARLY MAINTENANCE-FREEFollowing the user‘s request for easy maintenance and low susceptibility to slightly soiled water, the proflow mechanical - as a replacement for the current and widely used standard measuring variant with impeller or turbine - now makes mechanical measurement according to the differential pressure principle (without rotating parts) available. The sensors can be visualized via a protemp controller or connected to a PLC. A completely non-contact flow measurement based on the ultrasonic principle is available with the proflow ultrasonic. Robust flow measurement in consumer return line PT 1.000 temperature measurement in consumer return line 6 x 2 consumer channels 3/4“ female screw thread 1 x 2 main connection 1“ female screw thread Available in three temperature variants: operating temperature up to 100°C, up to 160°C and up to 180°C Max. flow rate each channel:: 25 l/min or 50 l/min

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

MULTI-ZONE TEMPERATURE CONTROL- AND MONITORING SYSTEM WITH NON-CONTACT FLOW MEASUREMENT. Due to the design, dimensioning and selection of the used components, enersave temperature control systems are the most efficient systems on the market with the highest flow rates at operating point. By using the frequency inverter, the already high basic efficiency is optimized and the pump characteristic curve will be optimally adapted to the respective operating conditions. The flow measurement of the individual temperature zones is carried out using noncontact measurement technology according to the ultrasonic principle.

Request for a quote

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

We offer you standardized complete systems for the measurement of volume & mass flows. We use measuring elements that have established themselves within previously built customer-specific test benches and convince with high measuring accuracy. The SMF® series of nozzle test benches has been specially developed for calibration with air. Critical nozzles are used as measuring elements. Up to 18 critical nozzles can be combined, depending on customer requirements. EP offers different designs for the register: Drum Design, Block Design & Register Design. Another variant is a mobile system: The EP SMF® - Mobile Flow Calibrator - a compact measuring system for flow calibration. EP Ehrler Prüftechnik manufactures single nozzles in the flow rate range from 0.005 to 2000 m³/h. In addition to our standard range, we also manufacture customer-specific nozzles that are perfectly designed for your application in compliance with DIN EN ISO 9300*.

Request for a quote

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

Based on years of experience in the field of test bench metrology in the automotive industry, EP develops test bench solutions for various applications. We build test benches for testing automotive components such as heat exchangers, intercoolers, filters, valves and others. These are test benches on which e.g. supplier parts for the automotive industry are tested in production. Our specialist knowledge of the industry makes us a strong partner in this area.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The Valve-Tronic Plus™ is designed for use in highly demanding industrial applications that require accurate flow control and measurement. It can function as a stand-alone controller for basic applications or become an integral part of a process control system for automatic flow control. FEATURES • Large LCD displays actual flow rate, totalized flow, valve position, alarms, and diagnostic messages • Field programmable engineering units • Magnetic sensor technology immune to problems related with dirty oil • Configurable to control based on rate of flow or valve position for applications where the Process Variable (PV) is Dew-point, Carbon Potential, etc. • Standard Modbus TCP for easy integration with control systems • Manual actuation of value possible • Field calibration for null and span • Advanced polynomial calibration for high accuracy over the entire range of the meter • Built-in Web Server with remote access to device • Full PID setpoint control The VALVE-TRONIC Plus™...

Request for a quote

ENVEA

France

Continuous flow measurement of powder or granules in high pressure densephase conveying. Designed to measure solid flows during pneumatic dense phase transport. The sensor measures density and speed. • pressureresistant up to 64 bar • maintenancefree • contactless • ATEX category 3 approved

Request for a quote

ENVEA

France

Continuous solids mass flow measurement in densestream conveying and high levels of throughput. Designed to measure solid flows during pneumatic dense phase transport. The sensor measures density and speed. • unlimited throughput volumes can be measured • no wear thanks to the ceramic inner pipe • simple retrofitting • maintenancefree

Request for a quote

ENVEA

France

Measurement of the volume flow, especially in dusty applications. Easy installation on existing ducts, no venturi or similar conversions are required. • easy to retrofit • no calibration necessary • output in operating cubic metres • suitable for all diameters and geometries

