- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- solder

Results for

Solder - Import export

ROTH ELEKTRONIK GMBH

Germany

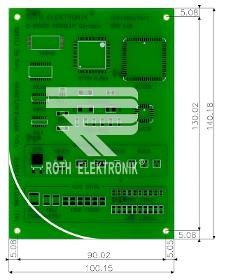

Epoxy fibre-glass FR4 1.50 mm Single-sided 35 µm Cu Without holes Hot air leveling (HAL-leadfree) with solder stop mask Component print PCB for machine assembly (Pick & Place) of Fine-Pitch QFP 256 QFP 256 4 x Size 100 x 140 mm

Request for a quote

ROTH ELEKTRONIK GMBH

Germany

Epoxy fibre-glass FR4 1.50 mm Single-sided 35 µm CU Without holes Hot air leveling (HAL-leadfree) with solder stop mask Component print PCB for 85 solder practices for SMD standard, fine pitch, and discrete components: version quantity PLCC 52, 68, 20 QFP 44, 84, 132, 184 sq. SOT23 3 x SOT89 2 x SOT143 1 x SOT233 1 x SO14 1 x SOM16 1 x SOL20 1 x Poti. 1 x DPAK 1 x Al. Kond. 6.30 mm 1 x Al. Kond. 4.00 mm 1 x Melf 2308 2 x Mini Melf 1206 6 x Tantal Chip Kond. A 1 Tantal Chip Kond. B 1 Tantal Chip Kond. C 1 Tantal Chip Kond. D 1 0402 Chip Kond. 10 x 0603 Chip Kond. 10 x 1206 Chip Kond. 10 x 0805 Chip Kond. 10 x 1210 Chip Kond. 7 x 2220 Chip Kond. 1 x 1812 Chip Kond 2 x TSOP32 1 x 5020 Schwingquarz 1 x Also very suitable for machine assembly (Pick and Place) Size 100 x 140 mm

Request for a quote

ROTH ELEKTRONIK GMBH

Germany

Epoxy fibre-glass FR4 1.50 mm Single-sided 35 µm Cu Without holes Hot air leveling (HAL-leadfree) with solder stop mask Component print PCB for 57 solder practices for implementation into the SMD surface mounted device: version quantity PLCC 20, 68 QFP 84 sq. TSOP32 1 x SO14 1 x SOM16 1 x SOL20 1 x SOT23 3 x SOT143 1 x SOT89 2 x SOT233 1 x DPAK 1 x Poti. 1 x Tantal Chip Kond. A 1 x Tantal Chip Kond. B 1 x Tantal Chip Kond. C 1 x Tantal Chip Kond. D 1 x 1206 Chip Kond. 10 x 0805 Chip Kond. 10 x 1210 Chip Kond. 6 x 1812 Chip Kond. 2 x 2220 Chip Kond. 1 x 2308 Melf 2 x 1206 Mini Melf 6 x Suitable for Pick & Place PCB for 57 solder practices for implementation into the SMD surface mounted device: version quantity PLCC 20, 68 QFP 84 sq. TSOP32 1 x SO14 1 x SOM16 1 x SOL20 1 x SOT23 3 x SOT143 1 x SOT89 2 x SOT233 1 x DPAK 1 x Poti. 1 x Tantal Chip Kond. A 1 x Tantal Chip Kond. B 1 x Tantal Chip Kond. C 1 x Tantal Chip Kond. D 1 x 1206 Chip Kond. 10 x 0805 Chip Kond. 10 x 1210 Chip...

Request for a quote

ROTH ELEKTRONIK GMBH

Germany

Epoxy fibre-glass FR4 1.50 mm Double-sided 35 µm Cu Hot Air Leveling (HAL lead free) Solder practice board for 11 different SMD components: 6x SO8 8x SO14 4x SO16w 4x SOT223-3 4x SO20 4x SOT89 22x SOT23 78x 1206 66x 0805 26x 1812 20x 2220 Size: 72.00 x 213.00 mm

Request for a quote

ROTH ELEKTRONIK GMBH

Germany

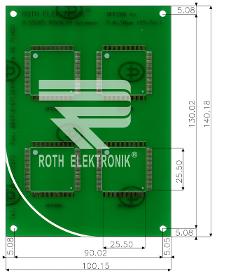

Epoxy fibre-glass FR4 1.50 mm Single-sided 35 µm Cu Without holes Hot air leveling (HAL-leadfree) with solder stop mask Component print PCB for solder practices for SMD Fine-Pitch QFP 208 QFP 208 4 x For manual soldering and very suitable for machine assembly (Pick & Place) Size 100 x 140 mm

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

TIG welding machine that combines robust industrial construction with excellent arc . Excellent arc performance - perfect HF ignition, stable, focused and fast arc (for pulsed and non-pulsed arc). Simple control panel - full control, easy configuration. Energy efficiency - PFC circuit, high efficiency, green mode. Portable - Small, lightweight PFC, 16A protection, 100m input cable, prepared for generator.

