- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- be tools

Results for

Be tools - Import export

THOMSON MACHINERY BV

Netherlands

Jung JF520 surface and profile grinding machine in very good condition. Machine No. 1569. Year of construction 1981 - Grinding length max. 600 mm - Sliding width: 200mm - Magnet size: 500x175mm - Grinding wheel dimensions: 250x25x50.8mm Bcspaqsayd8 - Spindle speed: stepless 4200 omw./min. - 380V 4kW - Weight about 2000kg Equipment: - 1 axis digital display, - Flanges - Infinitely adjustable spindle speed - Infinitely variable hydraulic supply in transverse direction - auto lubrication system, - Automatic height feed with rapid traverse - machine books

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Yokota system e-wrenches have a built-in torque transducer and angle-encoder on the main shaft and is wireless connected to a controller. The Yokota battery system e-wrench is the perfect solution for applications where cables or hoses are disruptive, but you still need to have all data checked, controlled and documented. Wireless communication with the control unit WU-1 for up to 10 meters. Each controller can be paired with up to 4 independently operating battery system e-wrenches. For data-collection, the controller is equipped with a RJ-45 connector for LAN Ethernet TCP/IP. Optional Display DC-2 shows tightening result (OK / NG and torque level reached) and either the free running angle, the tightening angle or the number of bolts and number of impulses. Connection to the WU-1 controller by means of cable with 5 meter length (included in delivery). [...]

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

The Yokota YZ-T cordless impulse wrench is detecting the amplitude of the tightening force from motor loaded condition. Based on the programmed values, the YZ-T wrench makes self-shut-off intelligently. As a result, the YZ-T achieves highest torque accuracy and safety against misconnections. An integrated status LED is visible virtually all around. The YZ-T series provides a rugged impact-resistant housing. Its pulse cell works without a mechanical shut-off mechanism and is easy to maintain. The optimized design allows extended maintenance intervals. The grip fits well in the hand and the tool is perfectly balanced. Intelligent Shut-Off. The combination of the adjustment of the pressure relief valve and the speed setting of the motor allows an optimal adaptation to the respective bolt joint to be connected. Thus the electronically controlled shut-off effects precisely and stable according to the entered parameters for smallest torque tolerances. [...]

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Electric Impulse Tool with Torque Control and Angle Monitoring. The YOKOTA electric system wrenches with integrated torque transducer and angle sensor offer a large reduction of energy consumption, a high degree of accuracy and fantastic work efficiency. Faulty tightening detection with maximum accuracy due to the use of an integrated torque transducer and also an integrated angle sensor. Torque transducer and angle sensor located directly at the front of the main shaft, giving the best accuracy of measurement. The angle sensor is an extremely compact (PAT) rotary encoder that detects both angle as well as direction by 1 degree, signal transmission contactless. Due to the newly developed outer rotor servo motor and the composite body, the Yokota system e-wrench has the lightest weight in its class. For cooling of the motor it is equipped with a fan that reduces motor size (and weight at the same time). For cooling of the impulse unit it is equipped with a separate fan. [...

Request for a quote

HONSEL-GROUP

Germany

Electric-hydraulic setting tool for stationary automated or hand-held processing of blind rivet nuts and studs. Perfect combination of high setting force, slim design and low weight. The narrow design allows a small centre distance for modular design. — Process monitoring DMSD 2G Displacement encoder with resolution 0.01 mm Sensor technology force measurement via hydraulic pressure — Hydraulic connection for pressure intensifier — Mechanical connection — Tolerance compensation Position offset 1.5 mm Angular misalignment 8° — Electric motor Monitoring of torque and rotationangle during spindle mounting and dismounting — Hydraulic hollow piston cylinder stroke 12 mm setting force up to 58 kN — Quick-change system For fast handling and low-maintenance operation Low tool costs by using DIN screws as mandrel (option)

Request for a quote

HONSEL-GROUP

Germany

RivdomONE continues to impress. Indispensable for the work of many users today, the RivdomONE is equipped with many of the features of the HONSEL eBZ family, such as high-quality Li ion rechargeable batteries with RivdomPLUS charging technology, the flexible L-Boxx system and a powerful motor. The outstanding ergonomics and an extremely short trigger stroke allow quick and comfortable working. Familiar practical details such as the transparent mandrel collector, LED lighting of the riveting location or the new belt clip for mobile use round out the convincing impression of the new RivdomONE. Ergonomy and comfort: Quick-release mechanism - no more than one open-jaw wrench for maintenance! Extended warranty: We are convinced of the quality of our HONSEL battery riveters. That is why we grant a 24-month manufacturer's warranty on all current models.

