- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- forming machines

Results for

Forming machines - Import export

TECHNIC MACHINES

Turkey

As Technic Machines, we supply all kind of roll forming machines. We have in our portfolio some standard roll former machine lines but also we provide customs solutions for our customers Roll former machine is pretty common machine in metal industry and each work can have small differences because of the local market demand on roll forming shape. We provide exact solution for our customers with different width, thicknesses and shapes of roll forming. We supply for our customers as standard roll form machine, Customs Roll Former Machine Glazed and Step Tile Making Machine Roof Panel Roll Forming Machine Trapezoidal Sheet Roll Forming Machine Corrugated Sheet Roll Forming Machine Rolling Shutter Roll Former Machine Drywall and Gypsum Channel Making Machine Just contact with us for your other roll forming machine request, we will provide customs solution according to your roll former machine research.

Request for a quote

TECHNIC MACHINES

Turkey

Complete turnkey roll forming machine line according to the finished final product with all necessary equipment, such as uncoiler, feeder, roll former, hydraulic or eccentric presses, stacking unit, etc. We offer standard models of roll forming machines as well as specific models according to the final product requirements of our customers. Some of our standard roll forming machine models are: • Warehouse racks and shelves • Market racks and shelves • Building and construction • C, U, Z, and Sigma (track and stud) • Guardrail • Roll-up door forming machine • Roof panel forming machine • Standing seam • Wall panel • Drywall and plasterboard • Snap lock • Cable tray • Scaffolding Just contact us for any roll forming machine you need, and we will find the optimal solution.

Request for a quote

TECHNIC MACHINES

Turkey

Rolling Shutter Forming Machine is for manufacturing the roller shutters with different width, thickness and roller shutter forming according to customer’s request. Rolling shutter raw material can be strong steel or such as aluminium as to final customers. The main using area of roller shutters are shops, houses industrial constructions, super markets and other constructions. Design and widths can be change of shutter door forming, also sheet metal thickness can be different according to market target price demand or safety requirements. We design for different thickness and working range of our roller shutter door roll forming machine, also general working width of rolling shutter roll forming will be between 80 to 130 mm, but it can be different according to local markets. Roller Shutter Door Roll Forming Machine Units Coil Decoiler Rolling Shutter Door Forming Unit Roller Shutter Door Punching Unit Rolling Shutter Door Fly Cutting Unit Shutter Stacking Unit

Request for a quote

TECHNIC MACHINES

Turkey

Roof panel roll former machine is pretty common almost all countries. Shape of metal roof panel can be different by countries but we provide also different shapes for our customers. Also we can provide different cassette or double layer on our roof panel machine. Roof Panel Roll Forming Machine's Units - Coil Decoiler Machine - Roll Forming Unit - Cutting Shear - Control Panel - Stacking Unit Just contact with us for your request, we will provide the optimum solutions.

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

Applications and projects : conveyor systems assembly lines robotic units screwing welding Poka-Yoke vision Pick and Place Some practical examples : roll-forming machine conveyor system with elevator assembly lines for plastic and metal components ergonomic workstation on assembly line unit for recovery, transfer and removal of springs on assembly line

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NORELEM FRANCE

France

1.4401 stainless steel, similar to DIN 39. Grip suitable for DIN 950 handwheels.

Request for a quote

SYSKOMP GMBH - EMICO

Germany

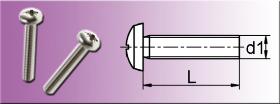

Lens head screws - metal, cross slot ~DIN 7985 (~DIN EN ISO 7045 - form H) Material: machining steel 4.8 zinc-plated

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 069 Cutting, stamping and bending device for radial components The Cutting and Forming Machine for horizontal & vertical Mounting and tube to tube feeding. The cutting and forming machine Type C 069 is designed to cut and form components with 3 up to 23 leads for vertical or horizontal mounting. The feed magazines and die sets are modular in design to allow quick set up changes. All cutting and forming parameters are manufactured to customer specification. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP A 075/Ri Forming Machine for DIP Components Description The Streckfuss forming machine type A 075 Ri is designed to form the leads of dual in- line package components utilizing a tube- to- tube feeding configuration. The machine is able to process DIP's in a wide range of component sizes (from 7,62 mm up to 19,9 mm). The adjustment of lead span can be preset and is displayed on a digital panel. The supply of components can only be done by the use of component tubes. The processing speed is continuously variable. Up to 5.000 components can be processed within an hour. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP A 075 Cutting & Forming Machine for DIP Components Description The Streckfuss cutting and forming machine type A 075 is designed to cut and form the leads of dual in- line package components utilizing a tube- to- tube feeding configuration. The machine is able to process DIP's in a wide range of component sizes (from 7,62 mm up to 19,9 mm). The component leads are first formed to the desired lead span and then cutted to desirable length. The adjustment of lead span and cutting parameters can be preset and are displayed on a digital panel. The supply of components can only be done by the use of component tubes. An empty component tube picks up the processed components. The processing speed is infinitely variable. Up to 3.500 components can be processed within an hour. Components

Request for a quoteResults for

Forming machines - Import exportNumber of results

11 ProductsCountries

Company type