- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machine tables

Results for

Machine tables - Import export

CUPASO DEUTSCHLAND GMBH

Germany

Due to our continuously flat sealing plate, different blister formats can be sealed. The format can be changed in just a few steps and without tools. Of course, we will provide you with the format inserts suitable for your product. On request, we can also supply you with the matching blister boxes and sealing foils.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Due to our continuously flat sealing plate, different blister formats can be sealed. The format can be changed in just a few steps and without tools. Of course, we will provide you with the format inserts suitable for your product. On request, we can also supply you with the matching blister boxes and sealing foils.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Due to the double-sided drawer, sealing and reloading can be done in one operation. The process times are freely selectable and operation is either continuous or by manual triggering by the operator. Due to our continuously flat sealing plate, different blister formats can be sealed. The format change can be done in a few steps and without tools. Of course, we will provide you with the format inserts suitable for your product. On request, we can also supply you with the matching blister boxes and sealing foils.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Due to the double-sided drawer, sealing and reloading can be done in one operation. The process times are freely selectable and operation is either continuous or by manual triggering by the operator. Due to our continuously flat sealing plate, different blister formats can be sealed. The format change can be done in a few steps and without tools. Of course, we will provide you with the format inserts suitable for your product. On request, we can also supply you with the matching blister boxes and sealing foils.

Request for a quote

NORELEM FRANCE

France

Tightening the ball-end thrust screw moves the jaw plates forwards. The workpiece is pushed against the fixed stop and simultaneously forced down onto the seating face. The seating face for the workpiece can be mounted directly on the machine table.

Request for a quote

NORELEM FRANCE

France

Grid spacing 50 ±0.02 mm. Tombstones with grid holes are used on horizontal machining centres. The alphanumerically labelled grid holes guarantee a defined assignment of clamping elements by repeat setups. The tombstones conform to machine tables for machine tools acc. to DIN 55201 and JIS 6337-1980. Please order locating pins for positioning subplates on machine tables acc. to DIN 55201 separately. Please order protection plugs to plug unused grid holes separately. Ring bolts for hoisting are supplied. Other dimensions available on request. Drawing reference: 1) grid hole 2) hole for DIN 912 cap screw (D3/D4)

Request for a quote

NORELEM FRANCE

France

Grid spacing 50 ±0.02 mm. Tombstones with grid holes are used on horizontal machining centres. The alphanumerically labelled grid holes guarantee a defined assignment of clamping elements by repeat setups. The tombstones conform to machine tables for machine tools acc. to DIN 55201 and JIS 6337-1980. Please order locating pins for positioning subplates on machine tables acc. to DIN 55201 separately. Please order protection plugs to plug unused grid holes separately. Ring bolts for hoisting are supplied. Other dimensions available on request. Drawing reference: 1) grid hole 2) hole for DIN 912 cap screw (D3/D4)

Request for a quote

NORELEM FRANCE

France

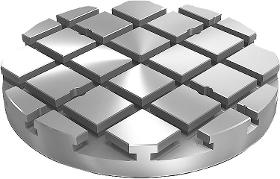

Round baseplates with T-slots are used for constructing modular fixtures. These baseplates are positioned and mounted directly on machine tables. The precise longitudinal and transverse slot spacing ensures very high repeat clamping accuracy. The aligning holes are used to align the baseplate on the machine table. Please order locating pins to locate the baseplates separately. Ring bolts with T-nuts for hoisting are supplied. Other dimensions available on request. On request: other dimensions. Drawing reference: 1) hole for DIN 912 cap screw (D4)

Request for a quote

NORELEM FRANCE

France

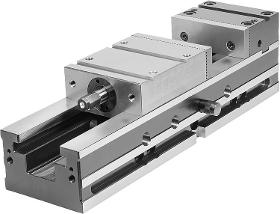

NC vices can be used for a wide range of clamping tasks: Repeat accuracy ≤0.01 mm Fixed jaw locked in all directions (X,Y,Z) Vertical use directly on the machine table Wide clamping range by using attachment step jaws Can be laid on the side, with fastening holes for slot spacing of 63 mm and 100 mm Quick pre-adjustment of the clamping range using locking pins Basic equipment includes two reversible screw-on jaws and one crank handle

Request for a quote

NORELEM FRANCE

France

These toe clamps can be used on machine tables or adapter plates. The positive down force holds the workpiece down on the supporting surface. The square washer can adapt slightly to an angular position i.e. the workpiece does not have to be exactly parallel. The clamping washer has a smooth side for machined surfaces and a serrated side for rough faces.

