- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- dosing machines for chocolate

Results for

Dosing machines for chocolate - Import export

FORMEX MAQUINARIA

Spain

MACHINE CHARACTERISTICS: •Production line consisting of four stations: - Two automatic injectors. - One automatic dosing machine for chocolate coating. - Unit for spreading the topping on top of the coating. •A single urn keeps the injectors and the dosing machine heated, so that the product is kept at a stable temperature at which the dosing is smooth and trouble-free. •The line is no more than 5 metres long and can be operated by a single person at the start of the conveyor. •A double conveyor belt system moves the trays with the completed product to the start of the line. ADVANTAGES •High degree of automation in a small space, 5 metres. •Handled by a single operator. •Uniformity in the product.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Volumetric cup fillers enable the volumetric dosing of granular products. They can be fitted to all models of vertical form fill and seal machines and are offered in two series: 6 cups or 12 cups. Both models are equipped with a feed hopper with controlled outlet, a product level sensor, a series of cups made of food-grade material, a fixed lower cup carrier and, in automatic mode, a height-adjustable upper cup carrier with cup level sensor. The product is unloaded by gravity at the inlet of the packaging machine and, for fine products, the unloading system is equipped with a flap that prevents the product from spilling.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

This range of linear checkweighers is designed to fit all types of packaging machines, tray conveyors or simply for manual bag filling. These scales are compatible with a wide range of products: - Sweets - Cakes - Chocolate - Coffee - Rice - Detergent - Nuts and bolts - Confetti ... All parts that come into contact with the product are made of food-grade stainless steel and are easily removable.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

Our ecoPEN XS is a true volumetric dispensing system that applies the smallest amounts of singlecomponent fluids – for highprecision dispensing technology. Thanks to the proven endless piston principle, watery to pasty liquids are perfectly dispensed. A clean, processreliable dosage is achieved regardless of fluctuations in viscosity. - Dimensions (without cartridge and holder): length 178 mm, width 22 mm, depth 65 mm - Weight (without cartridge and holder): 175 g - Operating pressure: 0 - 6 bar - Max. dispensing pressure: 20 bar - Self-sealing: Approx. 2 bar - Viscosity: watery to pasty - Volume flow: 0.0044 - 0.35 ml/min - Min. dispensing quantity: 0.25 µl - Dosing accuracy: ± 1% - Stator material: vidur-C1 - Material inlet: Luer-Lock adapter for cartridge (cartridge can be rotated 360°) / Adapter for hose connection (Ø - 3mm) - Material outlet: Luer-Lock (patented) - Wetted parts: POM / vidur-C1 / stainless steel / HD-PE - Repeatability: > 99 %

Request for a quote

FERPLAST SNC

Italy

FLG SERIES AUGER DOSING SYSTEM FOR POWDERS Vertical augervolumetric dosingfor non-sliding powdersuch as flour, cocoa, sugar, ground spices, coffee, finely ground, chemicals, premixedbuilding,ice creamor sorbet, etc. Capacity from 100 to 5000 ml - Rugged stainless steel with basic overview - Product loading hopper in stainlesssteel AISI304 with inspection hatch - Start with electric-operated pedal - Electrical panelwith PLC

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-L 3 / 18 barrel emptying system offers a modern way of emptying containers.The connection with the ViscoTec VMP dispenser series for the removal of the medium offers the following advantages: - container sizes from approx. 50 l to 300 l - viscosities of approx. 80,000 - 2,000,000 mPas - very low shear stress of the medium - very low pressure load of the medium (max. 18 bar) - removal of materials loaded with fillers - no backflow within the sampling pump - electrical control of the pump with pressure control - valve-free pump system - no material pressure reducer necessary due to electronic pressure adjustment - very good residual emptying (less than 1% residue) - electronic "empty" and "almost empty" message Application: Removal of materials directly from the delivery container, e.g. silicones, adhesives, resins, greases, colour pastes, metal-filled pastes (Cu and Ni solder pastes, Al and Ag pastes) - supply of media to dispensers

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

▪ Modular setup with five different available dispenser sizes on each side ▪ Static mixing of two materials with same or different viscosities ▪ Adjustment of the desired mixing ratio by adjusting the speed ratio of both dispensers ▪ Volumetric dosing, regardless of viscosity ▪ For low to high viscosity materials ▪ Particularly suitable for abrasive, filled or shear sensitive materials ▪ Continuous dosing, pulsation free ▪ Interior non-stick coated ▪ Linear relation between dosing volume and rotation speed ▪ Programmable suck-back prevents dripping or stringing of product ▪ Different rotor and stator materials available as standard ▪ Long service life due to application-specific rotor-stator combinations ▪ Easy cleaning and maintenance due to quick assembly and disassembly options ▪ Mixing ratio 1:1 - 100:1 ▪ Volume flow of 0 - 1,300 ml/min (depending on mixing ratio, material and dispenser combination)

Request for a quote

NOVELTY STEEL

Turkey

A chemical dosing system comprises a comprehensive array of equipment designed for dosing, mixing, liquid transport, and automated control. It may also be referred to as a chemical feed system or dosing apparatus. This system finds application in various sectors such as power plant raw water treatment, boiler feed water management, oil field ground gathering and dehydration transportation systems, petrochemical dosing operations, and wastewater treatment processes.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

