- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- fibre-reinforced composites

Results for

Fibre-reinforced composites - Import export

P.J. PRAUSE DUROTEC GMBH

Germany

The laminated epoxy-fiberglass material Scotchply™, developed and patented in 1954 by the 3M company, has been processed by Prause Durotec into high performance leaf springs since 1974. Today, using the same improved fibre reinforced composite material, Prause Durotec processes and distributes composite leaf springs under the protected and registered product name S-Ply®.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit centerless grinding wheels can grind workpieces from a few millimeters to several meters in length with maximum precision and cost-effectiveness, ideal for large series of identical parts. Centerless grinding wheels are notably thick compared to their diameter. Special pressing processes, adapted specifications, and sometimes split grinding wheels ensure homogeneous density distribution. Tyrolit offers a complete assortment of grinding wheels, regulating wheels, and dressing tools. Continuous product development guarantees high stock removal, tight tolerances, and fine surface results. Resin-bonded CBN grinding tools with a fiber-reinforced composite carrier body offer up to 80 percent less weight and better absorption properties, enhancing grinding results and tool life. Vitrified-bonded wheels use innovative sintering technology to prevent abrasive grain breakage. Lightweight diamond wheels are available for centerless through-feed grinding, gentle on machine spindles.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MALVIN SRL

Italy

Macroporous Eco-frendly Bio-plaster based on natural hydraulic lime, NHL 3.5 or NHL 5 according to EN 459-1, for plasters for dehumidification, for indoors and outdoors. Available fibre-reinforced with a special composition of polypropylene fibres specially formulated "FR" type and repellent type "I". Recyclable as inert at the end of life. Specifically for the preservation of historical artefacts. Ideal for the rehabilitation and recovery of old and new walls, internal and external, subject to humidity for capillary ascent and in the presence of efflorescence of salts, underground environments not subject to infiltration of water, buildings of historical interest, churches and In any case a definitive and natural dehumidifying cleansing treatment is necessary. Anab-ICEA Certified according to UNI EN ISO 14024 Environmental labelling type I.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

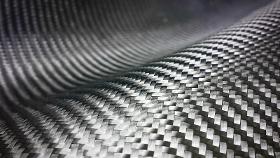

Fiber-reinforced composites are in demand in all high-end industries in which light weight and at the same time high durability under dynamic load ensure competitive advantages Efficient and reliable press technology for fibre composite plants Whether glass fibre reinforced plastic (GRP) or carbon fibre reinforced plastic (CFRP): The valuable material is mainly used in application fields where weight reduction, fuel consumption,anti-corrosion characteristics and other stress resistency feauters are in focus. The name Siempelkamp also stands for solid and precise technologies in these presses and handling systems as well as for high flexibility due to its suitability for all composite applications such as sheet molding compounds with glass or carbon fibers (SMC), prepreg compression molding with short, long or continuous fibers (PCM), resin transfer molding (RTM), and thermoplastic forming.

Request for a quote

KELTEKS

Croatia

solidian REBARs are combining highstrength fibers with extremely resistant resins in the production process named pultrusion. Here carbon or glass fibers are oriented extremely straight, impregnated by resin and hardened. solidian REBARs are realizing unbelievable high and durable loadbearing capacities up to most extreme demands. This is the result of the combination of the straightness of the fibers and the selectable big diameters of the crosssection. As such solidian REBARs are accessible onsite. So they are the ideal noncorrosive substitution for metallic reinforcements for everybody who is interested in economical and ecological sustainability. corrosionresistant thinner concrete cover, longer service life, lower refurbishment costs reduced weight with higher tensile strength high tensile strength lower overall construction costs electronically isolating and nonmagnetic sustainable and resourcesaving fewer

Request for a quote

KELTEKS

Croatia

solidian REBARs are combining highstrength fibers with extremely resistant resins in the production process named pultrusion. Here carbon or glass fibers are oriented extremely straight, impregnated by resin and hardened. solidian REBARs are realizing unbelievable high and durable loadbearing capacities up to most extreme demands. This is the result of the combination of the straightness of the fibers and the selectable big diameters of the crosssection. As such solidian REBARs are accessible onsite. So they are the ideal noncorrosive substitution for metallic reinforcements for everybody who is interested in economical and ecological sustainability. corrosionresistant thinner concrete cover, longer service life, lower refurbishment costs reduced weight with higher tensile strength high tensile strength lower overall construction costs electronically isolating and nonmagnetic sustainable and resourcesaving fewer

