- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- insulator manufacturing

Results for

Insulator manufacturing - Import export

REP INTERNATIONAL

France

Designed for the manufacture of highvoltage insulators (550 kV), this press is one of the largest presses made by REP. The dimensions of the parts to be injected explain the huge size of the press 660 mm in diameter, 2,600 mm long, moulded in one go. The production of a complete insulator is therefore performed in one or two cycles, thus significantly increasing the profitability and reliability of the parts. Machine features Closing force 24,000 kN Size of the platens 1,500 x 3,000 mm Injection volume 25,000 cm³ x 2 (2 injection units)

Request for a quote

FRIMO GROUP GMBH

Germany

Processing sound-absorbing materials such as textiles, carpets or foamed materials requires efficient and high quality system technology. FRIMO supplies tailor-made solutions for insulation and acoustic component manufacturing for vehicles or other applications which require noise-cancellation.

Request for a quote

KGA ENCLOSURES LTD

United Kingdom

Product Features: • Designed for push-pull tube output circuits. • Enclosed (shielded), 4 slot, above chassis Type "X" mounting. • Frequency response 30 Hz. to 30 Khz. at full rated power (+/- 1 db max. - ref. 1 Khz.) minimum. • Insulated flexible leads 8" min. • Manufactured with plastic coil forms for coil support and insulation. • Typical applications - Push-Pull: triode, Ultra-Linear pentode, pentode and tetrode connected audio output. • Due to the unique interleaving of the windings BOTH secondary windings must be engaged to meet specifications.

Request for a quote

KGA ENCLOSURES LTD

United Kingdom

Product Features: • Designed for push-pull tube output circuits. • Enclosed (shielded), 4 slot, above chassis Type "X" mounting. • Frequency response 30 Hz. to 30 Khz. at full rated power (+/- 1 db max. - ref. 1 Khz.) minimum. • Insulated flexible leads 8" min. • Manufactured with plastic coil forms for coil support and insulation. • Typical applications - Push-Pull: triode, Ultra-Linear pentode, pentode and tetrode connected audio output. • Due to the unique interleaving of the windings BOTH secondary windings must be engaged to meet specifications.

Request for a quote

PANEL SELL GMBH

Germany

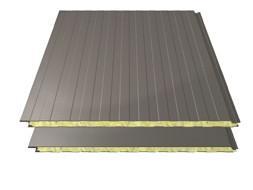

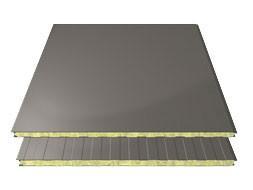

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PANEL SELL GMBH

Germany

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quote

PANEL SELL GMBH

Germany

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quote

JC CATERING & BAR SUPPLIES LTD

United Kingdom

Hot drink board cups with attached insulating jackets for handling comfort and insulation. Manufactured from premium food grade cup stock, single poly-coated 12oz Double Wall/Triple Layer Kraft Ripple Wrap Paper Cups in plain brown. Takeaway cups that are made for the Coffee to go market. Lids bought separately.

Request for a quoteResults for

Insulator manufacturing - Import exportNumber of results

9 ProductsCountries

Company type