- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- clamping jaws

Results for

Clamping jaws - Import export

NORELEM FRANCE

France

The functioning principle make the wedge clamps ideal for series clamping. The wedge form can exert high clamping forces. These wedge clamps can be mounted in grid holes or T-slots. Tightening the socket screw moves the wedge down and the jaws out pressing the workpieces against the fixtures fixed stops. The wedge has a slightly elongated hole allowing for movement to compensate for tolerances. Spread width: M8 = ±0.5 mm M10 = ±1.0 mm M12 = ±1.0 mm M16 = ±1.5 mm Drawing reference: D) DIN 6912 cap screw 1) Jaw face smooth 2) Jaw face serrated 3) Wedge clamps 4) Workpiece 5) Fixed stop

Request for a quote

NORELEM FRANCE

France

Fasten the floating clamp to the fixture with the M12 screw. Adjust the height stop and the swivel range using the blue sleeve and lock with the 3x2.5 mm grub screws. When setting the height leave generous clearance above. For safe operation the M12 tapped hole must always be closed. For specific clamping applications the standard jaws can be altered or replaced. Form B: Fasten the floating clamp with M6 fastening holes to a fixture. Adjust the height stop and pivot range using the blue adjusting sleeve and clamp with grub screws (4x AF 2.5). When setting the height limit, allow ample play at the top. For specific clamping situations, the standard jaw plates can be modified or replaced.

Request for a quote

NORELEM FRANCE

France

The pneumatic hold-down clamp is suitable for clamping workpieces from above. This clamp is operated with standard pressure compressed air. The large swivel angle of the clamping arm makes it easy to insert and remove the workpieces without any obstructions, guaranteeing optimum accessibility to the workpiece. The block design of the housing offers universal fastening possibilities, which means that the clamp can be optimally adapted to the workpiece being clamped. Self-aligning pads with a smooth or serrated faces can be fitted in the clamping arm, enabling rough or machined workpieces to be clamped. These pneumatic clamps can be placed in multiple positions on the workpiece and operated in any particular order. They can be controlled manually or automatically. As these clamps are pneumatically actuated, they relieve the operator, particularly where frequent clamping processes are carried out.

Request for a quote

NORELEM FRANCE

France

Housing and arm carbon steel. Jaw tool steel. Version: Housing, black oxidised. Arm and jaw tempered and black oxidised.

Request for a quote

NORELEM FRANCE

France

Tightening the ball-end thrust screw moves the jaw plates forwards. The workpiece is pushed against the fixed stop and simultaneously forced down onto the seating face. The seating face for the workpiece can be mounted directly on the machine table.

Request for a quote

NORELEM FRANCE

France

We recommend using a lubricating paste to reduce wear to the adjustment screw. Risers are available to increase the height of the power clamp. Supplied with clamping element, support element, DIN 508 slot key and grade 12.9 bolt. Application: The height of the clamping arm can be infinitely adjusted using the adjustment screw and the workpiece can then be clamped. Advantages: Very high retaining forces of 22–49 kN. Low height. Simple element assembly. Enables very fast, simple clamping. Infinitely adjustable height and length. Use in 12-28 mm T-slots or M10, M12, M16, M20 grid systems. Thrust pad available in smooth and serrated versions.

Request for a quote

NORELEM FRANCE

France

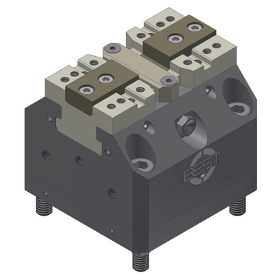

The easy operability and rapid adjustment using a scale means that the clamping jaws can be quickly and surely adapted to new workpieces The workpiece is always centred through the systematic construction of the 5-axis compact clamping system. The optimal accessibility to the workpiece allows short, standard tooling to be used. Tooling costs are significantly reduced. Positive down force by a clamping depth of >5 mm. Clamping widths of 20 mm to 320 mm are possible. Assembly: The 5-axis clamping system compact can be mounted on T-slot tables, grid systems or, using an adapter flange on conventional zero-point clamping systems. Accessory: Seating ledge 41345 Jaw plates 41320 Pendulum jaws 41325 Centre jaws 41335 Coupling for cross-clamping 41365 Order the seating ledges and jaw plates with pins separately.

Request for a quote

NORELEM FRANCE

France

The lateral clamping screw tightens the jaws and clamps the workpiece on the circumference. The simple and compact design allows 2 workpieces to be clamped. The clamping travel is max. 0.5 mm. The jaws must be pre-tensioned before machining the contour, the supplied clamping ring is used for this purpose.

Request for a quote

NORELEM FRANCE

France

Grippers and inserts are ideal for use in clamping arms, gripping systems, clamping fixtures, clamping jaws and self-aligning pads. The use of grippers allows the transfer of very high torque values and above average grip, even with hard materials and surface irregularities. Form O: The abrasive diamond surface is bonded firmly to the base. It is ideally suited to supporting smooth or slippery applications with a minimum of clamping pressure. This allows the diamond particles to get a firm grip on a very small area with minimum damage to the surface. The diamond surface offers excellent wear resistance. Form P: The polyurethane surface is vulcanised firmly to the ball. It is abrasion-resistant and does not discolour. It offers optimum protection against damage to delicate surfaces. The pearl-like surface gives a firm grip and allows air to escape so as to prevent any suction effect between the contact surface and the self-aligning pads.