Request for a quote

KELTEKS

Croatia

solidian REBARs are combining highstrength fibers with extremely resistant resins in the production process named pultrusion. Here carbon or glass fibers are oriented extremely straight, impregnated by resin and hardened. solidian REBARs are realizing unbelievable high and durable loadbearing capacities up to most extreme demands. This is the result of the combination of the straightness of the fibers and the selectable big diameters of the crosssection. As such solidian REBARs are accessible onsite. So they are the ideal noncorrosive substitution for metallic reinforcements for everybody who is interested in economical and ecological sustainability. corrosionresistant thinner concrete cover, longer service life, lower refurbishment costs reduced weight with higher tensile strength high tensile strength lower overall construction costs electronically isolating and nonmagnetic sustainable and resourcesaving fewer construction materials are required and the

Request for a quote

KELTEKS

Croatia

solidian REBARs are combining highstrength fibers with extremely resistant resins in the production process named pultrusion. Here carbon or glass fibers are oriented extremely straight, impregnated by resin and hardened. solidian REBARs are realizing unbelievable high and durable loadbearing capacities up to most extreme demands. This is the result of the combination of the straightness of the fibers and the selectable big diameters of the crosssection. As such solidian REBARs are accessible onsite. So they are the ideal noncorrosive substitution for metallic reinforcements for everybody who is interested in economical and ecological sustainability. corrosionresistant thinner concrete cover, longer service life, lower refurbishment costs reduced weight with higher tensile strength high tensile strength lower overall construction costs

Request for a quote

KELTEKS

Croatia

solidian REMATs are produced of our noncorrosive and extremely strong solidian REBARs. The rebars are attached to each other by durable and solid injection molded crossing points forming the rigid mat. As a result, solidian REMATs are combining the same unbelievable mechanical properties of our solidian REBARs with the efficient handling of a robust mat on site. You do not need to knot together with your rebars in your prefab plant or construction site saving time and money. The solid injection points are enabling that you can walk on solidian REMATs. So what is the argument to still use steel or stainless steel? corrosionresistant thinner concrete cover, longer service life, lower refurbishment costs reduced weight with higher tensile strength high tensile strength lower overall construction costs electronically isolating and nonmagnetic sustainable and resourcesaving fewer construction materials are required and the service life is increased

Request for a quote

KELTEKS

Croatia

solidian REMATs are produced of our noncorrosive and extremely strong solidian REBARs. The rebars are attached to each other by durable and solid injection molded crossing points forming the rigid mat. As a result, solidian REMATs are combining the same unbelievable mechanical properties of our solidian REBARs with the efficient handling of a robust mat on site. You do not need to knot together with your rebars in your prefab plant or construction site saving time and money. The solid injection points are enabling that you can walk on solidian REMATs. So what is the argument to still use steel or stainless steel? corrosionresistant thinner concrete cover, longer service life, lower refurbishment costs reduced weight with higher tensile strength high tensile strength lower overall construction costs electronically isolating and nonmagnetic sustainable and resourcesaving fewer construction materials are required and the service life is increased

Request for a quote

KELTEKS

Croatia

solidian REMATs are produced of our noncorrosive and extremely strong solidian REBARs. The rebars are attached to each other by durable and solid injection molded crossing points forming the rigid mat. As a result, solidian REMATs are combining the same unbelievable mechanical properties of our solidian REBARs with the efficient handling of a robust mat on site. You do not need to knot together with your rebars in your prefab plant or construction site saving time and money. The solid injection points are enabling that you can walk on solidian REMATs. So what is the argument to still use steel or stainless steel? corrosionresistant thinner concrete cover, longer service life, lower refurbishment costs reduced weight with higher tensile strength high tensile strength lower overall construction costs electronically isolating and nonmagnetic sustainable and resourcesaving fewer construction materials are required and the service life is increased

Request for a quote

BAUENZ TECHNOLOGY LTD

United Kingdom

Replaces metal fittings. Does not magnetize, does not conduct electricity. Not a "bridge of cold". Composite fiberglass reinforcement is elastic. Fiberglass is stronger than steel bars. If we compare rods with the same diameter, then the ability to withstand tensile forces in metal reinforcement is 490 MPa, and in composite reinforcement - 800-1300 MPa. Compared to metal reinforcement of the same diameter, fiberglass reinforcement is more than 2 times stronger at breaking.

Request for a quoteResults for

Fibre-reinforced composites - Import exportNumber of results

16 ProductsCompany type