Request for a quote

HONSEL-GROUP

Germany

The HONSEL Rivdom eBZ 3 battery riveter was developed specially for the demands of the setting of high-strength blind rivets with 6.4 and 7.8 mm diameter with grooved rivet stud! The clamping jaws specially designed for this geometry and a modified clamping mechanism guarantee reliable and positive settings of high-strength blind rivets with a stud diameter from 3.8 to 6.15 mm. This also helps to minimise wear on the clamping jaws. Rivdom eBZ 3 has a modern brushless DC (BLDC) motor. Ergonomy and comfort: Quick-release mechanism: No more than one open-jaw wrench for maintenance! Individual return mode setting: When using manual return mode, the trigger has to remain pressed until the rivet is sheared. When the trigger is released, the tool moves back to the front starting position. In addition Rivdom eBZ tools offer an automatic return mode. L-Boxx: Sturdy and flexible. High-quality RivdomPLUS battery system Extended 24-month manufacturer's warranty.

Request for a quote

HONSEL-GROUP

Germany

Small. Light. Smart. Industry 4.0 ready! With RivSmart you can now take the first step towards blind rivet processing of tomorrow – on the basis of decades of experience in the development of high-quality riveting tools and customised riveting automation technology. RivSmart can be easily integrated into our production processes, and with its documentation capabilities helps to optimise optimise and monitor production. Compact dimensions: Thanks to the removable transparent collecting bin, the tool can be further shortened for unrivalled ease of handling for even the most confined installation points. Weight only 1.3 kg. Documented process monitoring: RivSmart is equipped with the DMSD-lite process monitoring system. Serious errors can already be detected here and the number of set fasteners counted. Intelligent controller: In addition to its outstanding riveting properties, the RivSmart eBZ ZERO S is prepared for integration into an increasingly networked production environment.

Request for a quote

HONSEL-GROUP

Germany

The power pack. For blind rivets up to 6.4 mm. The setting force of 20,000 N and the very large stroke of 30 mm enables not only standard blind rivets but also high-strength versions such as HONSEL FERO® Bulb and FERO® Bolt (or comparable products) and folding blind rivets up to 6.4 mm diameter to be quickly and reliably set in one step. Uncompromisingly powerful. Rivdom eBZ 2 has a modern brushless DC (BLDC) motor. Ergonomy and comfort: Quick-release mechanism: No more than one open-jaw wrench for maintenance! Individual return mode setting When using manual return mode, the trigger has to remain pressed until the rivet is sheared. When the trigger is released, the tool moves back to the front starting position. In addition Rivdom eBZ tools offer an automatic return mode. L-Boxx: Sturdy and flexible. High-quality RivdomPLUS battery system Extended 24-month manufacturer's warranty.

Request for a quote

HONSEL-GROUP

Germany

Extremely lightweight. ultra compact. Optimised and specially designed for the world’s most widely used blind rivet sizes up to 4.0 mm diameter. In focus. Maximum weight reduction and compact dimensions. The outstanding ergonomics and unrivalled light weight of only 1.3 kg guarantee the highest level of comfort! — Rivdom eBZ ZERO has a modern brushless DC (BLDC) motor. Ergonomy and comfort: Quick-release mechanism: No more than one open-jaw wrench for maintenance! Individual return mode setting: When using manual return mode, the trigger has to remain pressed until the rivet is sheared. When the trigger is released, the tool moves back to the front starting position. In addition Rivdom eBZ tools offer an automatic return mode. L-Boxx: Sturdy and flexible. High-quality RivdomPLUS battery system Extended 24-month manufacturer's warranty.

Request for a quote

HONSEL-GROUP

Germany

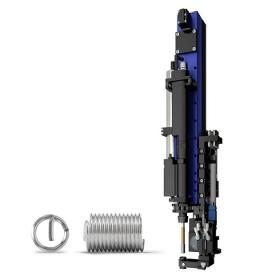

Coil screw system 2G for automated and partially automated installation of wire thread inserts. Due to the slim construction, screw systems can be placed close to each other. This leads to more efficient use of existing production areas and thus to greater economic efficiency in production. The electric linear motor is very fast at up to 3.2 m/s and enables cycle times in production to be optimized. — Screwdriver Bosch BG2 — Floating screwdriver bearings — Integrated coil transfer with rotary gripper — Linear motor — Camera

Request for a quote

APD MAQMASTER

Spain

The Galaxy IV copy router is specially designed for aluminum and PVC carpentry. 3-head copy router that allows you to attack the profile at its top, front and back without having to move the profile at any time. It has 2 easily replaceable copy templates, as well as vertical and horizontal clamps.