Request for a quote

HONSEL-GROUP

Germany

Reliable with low wear. On the HONSEL BZ 143A, the clamping jaws are specially adapted to the trapezoidal grooves of the rivet mandrel. In combination with the modified clamping mechanism, this guarantees secure and positive setting of FERO® BULB high-strength blind rivets (or comparable types) with mandrel diameters from 3.8 to 6.15/6.5 mm! Wear of the clamping jaws is minimised!

Request for a quote

HONSEL-GROUP

Germany

Reliable with low wear. On the HONSEL BZ 143A, the clamping jaws are specially adapted to the trapezoidal grooves of the rivet mandrel. In combination with the modified clamping mechanism, this guarantees secure and positive setting of FERO® BULB high-strength blind rivets (or comparable types) with mandrel diameters from 3.8 to 6.15/6.5 mm! Wear of the clamping jaws is minimised!

Request for a quote

HONSEL-GROUP

Germany

The HONSEL Rivdom eBZ 3 battery riveter was developed specially for the demands of the setting of high-strength blind rivets with 6.4 and 7.8 mm diameter with grooved rivet stud! The clamping jaws specially designed for this geometry and a modified clamping mechanism guarantee reliable and positive settings of high-strength blind rivets with a stud diameter from 3.8 to 6.15 mm. This also helps to minimise wear on the clamping jaws. Rivdom eBZ 3 has a modern brushless DC (BLDC) motor. Ergonomy and comfort: Quick-release mechanism: No more than one open-jaw wrench for maintenance! Individual return mode setting: When using manual return mode, the trigger has to remain pressed until the rivet is sheared. When the trigger is released, the tool moves back to the front starting position. In addition Rivdom eBZ tools offer an automatic return mode. L-Boxx: Sturdy and flexible. High-quality RivdomPLUS battery system Extended 24-month manufacturer's warranty.

Request for a quote

APD MAQMASTER

Spain

FEATURES Aluminium table with special alloy, steel sheet bed, resistant and durable electrostatic paint. Disc protection. Manual cutting and feed system. Left to right cutting characteristic at standard degrees: 15º – 22.5º – 30º – 45º – 90º and free cutting at various angles. Band cabin to isolate vibrations. Pneumatic clamping jaws. Automatic lubrication system. Disc Ø 400 mm. Service key Lubrication system

Request for a quote

PROSAW LIMITED

United Kingdom

Heavy Duty Automatic Bandsaw for solid bar, bundles & general sawing with the following features: Vice feed automatic with encoder for precision length set Twin hydraulic vices clamp both sides of material Simple input of component length and number of pieces via touch screen Steplessly variable blade speed 17 ~ 67m/mm Hydraulic blade tension control for optimum blade life. Variable downfeed control. The touch sensitive control screen provides easy selection of precise bar length requirement for a precise cut off length. The auto head-elevation reduces index cycling time significantly. The Blade speed is set and adjusted by acting on the touch sensitive control screen. There are quick-adjusting carbide saw-band guides, there is an idle wheel motion protector, a hydraulic band tension control, a quick-action HYDRAULIC twin-vice (split vice) 3-jaw clamping, a unique two-way vice jaw and an automatic chip conveyor.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Change jaws in seconds and complete a full setup in a few minutes Precise loction of jaws means your datum is preserved every time you remove the jaws. Once a job is setup, it stays setup. Two parts in the same space as one. Maximise your working area and optimise the toolpath. Machinable workholding means complex shaped workpieces are easy to grip Fully machinable aluminium jaws for use on either 0520 Qwik-Loks or 0520 Multi-Loks. The Dual Station Machinable Jaw Sets clamp with an equal and opposing inward force, thus eliminating the potential for jaw lift. The safe low profile jaw interface maximizes the amount of machinable area, giving the ability to hold larger parts. These jaw sets are available in standard size or oversize. An additional set of jaws can be created by purchasing an additional fixed jaw and reversing the movable jaws. All jaws are available as sets or individually.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Quick change jaws for fast setups Hardened and precision ground for wear resistance and accuracy Ideal for demanding clamping conditions and high clamping forces Plain hard jaws for OneLok that fits 5OL1540 and 5OL1550 and well as the previous generation of OneLok. These jaws are hardened and precision ground for strength and accuracy. The BoltFast mechanism means they can be changed in seconds.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

2+2 Independent jaws give contact with all four jaws Long stroke grip compounets with variable size Ideal for square or elliptical parts Compatible with large, readily available, range of jaws Kitagawa chucks are manufactured from high grade alloy steel. The Kitagawa HW series are four jaw chucks but unlike conventional four jaws it works off a 2+2 system clamping two jaws indapendently garentees gripping with all four jaws unlike standard chucks. HW series chucks are supplied with blank drawnut and a set of t-nuts as standard.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Repetition Accuracy of 5 micron Extremely High Clamp Forces Low wear due to Nitrogen Hardened Surfaces Suitable for Internal or External Clamping BEST hydraulic centric vices are a no compromise solution to repeating and long running 4th and 5th axis workholding. BEST have focused on the production of high accuracy, high rigidity vices. These vices are suitable for both internal and external clamping. They offer very high clamping forces and repeatability of 0.005mm and a centring accuracy of 0.01mm. The Hydraulic vices also have the following options: Clamp Path Monitoring, Fixed Jaw, Central Lubrication System and Positive Air Pressure to prevent swarf ingress.

Request for a quoteResults for

Clamping jaws - Import exportNumber of results

19 ProductsCountries

Company type