Request for a quote

NORELEM FRANCE

France

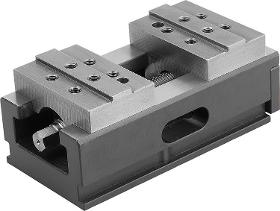

Body and jaw holder hardened and ground. Note for ordering: Supplied with hexagon crank handle. Order jaw plates separately. Note: Mechanically operated centric vice. Suitable for automation: prepared with gripper slot for handling systems. Flexible mounting: suitable for zero-point systems, mounting on machine tables or on custom systems via a baseplate. Centring precision: +/- 0.02 mm. The use of a torque wrench is recommended to achieve a controlled clamping force. Features: Clamping slide and spindle nut in one piece Slots and fastening threads for mounting attachment jaws Reversible jaws (accessories) with lateral thread for workpiece stop enables a wider clamping range Good swarf and coolant removal

Request for a quote

NORELEM FRANCE

France

The UNI lock mounting clamps can be installed in any position on machine tables, fixtures or workholding equipment (tooling plates, cubes, tombstones etc). The modular design enables the number of clamps and distance between them to be ideally adjusted to suit the clamping task. The clamps can be supplied with or without rotation lock. The high clamping forces are generated by the integrated spring package (the unit clamps when depressurised). Compressed air is applied to release the clamp. The following holding forces are possible with the UNI lock clamping bolt in conjunction with M10, M12 or M16 fastening screws: Holding force (M10) 35,000N Holding force (M12) 50,000N Holding force (M16) 75,000N Supplied with: 1x clamping module incl. 6 fastening screws. 6x screw protection caps. 2x air connection O-rings. 1x installation O-ring.

Request for a quote

NORELEM FRANCE

France

Completely mounted multi-clamping stations with integrated UNI lock Ø138 mm mounting clamps. The clamping stations are secured to the machine table directly or with clamps. Common bore patterns are pre-centred on the rear side for mounting. Clamping stations can be aligned via the 14H7 reference holes. The clamping stations are actuated via a central pneumatic connection. The high clamping forces are generated by the integrated spring package (the unit clamps in the de-pressurized state). The release process occurs pneumatically. The following retaining forces are possible with the UNI lock clamping bolt in conjunction with mounting screws M10, M12, M16: Retaining force (M10) 35,000N/module Retaining force (M12) 50,000N/module Retaining force (M16) 75,000N/module

Request for a quote

APD MAQMASTER

Spain

Fixed Bakelite work table: Robust and resistant, ideal for demanding jobs. Closed table technology: Allows both suction cup and nesting operations, optimizing your workflow. Controlled axes: Three, four or five axes for greater precision and flexibility in your projects. Suitable for any type of processing: Perfect for cutting, milling, drilling and much more. Ideal for working with panels Horizontal CNC machines with a closed table are especially recommended for those working with wooden panels, as the closed top technology allows for safe and precise clamping using suction cups or sockets.

Request for a quote

APD MAQMASTER

Spain

Vertical CNC woodworking machines with closed table. Vertical CNC machines with three, four and five controlled axes equipped with a fixed Bakelite work table. Suitable for any type of processing, recommended for those who work a lot of panels, since the closed top technology allows both suction cup and nesting operations

Request for a quote

APD MAQMASTER

Spain

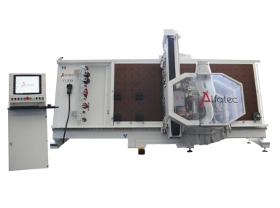

1. Advanced CNC machining center with servo turning table and 4 servo clamps. 2. Suitable for processing aluminum profiles (up to 3mm thick) and steel profiles (up to 2mm thick) with super fast speed (5m/min) and efficiency thanks to laser technology. High pressure air compressor (1.6Mpa) and cooling station are included. 3. The machine completes milling, drilling, chamfering, slotting and other multifunctional precisely in one time. 4. The work table will be positioned from +90° to -90° variable angle. 5. Automatic lifting safety cover ensures operator safety. 6. Automatic tool change: standard equipped with 6-position hidden tool magazine, standard equipped with 3 tool holders. 7. Operation in Windows environment industrial PC with monitor. Friendly machine interface with user-friendly operation. 8. In line with ERP software, it can perform code scanning and automatic processing.