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

Input current at nominal output kW to duty cycle - 1.7 kW at 100% - 2.4 kW at 60% - 4.0 kW at 25% Input voltage 230 V 15% single phase Frequency 50/60Hz Welding current range 10-150A** Maximum open circuit voltage 90 Vdc Fuse (delayed action) or Circuit Breaker (characteristic D) AmP. 16A Input current cable 3 x 1.5mm2 Plug type (included with the machine) 16A / 250V Height x Width x Length (mm) 205 x 130 x 300 Weight (kg) 4.2 Type of metals able to weld: Steel cast iron stainless steel

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

SMART, COMPACT MULTI-PROCESS Lincoln Electric's Weld Pak 2000 is a complete multi-process continuous voltage arc welding machine ideal for welding thin sheets and repair and maintenance work. This machine is a perfect tool for light steel applications and is mobile, meaning the operator can easily move this MIG welding machine to any location in the workshop. Weld Pak 2000 is recommended for MIG/MAG applications, for arc welding with Innershield gas-free flux-cored core and applications with Rutile and Basic electrodes. This machine is designed to feed wire from 0.6 mm to 1.1 mm (steel, stainless steel and flux cored) on B300 and S200 coils. High quality welding performance that depends on a quality wire drive system. Lincoln Electric has equipped the Weld PAK with a professional feeder with large rollers. The Weld Pak 2000 is designed to meet Lincoln performance and reliability standards. : Compact design with a standard

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

Powerful and compact, great for MIG welding The Powertec 305C was designed around the need to satisfy our customers' demand for robust and robust compact MIG welders. Built as a true all-rounder, ideal for both thin sheet metal applications and light to medium construction work . Excellent start-up performance. Multi-step voltage knobs for precise adjustment. Excellent drive system with transmission roller Electronic feedback system on the wire drive ensures a constant wire feed speed. Equipped with large diameter wheels, push/pull bar and lifting eyes for total manoeuvrability. Meets IEC974-1, ROHS and CE standards for safety and reliability.

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

Discover the BesterMIG 200-S Inverter, a technological innovation that will radically change your approach to welding. Synergy technology transforms welding by automatically adjusting parameters . With Synergy, the difficulties of determining the ideal current, wire feed speed and correct material thickness are a thing of the past. This adaptive technology assists your welding needs, ensuring remarkable results with minimal effort. By reducing the margin for error, Synergy offers high quality welds with reduced costs. Increase your efficiency and productivity with automatic adjustments that save time and facilitate the welding process. Portable and compact multi-process equipment: MIG/MAG, FCAW, MMA and TIG Lift. Equipped with SYNERGY based on automatic selection of welding parameters Perfect solution for hobbyists and DIY enthusiasts: makes welding faster and more effective

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

It is a type of machine that is light, compact and easy to transport, it has the Anti-Stick function that prevents the electrode from sticking. Continuous dimming simplifies the current setup process. Furthermore, it is a powerful machine and can be used with electrodes between 1.6 - 4 mm. It works in a regulation field between 10 - 160 A. Its features also include: Hot Start (reduces the risk of sticking when the electrode and workpiece are cold, also facilitates priming and penetration) and Arc Force (keeps the intensity constant regardless of the arc length).

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

The Invertec 150S is suitable for a variety of applications and working environments. Its design was focused on providing excellent welding and starting behavior in a robust and reliable package. It is equipped with a unique set of features and capabilities to ensure perfect welding for your application. Robust and robust on the one hand, portable on the other, the Invertec 150S is light and easy to handle in any situation. Rugged Design – Unique rubber corners, metal casing and control buttons to withstand harsh environmental conditions. Premium Arch – Lincoln 's advanced technology and know-how guarantee performance every time. Power Surplus – Additional power for superior arc control. Soft and Crisp Mode – Selectable arc modes for different electrode types Self-adaptive arc force – For a stable arc with low spatter levels as standard. Integrated “Hot Start” for stable arc with lower splash level. Long cables: primary power extension cables up to 60 m.