Request for a quote

ENVEA

France

Microwave sensor for contactless monitoring of material flow in air slides. • easy to install • easy to retrofit • gives trending information by 4 20 mA output • immediate alarm when flow is interrupted

Request for a quote

ENVEA

France

Electromagnetic flowmeter, designed to measure bulk material flows up to 300 t/h. The meter has no mechanical parts in the flow, is 100% dustproof and erosion free because of ceramic inner pipe. • arbitrary mounting position (inclined/free fall) • low headroom required • easy to calibrate

Request for a quote

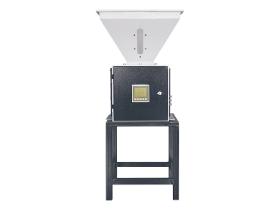

ROBINSON CO.

Turkey

The flow scale is ideal for mechanical conveying systems with continuous flow measurement. It is also used with vertical systems and belt conveyors. The ability to work in very small spaces due to its compact design, The ability to be easily installed, It is not affected by dust due to the measurement sensor being out of the process, Flow measurement and control during flow, flow measurement and control between 0.5-40T / S. Motor controlled feeding and integrated measurement system, dosing, flow rate control in percentage or kg / h, precise flow measurement and control with Loadcell, There is no pneumatic control in Akar scale. The system has no air dependency. The desired product mixture is made according to the values entered from the flow scales placed under the wheat silos from the computer or the operator panel on the scale.

Request for a quote

ROBINSON CO.

Turkey

Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories Features & Advantages ◾ Complete control of the PLC ◾ High speed weighing and long service life thanks to the stainless steel load cell ◾ Special protection class IP 67 ◾ Easy calibration ◾ Various feeding system according to the type of product to be weighed ◾ Data information based on actual weight values ◾ Bulk flow measurement as required Show in total value weighed ◾ The ability to work individually or in a network

Request for a quote

ROBINSON CO.

Turkey

Instantly measure and display of humidity and hectoliter of wheat Calculation of water flows according to the required humidity. Automatic water dosage according to the calculated water flow value Automatic water dosage according to the wheat flow variation by the connection of wheat flow control or measure unit Alarms of failure More than one humidity – hectoliter measuring unit and water the dosage unit can be controlled by the PLC control unit.

Request for a quote

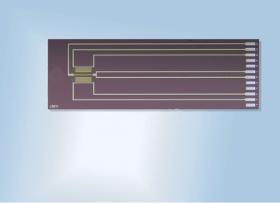

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG FS2 flow sensors are applicable in gas and offer excellent long-term stability. In addition to measuring flow rates, the FS2 gas flow sensor is able to detect flow direction with outstanding sensitivity. Further advantages of the FS2 thermal mass flow sensor include: — Simple signal processing — Simple calibration — Bare sensor resists up to +450 °C (customer specific) — Stable platinum technology — Excellent reproducibility — No moving mechanical parts — Customer-specific sensor available upon request The IST AG FS2 flow sensors are optimal for measuring gas flow and direction.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The SFS01 is particularly suitable for low flow velocities up to 3.5 m/s (in gases). It shows very fast measurement results of the flow rate as well as the flow direction. The Silicon Flow Sensor SFS01 offers three main characteristics: — Very fast response time <5 ms — Very low energy consumption — Easy system integration including temperature compensation Well-adapted channel geometries allow the performance of the sensor to be optimally aligned to the desired application. The SFS01 flow sensor is ideally suited for space-limited applications, but can also be easily upgraded to complete ready-to-use systems. Suitable application areas for the SFS01 flow sensor are flow measurements in battery-operated / portable devices, air conditioning technology (HVAC), automation technology as well as process and control engineering.