Request for a quote

VIRMER

Netherlands

The Wattsan 0503 CO2 laser cutting machine is an advanced medium format model for laser cutting and engraving non-metal materials. Laser cutting machine designed for serial laser cutting and engraving, it can easily handle wood, plywood, cardboard, paper, plexiglass, acrylic, plastic, rubber, leather, fabric,s and fur. Through table: enables the laser cnc machine to work with materials of unlimited length. The design of the equipment allows you to remove the front wall and use the freed space for through cutting. Work area - 500x300 mm with a manual lifting table, which is necessary for processing bulky products up to 20cm (7.87 in) thick, makes it possible to install a rotary device. And then the CO2 laser machine is used for engraving on cylindrical surfaces. It will be convenient for you to work with different heights of the material. Work area====500 x 300 mm Tube power====60W Max engraving speed====700 mm /s Dimensions====650 mm * 1040 mm * 575 mm Net Weight====104kg

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VIRMER

Netherlands

CNC milling and engraving machine WATTSAN A1 1616 is a cost efficient, easy-to-use and multi-purpose equipment. The machine performs a cutting and engraving, also WATTSAN A1 1616 can perform a 3D milling. WATTSAN A1 1616 has working area of 1600×1600×200 mm, spindle ER-25 with power of 2.2 kW, water cooling system. The portal is moved by step engine controlled by driver Yako 2405. Operator controls the machine with control system NC-Studio. Frame of the machine is welded from steel profiles construction; weight of the machine is 500kg. Max speed of spindle movement along axis is up to 25 000 mm/min, max working speed is 15 000 mm/min. Spindle rotation speed can reach 24 000 rpm. The working table has a T-slot grid plate. We can modernize the machine with the following: vacuum table, DSP controller, chip removal system, automatic lubrication, more powerful spindle or additional cutting heads, rotator for cylinder shaped parts, tool sensor.

Request for a quote

VIRMER

Netherlands

WATTSAN M1 2030 wide-format machine has a large working area of 2000×3000 mm with a slatted table top. The design includes a spindle with an ER-25 collet chuck and a power of 6 kW. An air cooling system and a built-in vacuum cleaner for collecting wood chips and dust are also available for an additional fee. The leadshine 860 stepper motor driver is responsible for moving the portal, the machine is controlled by the operator through NcStudio. The body of the machine is a welded structure made of steel profile, the weight of the machine is 1400 kg. The maximum travel speed along the axes is 25 000 mm/min, the maximum travel speed during operation is 15 000 mm/min. The spindle speed reaches 24 000 rpm. If you want a more upgraded machine, we can install: Vacuum table. DSP controller. Syntec control system. chip removal system. manual auto lubrication. more powerful spindle or additional cutting heads. rotary device for processing cylindrical products. tool sensor.

Request for a quote

VIRMER

Netherlands

WATTSAN 1325 BASIC fiber laser machine is an economical and practical machine for cutting thin sheet metal. The metal cutting machine works with stainless and carbon steel, copper, aluminum, titanium and other materials. This machine is often purchased for manufacture, such as aviation, astronautics and mechanical engineering. We can install Maxphotonics / Raycus / IPG fiber laser emitter for choice. The main advantage of a fiber laser over a gas laser is its high speed and accuracy of operation, as well as durability: the life of the ignition unit is 100,000 hours, i.e. years of continuous operation. The machine has a working table 1300x2500 mm. WATTSAN 1325 BASIC laser machine is a high-precision device with a reliable control system. It has a high-quality fiber laser emitter. Of course, such a device will last a long time, because the declared service life of the frame is 20 years.

Request for a quote

VIRMER

Netherlands

CNC milling and engraving machine WATTSAN A1 1325 is a multi-purpose equipment for engraving, cutting and 3D milling sheets of materials. WATTSAN A1 1325 has a grid type working table of 1300×2500×200 mm, but additionally we can install a vacuum table, that holds the sheet material in place and significantly ease the process. A spindle ER-25 with collet has power of 3 kW, water cooling system. The portal moved by step engine controlled by driver Yako 2405. Frame of the machine is welded from steel profiles construction; weight of the machine is 800 kg. Max speed of movement along axis is up to 25 000 mm/min, max working speed is 15 000 mm/min. Spindle rotation speed can reach 24 000 rpm. The machine controlled by NC-Studio control system. We can modernize the machine with the following: vacuum table, DSP controller, Syntec control system; chip removal system, automatic lubrication, more powerful spindle or additional cutting heads, rotator for cylinder shaped parts, tool sensor.