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

If you want to explore MIG welding, Lincoln Electric's Handy MIG® machine is your ideal solution. Designed for flexibility and simplicity, this MIG welding machine is notable for its portability and ease of use, connecting to a 230V, 20 amp power source. Equipped with four voltage settings and a system for continuously adjusting the wire feed speed, the Handy MIG® is capable of welding mild steel from thin thicknesses up to 3.2 mm. The equipment is supplied almost ready to use, including almost all the accessories necessary to start MIG welding: a torch with mounted cable, an earth cable with clamp, a gas nozzle, a gas regulator with hose, a wire coil solid, contact tips, and a protective mask with filter plate and lens. You just need to add a shielding gas cylinder. Additionally, it includes a coil of self-shielded flux-cored wire, additional contact tips and a hammer with cleaning brush, expanding the functionality of the Handy MIG® for welding with and without gas.

Request for a quote

COMPANY TOR

Russia

The VIKING-500 PRO semiautomatic welding machine has two-piece design, is designed for power supply from a three-phase 380V network and produces 500A at a load of 60%. The design feature consists in a separate feeding mechanism that can be removed from the source to a control cable length of up to 15 meters. The device heats up the product to a minimum, which allows you to work with thin metals. An important feature is the presence of a two-shaft motor for the wire inch (four rollers), which significantly improves the stability and smoothness of the welding material feeding. Special software functions significantly increase the performance factor of the device. ... Key features of VIKING MIG 500 PRO: - digital control of the device; - advanced software settings; - dot welding mode 2T and 4T; - setting of a smooth drop of the termination current; - adjustable inductance; - forced gas purging; - forced wire inch; - the presence of a 36 V socket (for connecting a CO2 gas heating regulator

Request for a quote

COMPANY TOR

Russia

Welding inverters of the PRO series are light in weight and dimensions. The metal housing reliably protects the internal components, making it suitable for use on the construction site. Inverters are capable to operate with all brands of stick electrodes from 1.6 to 5 mm and 6 mm (VIKING 250PRO, VIKING 270PRO), including the УОНИ 13/55 brand. The minimum arc welding current is 30 A, the maximum one corresponds to the model. TP at maximum current for all models is 60%. Mains voltage range is 160 ... 260 V.

Request for a quote

COMPANY TOR

Russia

Welding inverters of the PRO series are light in weight and dimensions. The metal housing reliably protects the internal components, making it suitable for use on the construction site. Inverters are capable to operate with all brands of stick electrodes from 1.6 to 5 mm and 6 mm (VIKING 250PRO, VIKING 270PRO), including the УОНИ 13/55 brand. The minimum arc welding current is 30 A, the maximum one corresponds to the model. TP at maximum current for all models is 60%. Mains voltage range is 160 ... 260 V.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

COMPANY TOR

Russia

The VIKING TIG 315 AC / DC PRO argon-arc welding machine is a one-piece structure, designed for power supply from a three-phase 380 V network and produces 315 A at a load of 60%. Special software functions significantly increase the performance factor of the device: HOT-START, ARC-FORCE, ANTI-STICK functions. Specifications: Voltage: V380 Max power: kW5.5 Max current: A315 Operating mode: DC/AC Product class: Professional Burner operating mode: 2-stroke / 4-stroke Pulse mode: yes Availability of the button for saving the selected parameters “MEMORY”, allows you to program 10 parameters for each welding mode (AC/DC). PULSE welding mode is a pulsed consumable-electrode welding (Possibility to use both direct current (DC) and alternative (AC). Waveform selection function (available in AC mode). Dot welding mode 2T and 4T. Adjusting of smooth drop of the terminating current. Adjustable inductance.

Request for a quote

COMPANY TOR

Russia

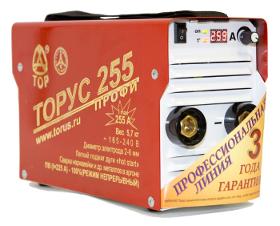

TORUS-255 has the widest possible range of arc welding currents (from 20 to 255 A), which makes it possible to use it both for welding very thin metals, including in the TIG mode (welding with non-consumable electrode), and for continuous welding of large metal structures using an electrode up to 6 mm in diameter. The operating margin in the ТОРУС-255 device is such that it can be effectively used not only for the MMA and TIG modes, but also in the surfacing and cutting modes. At the same time, the weight of the device itself is traditionally not big – only 5.7 kg. Like all devices of the ТОРУС line, ТОРУС-255 has increased reliability with all its maximum parameters. A 3-year manufacturer’s warranty is a guarantee of its high performance in the most severe operating conditions.