Request for a quote

KRAFFTER MACHINE TOOLS

France

TECHNICAL CHARACTERISTICS : Year of manufacturing :2016 CNC control: FANUC 31i Software installed: Quinto 5.4.6 Number of axes: 5 Stroke X axis: 470 [mm] Max. Stroke speed X axis: 20000 [mm/min] Stroke Y axis: 390 [mm] Max. Stroke speed Y axis: 20000 [mm/min] Stroke Z axis: 325 [mm] Max. Stroke speed Z axis: 10000 [mm/min] Table length: 1000 [mm] Table width: 275 [mm] Grinding wheel speed: 12000 [rpm] Grinding spindle motor power: 10 [kW] Internal workpiece spindle nose: HSK 50 Dimension:s 2600 x 3500 x 2600 [mm] Weight: 4700 [Kg] Machine visible under power in our premises by appointment. Price on request, loading on truck included. Possibility of shipping Worldwide.

Request for a quote

KRAFFTER MACHINE TOOLS

France

Year of manufacturing:2014 CNC control:FANUC 31i - MODEL B Centre distance:1200 mm Height of centers:230 mm Max. grinding diameter:455 mm Max. grinding length:1140 mm Stroke X axis:400 mm Max. Stroke speed X axis:12000 mm/min Resolution X axis:0.0001 mm Stroke Z axis:1330 mm Max. Stroke speed Z axis:12000 mm/min Resolution Z axis:0.0001 mm Orientation of table:0 / 9 ° Grinding spindle motor power:8.5 kW B axis swivelling stroke:-15 / +195 ° B axis indexing precision:0.001 ° Automatic B axis:Yes Max. diameter grinding wheel:508 mm Max. grinding wheel width:80 mm Grinding wheel bore:203.2 mm Workpiece spindle nose:ASA 5 Internal workpiece spindle nose:Morse 5 Workpiece spindle min. speed:10 rpm Workpiece spindle max. speed:700 rpm Workpiece swiveling range:+/- 10 ° Type of attachment tailstock:Morse 4 Tailstock quill stroke:40 mm Tailstock quill diameter:60 mm Tailstock fine adjustment:+/- 100 μm Max.

Request for a quote

KRAFFTER MACHINE TOOLS

France

Pallet loading automation unit 4 stations 1 pallet included Technical documentation included

Request for a quote

KRAFFTER MACHINE TOOLS

France

x1 infeed Z-axis: Infeed operation, metric 4 E-M with position reading - ref: 111-2-10666 x1 cross feed X-axis Fine cross feed 4 FQ-M - ref: 111-2-21708 x1 grinding stroke 3H: operation of the grinding stroke either by lever or by hand wheel - ref: 111-2-15167 (WS11) x1 grinding spindle Q 36-12, complete 9 JKP x1 workhead spindle BP 60-25 with W25 collet reception x1 dust extraction unit x1 foot switch 9 M - operation of infeed Z-axis by foot pedal. Infeed stroke sleeplessly adjustable - ref: 111-2-15740 x1 LED machine lamp 24V/2.6W x1 digital display 4DZ + X +Y-MZ + digital indications for axes Z, X and Y - ref: 111-2-47178 x1 ISOMA microscope - optic from the front x1 ISOMA microscope - optic from the top x1 radius grinding attachment 25ABP - ref: 111-2-23294 x1 dividing head TS20 (6°) for radius grinding attachment 20ABP/25ABP - ref: 111-2-42192 x1 Touch-Test TT acoustic touch control (grinding wheel to workpiece) - ref: 56-4050 x1 Headset TT-K Stereo - ref: 56-4755

Request for a quote

KRAFFTER MACHINE TOOLS

France

Stroke X axis: 650 mm Max. Stroke speed X axis: 4000 mm/min Working feed X axis: 0 - 1800 mm/min Stroke Y axis: 450 mm Working feed Y axis: 0 - 1800 mm/min Stroke Z axis: 130 mm Min. Stroke speed Z axis: 0.5 mm/min Max. Stroke speed Z axis: 12000 mm/min Stroke frequency Z axis: max. 4 Hz Stroke W axis: 500 mm Planetary speed C axis: 5 - 250 rpm Max. Stroke speed W axis: 800 mm/min Stroke U axis (radial feed): 5.5 mm Distance between columns: 750 mm Table length: 770 mm Table width: 630 mm Clearance between grinding motor and table: 585 mm Max. load on table: 500 Kg Supply voltage: 400 V Weight: 4550 Kg EQUIPMENT INCLUDED: x1 HI-CUT pack including: -work area protection -exhaust system with electrostatic air filter -fire protection system (to be assessed by a qualified body) -automatic paper tape filtration unit x1 grinding motor x1 cable for grinding motor Machine visible under power in our premises by appointment.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KRAFFTER MACHINE TOOLS