The auger feeder series enables the volumetric dosing of powdery products with fine granulation, which can sometimes present problems of compactness, dust content and variable density, such as cocoa, curry and other "powdery" products. The various problems associated with processing the products are solved, starting with feeding the product through a hermetically sealed hopper equipped with a level sensor and a motorised agitator. The screw, made from a single solid mass, has an electronically controlled speed by means of a servo motor, which allows the use of acceleration and deceleration ramps that ensure an immediate screw stop, thus guaranteeing optimum dosing accuracy.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-XM barrel emptying system with volumetric pump based on the endless piston principle. Your advantages: - for medium to high viscosity products (up to 7,000,000 mPas) - suitable for abrasive, shear-sensitive or lumpy materials loaded with fillers - clean wiping of the inside wall of the barrel due to follower plate with special sealing lip - suitable for cylindrical, ribbed or slightly conical barrels, plastic containers or containers with inliners - no lateral squeezing of the medium, as the follower plate is guided almost without pressure - discharge speed electronically adjustable - easy handling - pulsation-free conveyance/discharge - Residual quantity in the barrel: < 1% - compact design Application: Withdrawal of products directly from the delivery or storage container, e.g.: Tomato paste, honey, fats, icing, mascara and much more. pressure-controlled or level-controlled feeding of the products to filling machines or mixing processes.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

▪ Automated emptying system for containers up to approx. 30 liters ▪ Volumetric conveying progressive cavity pump based on the endless piston principle ▪ Pulsation-free and precise emptying and material supply to 1C and 2C dispensing systems ▪ In redundant dosing systems applicable ▪ For medium to high viscosity materials ▪ For structure sensitive, filled, abrasive materials ▪ Application for cylindrical or slightly conical metal and plastic containers ▪ Housing for machine safety and protection against dirt contamination ▪ Automatic retraction and venting the container as well as detection of media surface ▪ 4“-Touch panel with function keys for comfortable setting and parametrization of the system ▪ Externally controllable via Profinet interface ▪ Continuous determination of the position of the follower plate and level monitoring ▪ Adjustable pressure reduction for longer pauses

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

▪ Continuous volumetric and pulsation-free dosing regardless of viscosity ▪ For low viscosity and self-levelling materials (e.g. trickle resins) ▪ Low wear solution due to avoidance of material contact at shaft seal ▪ Uninterrupted production thanks to material reservoir with up to 350 ml usable volume ▪ Pressure and temperature sensor including sensor holder at pump outlet ▪ Level programmable using analog level sensor ▪ Filling under atmospheric pressure ▪ Optional connection for process gas (max. 0.2 bar pressure) ▪ Dispenser holder for easy and stable installation ▪ Increased process reliability due to integrated safety device ▪ Dividable rotor assembly for easy & fast replacement and low spare part costs

Request for a quote

LUTZ PUMPEN GMBH

Germany

The Lutz-Jesco dry material feeders are precise and reliable devices for volumetric conveying of pourable substances. These devices consist of self-supporting welded constructions made of high-quality stainless steel sheet, which ensures their robustness and durability. Available in various conveying capacities, the dry material feeders offer flexible adaptation to different requirements and areas of application. They are equipped with hollow screws (screw spindles), which ensure even and continuous material transport. Thanks to this technology, they can feed a wide range of bulk materials, including fine dust particles, pellets, flakes and short fibres. Lutz-Jesco dry material feeders are ideal for industrial applications where precise dosing is required, such as in the chemical industry, food processing and many other sectors.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoTec dosing and filling pump RD-Hygiene for food and cosmetics is a volumetric pump based on the continuous piston principle. It is ideally suited for discontinuous or continuous pulsation-free dosing of viscous, structure-sensitive and solids-laden media. Thanks to the high-quality ViscoTec dispensers, high-precision dosing applications can be realized in the food and cosmetics sector. The systems are used e.g. in the bakery and confectionery sector for decoration. Typical doses are icing or fondant, but also fillings such as vanilla or chocolate cream. Your advantages: - Specially adapted filling tubes for a wide variety of filling applications - Application and dosing in automated systems - Low to high viscosity as well as abrasive, shear-sensitive or lumpy media - hot and cold filling - Optimum results for CIP/SIP (Cleaning in Place/Sterilisation in Place) cleaning

Request for a quote

FORMEX MAQUINARIA

Spain

•Continuous dosing as the belt advances. •Manual adjustment of the dosing head height, which lowers automatically for each dose. •Adjustable belt speeds on the screen. •The dosing control is managed by a servomotor system that gives the machine greater speed, smoothness and precision to work with a wide variety of densities. •Thanks to the servomotor the user can control the dosage quantity electronically as well as loading and/or unloading speeds. •Anti-drip movement with suction of the product. •All this with great precision and with the facility to pre-record these parameters in more than 100 recipes.