Request for a quote

COMPANY TOR

Russia

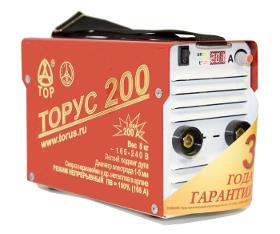

ТОРУС-200 is a modern welding inverter device based on a digital high-frequency mains voltage transducer. The device is designed for electric arc welding of low-carbon, alloy and stainless steels, it can operate in TIG and MMA modes. Obtaining high-quality welding joints does not require high qualifications from the employee, which is important for novice welders. In short-circuit mode, the device almost does not consume current, which allows it to be powered from petrol power units with a capacity of 4 kW (6 kVA) and a household network with slumps up to 165 V. ТОРУС-200, like other inverter welding machines of the ТОРУС line, allows you to get welding with stable parameters. It is characterized by: small weight – 5 kg, high performance factor and the ability to work with electrodes with a thickness from 1.6 to 5 millimeters. In addition, the ТОРУС-200 welding inverter is designed for continuous operation not only indoors, but also outdoors.

Request for a quote

COMPANY TOR

Russia

The Russian-manufactured inverter machine ТОРУС-320 is used for manual arc welding of metal blanks. The inverter has a functional control panel with a digital display that displays the main operating parameters. The metal housing is equipped with large ventilation holes in order to prevent overheating of internal components. The device is equipped with overload protection and voltage surge protection. The technologies applied during the manufacture of ТОРУС-320 devices allow performing any tasks in welding, surfacing and cutting metal structures for performing work with any kind of electrodes with a diameter of up to 6 mm and a maximum arc welding current of up to 320A (100% at 300A). The welding inverter machine can be used at low temperatures and reduced supply voltage.

Request for a quote

KGA ENCLOSURES LTD

United Kingdom

Product Features: • Choice of two primaries: Single primary 115VAC (187 Series) or Dual primary 115/230VAC (186 Series). • Either series operates on 50/60 Hz. • Combination solder or quick connect terminals. • Split bobbin construction eliminates the need for an electrostatic shield. • Hi-pot tested to 2 KV RMS. • Economical open style, channel frame - chassis mount design. • Insulation material - Class B or 130C. • Lower temperature rise designed not to exceed Class A for longer life. • UL listed (#E207860) Type 3AH. • CSA certified.

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TITANIUM The new generation of wave soldering systems – lead free soldering without corrosion. TITANIUM is the innovative soldering solution developed by STRECKFUSS SYSTEMS. It uses titanium, an agent which is extremely lead free solder resistant. For this reason, titanium works perfectly in lead free soldering processes. An oxide film immediately covers all material damages and thus prevents corrosion. In contrast to wave soldering systems with stainless steel components, titanium is not subject to corrosion even when lead free solder is used. By means of a simple and safe solder bath exchange, TITANIUM makes it possible to switch flexibly from a standard soldering process to lead free production. This ensures maximum flexibility at minimum costs and easy handling. TITANIUM is a complete system and includes: Spray fluxer with extraction hood Double wave 3- D wave (for the prevention of solder bridges) Infrared preheating Microprocessor controls Soldering frame transportation system

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

SELECTIO Selective soldering systems for automatic single point soldering and multiple point soldering It is not always possible to use mass soldering processes such as wave soldering to perform a certain soldering task. Individual soldering steps are often necessary. To automate this process and to lower the costs while maintaining the high quality requirements, STRECKFUSS SYSTEMS has developed the selective soldering system SELECTIO. Just like our wave soldering system TITANIUM, SELECTIO too is equipped with the corrosion and tin resistant agent titanium and therefore works perfectly for lead free soldering. Product characteristics – an overview: x/y/z- axes system with precision toothed drive belt transport system and assembly carrier standard stand- alone- system (offline system): optional transportation belt connection as inline system printed circuit board transportation with assembly carrier soldering processes: single point nozzle and surface nozzle as well as dip soldering via mask technique fluxing out of vendor's flux container with multi- drop- fluxer nozzle short wave IR- quartz- radiators for preheating of printed circuit boards pyrometer for contact- free temperature check of printed circuit boards easily exchangeable soldering nozzles Microsoft© Windows user surface and process visualization: - BDE for documentation complying with DIN ISO 9000 ff - management data organization - optional real- time video surveillance