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

For measuring flow rates using a symmetrical heater design and having an excellent sensitivity and reproducibility. It has a plastic housing for fast mounting into a flow channel

Request for a quote

HANS TURCK GMBH & CO. KG

Germany

Flow monitoring Flow monitoring is a procedure that demands a reliable and reproducible surveillance of limit values and flow patterns. Flow sensors detect critical deviations of the flow rate of liquid and gaseous media. Typical areas of application are the monitoring of cooling circuits in welding applications for example, protection against dry running of pumps, as well as the flow monitoring in air ducts and air conditioning equipment. Because of the calorimetric mode the media temperature is also monitored. Flow rate measurement In addition to reproducibility, flow-rate measurement demands a defined degree of accuracy. The flow meters continuously and accurately measure a defined volume of a fluid per unit of time and are suitable for applications where qualitatively consistent process results and a steady supply of fluids is essential. We offer flow meters with calorimetric, magnetic-inductive and Vortex measurement principle for various areas of application.

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG MicroFlowSens (MFS) technology was developed for fast flow measurements. Due to the membrane system, the thermal mass is reduced to the minimum resulting in a very fast response time and low power consumption. In addition to measuring flow rates, the MicroFlowSens offers an outstanding sensitivity and is able to detect flow direction. The MFS flow sensor is optimal for limited space system integration and is available as integrated sensor on a PCB. Further advantages of the MFS thermal mass flow sensor include: — Excellent solution for applications with high flow rates and fast response time in CTA mode — Very high measuring dynamic with CTA mode (10'000'000 : 1) without bypass — Excellent for the measurement of very low flow rates and leakage detection with bridge mode — High chemical resistance against aggressive gases and vapors — Different sensitivities, circuit topologies available — Detection of flow direction — Customer-specific sensor layout upon request

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG FS7 thermal mass flow sensors are the successors of the FS5 flow sensors and exhibit a symmetrical heater design and enhanced sensitivity. The FS7 flow sensor is applicable in gas and offer excellent long-term stability. The small thermal mass of the FS7 sensor provides a fast response time. Additionally, the standard FS7 sensor is also available with a housing which is easily implemented into various applications. Further advantages of the FS7 thermal mass flow sensor include: — Easy adaptation in various applications and housings — Excellent long-term stability — Simple signal processing — Simple calibration — Stable platinum technology — Excellent reproducibility — Customer-specific sensor available upon request. The IST AG FS7 flow sensors are optimal for measuring gas flow in various flow applications.

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG FS7.4W gas flow sensor has been developed for applications with temperatures up to 400 °C. The design of the FS7.4W is based on the FS7 design which offers a symmetrical heater that enhances sensitivity. The FS7.4W flow sensor is applicable in gas and offers excellent long-term stability. The small thermal mass of the FS7.4W sensor provides a fast response time. Further advantages of the FS7.4W thermal mass flow sensor include: — Easy adaptation in various applications and housings — Excellent long-term stability — Simple signal processing — Simple calibration — Stable platinum technology — Excellent reproducibility — Customer-specific sensor available upon request The IST AG FS7.4W flow sensors are optimal for measuring gas flow in various flow applications.

Request for a quote

ENVEA

France

A simple solution to identify failure of a fabric filter baghouse, cartridge filters or cyclones. Ideally suited to applications from 0.1 mg/m³, it provides an immediate alarm in case of a filter break. • detects all dust types • relay alarm output • usable in clean gas and any metallic dust channels • very simple and fast retrofitting • immediate detection of filter damages • simple commissioning (plug & play) • excellent price/performance ratio

Request for a quote

LUTZ PUMPEN GMBH

Germany

The flowmeter with touchscreen display and backlighting convinces with its simple, demand-oriented display and operability, the multilingual interface and the compact design. Thanks to the rotating Oval gear meter and the magnets placed on the measuring wheels, it enables accurate measurement of the volume flow and at the same time measures non-flammable liquids such as Paints, lacquers, mineral oils, acids, alkalis, mineral oils and solvents as well as highly flammable liquids precisely, quickly and above all efficiently. * Optionally in explosion-proof design * Measurement according to the oval wheel principle * High measuring accuracy due to overtravel correction * Low pressure losses in the system * Touch screen display with self-explanatory, multilingual user interface * Relay module for quantity preselection can be retrofitted at any time * Approved according to ATEX Directive 2014/34/EU, category 2