Request for a quote

PROTEC POLYMER PROCESSING GMBH

Germany

The SOMOS® Gramix ExactDos dosing system is specifically designed for ultra-small volumes from a minimum throughput of 200 g/h (approx. 3.3 g/min) and can be combined with any continuous dosing unit.

Request for a quote

PROTEC POLYMER PROCESSING GMBH

Germany

SOMOS® Volmix from ProTec is a highly accurate volumetric dosing and mixing system. Volmix stands for VOLumetric dosing and MIXing. The system supplies injection molding machines as well as extruders or blow molding machines with throughputs of up to 2,500 kg/h. A high-accuracy small-volume dosing unit for regrind for a throughput as low as 150 g/h is available as an option.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KTW TECHNOLOGY GMBH

Germany

KTW SmartValve technology: Volume and exact dosing of aromas in beverage and liquid containers such as bottles, cans, beverage cartons, canisters

Request for a quote

MARIBELL TM

Ukraine

Hot Chocolate TM Tasarone is very popular hot drink for cafes, restaurants and for household applications. You can choose: - black hot chocolate - milk hot chocolate - vanilla hot chocolate Packing: plastic 1000g can or paper 1000g bag Send us your price request: irina.syrup@gmail.com Visit or web: www.maribell.com.ua

Request for a quote

SMARTMAK

Turkey

Chocolate Enrobing Line provides a practical and fast solution for dipping products with chocolate, such as dates, pastries, biscuits and various fruits such as strawberries. Chocolate can be used in liquid or granular form.

Request for a quote

ALKE MACHINERY ENGINEERING

Turkey

Using our equipment for chocolate production you can ; To produce a wide range of chocolate types in an one production line, Chocolate production in different colors and shapes, switch quickly from one product to another, To expand the diversity of the masses with each other and with wafer, cookies and other combinations by increasing the variety of forms, making filling and confectionery,Any mass can be used: chocolate, caramel, praline masses, nougat, halva, marzipan, dried fruits, fondant, soufflé, marmalade etc. Almost completely free from manual labor.

Request for a quote

ANATOLIAN FRUIT LTD.ŞTI.

Turkey

We produce Chocolate Coating Machines up to 100 Meters Band Length

ALKE MACHINERY ENGINEERING

Turkey

We produce enrobing machines of various capacities (pump or disk). The machines are adapted to work with natural chocolate or compound chocolate. Different belt widths on request. Detachable chocolate reservoir makes it easy to coat products in two different colors. (optional) Electrical panel on chocolate coating machine allows to adjust heat control, band speed control, thickness of chocolate coating and vibration Complete, bottom or top coating of the products.

Request for a quote

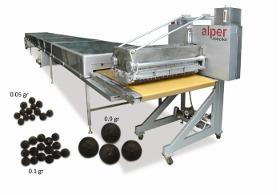

ALPER MAKINA CHOCOLATE PRODUCTION LINES

Turkey

rop Line Chocolate drop size can be adjusted between 0.05 to 0.9 gr Each drop has its own piston Depositor has high precision since dosing is done by servo-motors. Depositor hopper is double jacketed and temperature controlled Depositor has agitator Easy cleaning PLC controlled Capacity: 33-600 Kg/hour

Request for a quote

KADZAMA D.O.O.

Slovenia

Melanger is a universal machine for obtaining homogeneous masses from solid ingredients. Thanks to stone millstones and mixing scrapers, the melanger replaces three pieces of equipment from a large factory – mixing of ingredients (PREGRINDING), fine GRINDING (FINE GRINDING) and conching (CONCHE). Overall dimensions (LxWxH) - 550 x 450 x 550 mm; Weight-45 kg; Loading 7 kg; The minimum load is 4.5 kg; Power supply 220 V ~ 50/60 Hz; Power consumption 550 W / h Case Material Steel; Rotation speed 0-90 rpm

Request for a quote

ALPER MAKINA CHOCOLATE PRODUCTION LINES

Turkey

Cooling Tunnel – Our cooling tunnel is used for cooling chocolate coated biscuits,jelly, nougat, fondant and similar products. – Belt widths 400,600, 800,1000, 1200 mm – Cooling unit is in the middle part of the tunnel. Two blowers supply the necessary air current. – Tunnel temperature is controlled by a digital thermostat. – Tunnel temperature can be down to 0°C. – Belt sped is controlled by electronic frequency drive. – Covers are insulted. – The tunnel can be cleaned by opening the top covers. – Tunnel has a automatic belt adjustment system. – Sharp edged infeed. – Tunnel has scrapers

Request for a quote

DOSENSPEZIALIST GMBH - TIN BOXES FROM GEMANY

Germany

- samples available - finishing from 100 pieces - from stock available - fast delievry - comeptitive prices - European delivery

Request for a quoteResults for

Dosing machines for chocolate - Import exportNumber of results

29 ProductsCompany type

Category

- Dosing - machines and equipment (17)

- Cocoa and chocolate - machines and equipment (8)

- Dosing pumps (8)

- Weighing and dosing equipment (6)

- Bottling and filling - machinery and equipment (2)

- Beverages - concentrates and powders (1)

- Biscuit-making - machinery and equipment (1)

- Cakes and pastries, factory-baked (1)

- Food Processing (1)