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

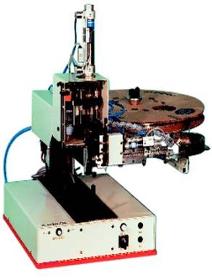

TYP A 040 Solder lug insertion device Description The solder lug insertion device Type A 040 is designed to insert pre- stored solder lugs into p. c. boards. The components are supplied automatically to the device, and will be pressed into the p. c. board by an air cylinder. Therefore, the p. c. board has to be held to the setting position manually, and a tracer finger then triggers the setting process. The inserting device will handle all usual in the trade solder lugs, which are lined up on wire or adhesive tape. Replacing the insertion head and the bin makes it possible, to process solder tags with different dimensions and forms. The re- tooling is easy, and takes only a few minutes. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

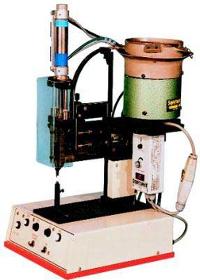

TYP A 040/B Solder lug inserting with tape feeder Description The solder lug inserting device Type A 040 B, was constructed for a mechanised insertion of solder lugs. Fixed cycles of less than one second are within easy reach. A Foot pedal controls the individual stroke sequence. The taped solder lugs are automatically fed into the machine. Therefore, no additional material and wage costs for threading the solder lugs on leads will arise. The device is able to process all kind of taped solder lugs with standard forms. After a slight alternation, solder lug strips, which deviate from standard, can also be processed. To do this, you simply have to replace the insertion head with stripe guide and the cutting tool, which is fast and easy to do. All driving elements and electrical switches belong to the main machine and therefore, they do not have to be moved. The bearing pedestal for the material bin can hold coils up to 500 mm ø. An adjustable conical ring centres the coil on the bearing pedestal. Working with this device is very easy and save. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

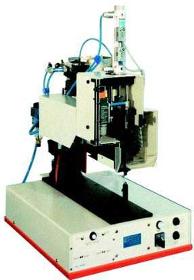

TYP A 040/R Solder lug inserter Description The Streckfuss solder lug inserting device Type A 04 R is designed, to insert solder lugs into p. c. boards. The Solder lugs are automatically moved into the device by a vibrating conveyor. An air cylinder then presses them into the p. c. board. To do this, the p. c. board is to be held manually to the setting position. The setting process by itselve is triggered over an tracer finger. This inserting device is able to process all kind of usual in the trade solder lugs (incl. double tongues), which can be supplied by a conveyor for bulk materilas. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP A 041 Solder lug inserter Description The device Type A 041 is designed, to insert stored solder lugs (solder posts) into p. c. boards, spool bodys or contact banks. The solder lugs are pressed into the p. c. boards by an Foot pedal- activated air cylinder. The p. c. board is centered by a insertion pin. The device can optionally be equipped with a light point adjustement. All usual in the trade solder lugs which are lined up on wire or adhesive tape can be processed. Retooling to different solder lug forms is possible and easy to do. The p. c. board is placed in the frame and will be adjusted. After that the p. c. board has to be shifted manually into the working area. The setting postion can be placed trough a luminous spot. The insertion itself is triggered by a Foot pedal. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP A 042 Round pin inserter Description The Streckfuss inserting device Type A 042 offers the economical solution, for the mechanised insertion of round pins, solder posts and or - lugs into p. c. boards. With this device, nearly all customer forms of round pins, solder posts / - lugs can be processed. The loose components are filled into the sorting pot of the vibration conveyor. Trough barriers in the helical of the conveyor, the components are ordered. After positioning, the components are handed to the loading slider, which supplies the components to the inserting tool. Working with this device is save and easy: For assembling, hold the p. c. board with both hands on the edges, and place it under the inserting tool. The p. c. board now lies at the bottom of the pressure stamp, while the tooling pin hole is placed directly under the solder post / - lug shaft looming out of the inserting tool. This has the function of a locating pin. The p. c. board is lifted parallel, so the components shaft enters the tooling pin hole. The insertion process is triggered by a foot switch. Components

Request for a quoteResults for

Solder - Import exportNumber of results

32 ProductsCompany type