Request for a quote

LUTZ PUMPEN GMBH

Germany

The flow meter with touchscreen display and backlighting impresses with its simple, needs-based display and operability, multilingual interface and compact design. Thanks to the rotating oval wheel meters and the magnets placed on the measuring wheels, it enables precise measurement of the volume flow and measures non-flammable liquids such as alkalis, mineral oils, hydrocarbons and solvents as well as highly flammable liquids precisely, quickly and, above all, efficiently. * Optionally available in explosion-proof design * Examples of media: Paints, varnishes, mineral oils, acids, alkalis, mineral oils, solvents * Measurement according to the oval gear principle * High measuring accuracy due to overrun correction * Touch screen display with self-explanatory, multilingual user interface * Relay module for volume preselection can be retrofitted at any time * Approved in accordance with ATEX Directive 2014/34/EU, Category 2

Request for a quote

LUTZ PUMPEN GMBH

Germany

The flowmeter with touchscreen display and backlighting convinces with its simple, demand-oriented display and operability, the multilingual interface and the compact design. Thanks to the rotating Oval gear meter and the magnets placed on the measuring wheels, it enables accurate measurement of the volume flow and at the same time measures non-flammable liquids such as alkalis, paints, lacquers, mineral oils, solvents, hydrocarbons and solvents as well as highly flammable liquids precisely, quickly and above all efficiently. * Optionally in explosion-proof design * Measurement according to the oval wheel principle * High measuring accuracy due to overtravel correction * Low pressure losses in the system * Touch screen display with self-explanatory, multilingual user interface * Relay module for quantity preselection can be retrofitted at any time * Approved according to ATEX Directive 2014/34/EU, category 2

Request for a quote

LUTZ PUMPEN GMBH

Germany

Easy to operate, compactly built and quick to mount on all Drum- and container pumps: the new Lutz Flow Meter TR3 in PP or PVDF. A handy meter that you can "count on" in any situation. The symmetrical measuring chamber allows it to be used for all flow directions and measures low-viscosity, non-flammable media precisely, quickly and, above all, efficiently. * PP for neutral and aggressive media * Media examples: Glycol, ferric chloride, hydrochloric acid, phosphoric acid, etc. * Two 1.5 V batteries (AAA) interchangeable Features & Advantages * Measurement according to the turbine wheel principle * Display of partial and total quantity * Variable display orientation * Mobile on a Drum pump or with nozzle connection * Measuring range from 5 l/min - 120 l/min * Easy battery change

Request for a quote

SUVIS GMBH

Germany

For the generation and production of a spray the knowledge of information like the desired droplet size and its distribution is of fundamental importance. In order to characterise a spray correctly, one has to know the droplet size distribution of the droplets, which were generated out of a given liquid. In many applications it is desired to produce very small droplets. For the design and lay out of inhalers for example, it is necessary to achieve droplet sizes not larger than approximately 10 μm to be absorbed by the lungs. When one designs an atomisation nozzle in view of the desired droplet size distribution, one has to make sure via measurements, that the nozzle is really able the produce the expected droplet size distribution within an acceptable uncertainty range. Besides the droplet size distribution, the droplet velocity is an important parameter since it is a measure of the droplet momentum.

Request for a quoteResults for

Flow measurement - Import exportNumber of results

215 ProductsCountries

Company type

Category

- Measurement and regulation equipment and instruments - output and flow (115)

- Flow meters (52)

- Sensors (17)

- Flowmeters (15)

- Gold and silver plating - steels and metals (14)

- Testing equipment (6)

- Measurement - Equipment & Instruments (4)

- Plastics - machines and material for industry (4)

- Flour milling - machinery and equipment (3)

- Measurement and control instruments (3)

- Measurement and regulation equipment and instruments - pressure (3)

- Precision measuring instruments (3)

- Calibration equipment (2)

- Electric motors and parts (2)

- Presses, hydraulic (2)

- Yardsticks, metersticks, tape measures and rulers (2)

- Beverage industry - machinery and equipment (1)

- Cameras, cinematographic (1)

- Ceramic, components - electric (1)

- Chemicals - Basic Products & Derivatives (1)