Request for a quote

VIRMER

Netherlands

CNC milling and engraving machine WATTSAN М1 1616 belongs to М1 series, that is considered more technically sophisticated than A1 series and has a massive frame. The frame is more stable and allows process more complex parts. The machine is applicable for cutting of wood, MDF, chipboard, acryl, plexiglas, PVC, aluminum, composite. Using WATTSAN М1 1616 you can also perform a 3D milling. WATTSAN М1 1616 has a grid type working table of 1600×1600×300 mm, but additionally we can install a vacuum table, that holds the sheet material in place and significantly ease the process. Max speed of movement along axis is up to 25 000 mm/min, max working speed is 15 000 mm/min. Spindle rotation speed can reach 18 000 rpm. The machine controlled by NC-Studio control system. We can modernize the machine with the following: vacuum table, DSP controller, chip removal system, automatic lubrication, more powerful spindle or additional cutting heads, rotator for cylinder shaped parts, tool sensor.

Request for a quote

VIRMER

Netherlands

WATTSAN М1 1313 has a grid type working table of 1300×1300×200 mm, but additionally we can install a vacuum table, that holds the sheet material in place and significantly ease the process. The construction includes a spindle ER-25 with collet and power of 2.2 kW, water cooling system. The portal moved by step engine driver Leadshine 860. Operator controls the machine with control system NC-Studio. Frame of the machine is welded from steel profiles construction; weight of the machine is 700kg. Max speed of spindle movement along axis is up to 25 000mm/min, max working speed is 15 000mm/min. Spindle rotation speed can reach 24 000 rpm. We can modernize the machine with the following: vacuum table, DSP controller, chip removal system, automatic lubrication, more powerful spindle or additional cutting heads, rotator for cylinder shaped parts, tool sensor.

Request for a quote

VIRMER

Netherlands

WATTSAN A1 1313 machine has a working field of 1300×1300×200 mm, an ER-20 spindle with a power of 2.2 kW, and a water cooling system. A stepper motor controlled by the Yako 2405 driver is responsible for moving the portal. The body of the machine is a welded structure made of steel profile, the weight of the machine is 500 kg. The maximum travel speed along the axes is 25,000 mm/min, the maximum speed in operation is 15 000 mm/min. Spindle speed can reach 24000 rpm. The table has a slatted T-slot cover. The machine is controlled by NcStudio software. To upgrade this machine, we can install: vacuum table. DSP controller. Chip removal system. Manual auto lubrication. More powerful spindle or additional cutting heads. Rotary device for processing cylindrical products. Tool sensor.

Request for a quote

GLOMACHT BV

Netherlands

Willing to sell or buy used or new industrial machinery? Share your power and let GLOMACHT get in charge of everything.CNC Machining centers - Year: 2011 CNC controlled gantry milling machine with flat table and drill unit.

Request for a quote

FRIMO GROUP GMBH

Germany

A concept for higher productivity FRIMO VarioForm inline and rotary table thermoforming machines are primarily used in the automotive industry and are ideally suited for forming a wide range of films and sheet materials.

Request for a quote

FRIMO GROUP GMBH

Germany

A concept for higher productivity FRIMO VarioForm inline and rotary table thermoforming machines are primarily used in the automotive industry and are ideally suited for forming a wide range of films and sheet materials.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Uses the HSK-A type, time-proven tool holder shank to connect the head and the work-piece holder. Off-line setup in advance allows quick work-piece changing, minimizing machine downtime. Accepts a variety of workholders Excellent workpiece accessibility In the case where you can’t mount the head directly to your machine table, please use this mounting plate. We can supply a blank that is customisable and also manufacture a special mounting plate just for you. For more information, please feel free to contact us.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Compact Design Triple disc brake system for high clamping force High speed and accuracy Rotary joint as an option MR series Rotary Table with compact design and high accuracy. The innovative triple disc brake system gives substantially increased clamping force. Available with all motor types in right or left hand configurations to suit a variety of machine models. Price for tables numbered MR*** includes Rotary Table, Motor to suit (Fanuc, Mitsubishi or Yaskawa) and cables (internal and external). RAV specification comes with an external controller that functions off a spare M-Code; used for machines that do not have 4th axis preperation. **Drawings and models subject to machined control**

Request for a quoteResults for

Machine tables - Import exportNumber of results

36 ProductsCompany type

Category

- Milling - machine tools (6)

- Clamp collars, plastic (6)

- Custom packaging (4)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (3)

- Hydraulic equipment (3)

- Steel, special (3)

- Laser apparatus and instruments (2)

- Laser - cutting and welding machines (1)

- Cars - electrical and electronic parts and components (1)

- Steels and metals - forming and cutting (1)