France

CNC control: FANUC 31i Number of axes: 7 Stroke Y axis: -/+ 40 mm Stroke Z1 axis: 340 mm Stroke X1 axis: 180 mm Stroke Z2 axis: 440 mm Stroke X2 axis: 195 mm Rapid traverse rate X axis: 30000 mm/min Rapid traverse rate Z axis: 30000 mm/min Rapid traverse rate Y axis: 10000 mm/min Spindle nose: DIN 55026 A size 4 Spindle through bore: 42 mm Max. spindle speed: 8000 rpm Spindle power: 7 kW Counter spindle nose: DIN 55026 A size 4 Counter spindle through bore: 26 mm Max. counter spindle speed: 8000 rpm Counter spindle power: 3.8 kW Type of tool holders: VDI 25 Turret indexing time: 0.4 s/pos Turret 1: SAUTER Number of tool stations - Turret 1: 12 Number of tool stations driven - Turret 1: 12 Max. speed driven tools - Turret 1: 6000 rpm Turret 2: SAUTER Number of tool stations - Turret 2: 12 Number of tool stations driven - Turret 2 12 Max. speed driven tools - Turret 2: 6000 rpm + EQUIPMENT INCLUDED

Request for a quote

KRAFFTER MACHINE TOOLS

France

CNC control: FANUC 31i - MODEL A Distance between chucks: 639 mm Max. turning diameter: 255 mm Height of centres over carriage: 270 mm Stroke Z1 axis: 500 mm Stroke X1 axis: 190 mm Stroke Y1 axis +/-: 40 mm Stroke Z2 axis: 500 mm Stroke X2 axis: 190 mm Stroke Y2 axis +/-: 40 mm Rapid traverse rate X axis: 16000 mm/min Rapid traverse rate Z axis: 20000 mm/min Rapid traverse rate Y axis: 12000 mm/min Axes acceleration: 1g Spindle nose: ASA 8" A2 Max. bar diameter: 66 mm Spindle through bore: 77 mm Max. spindle speed: 4000 rpm Spindle power: 15 kW Spindle torque: 136 Nm Counter spindle nose: ASA 6" A2 Max. bar diameter counter spindle: 52 mm Counter spindle through bore: 61 mm Counter spindle stroke: 635 mm Max. counter spindle speed: 5000 rpm Counter spindle power: 7.5 kW Counter spindle torque: 68 Nm Turret indexing time: 0.1 s/pos + EQUIPMENT INCLUDED

Request for a quote

KRAFFTER MACHINE TOOLS

France

CNC control: Fanuc 0i-TB Number of axes: 7 Max. cutting diameter: 42 mm Max. turning length: 100 mm Stroke Z1 axis: 246 mm Stroke X1 axis: 165 mm Stroke Y1 axis: +/- 40 mm Stroke Z2 axis: 525 mm Stroke X2 axis: 70 mm Rapid traverse rate X axis: 18000 mm/min Rapid traverse rate Z axis: 20000 mm/min Rapid traverse rate Y axis: 12000 mm/min Spindle through bore: 43 mm Min. spindle speed: 60 rpm Max. spindle speed: 6000 rpm Increment C-axis: 0.02 ° Spindle power: 11 kW Counter spindle through bore: 36 mm Min. counter spindle spindle speed: 67 rpm Max. counter spindle speed: 7000 rpm Counter spindle increment C-axis: 0.02 ° Counter spindle power: 5.5 kW Max. tool holder cross-section: 20 mm Number of tool stations driven - Turret 1: 12 Max. speed driven tools - Turret 1: 4000 rpm Indexing time - Turret 1: 0.25 s/post Number of tool stations - Turret 2: 6 Indexing time - Turret: 0.20 s/post Live tools power: 2.5 kW + EQUIPMENT INCLUDED Machine visible under power

Request for a quote

KRAFFTER MACHINE TOOLS

France

TECHNICAL CHARACTERISTICS : Year of manufacturing :2004 CNC control: FANUC 180i-MB Stroke X axis: 500 [mm] Min. Stroke speed X axis: 0.0001 [mm/min] Max. Stroke speed X axis: 2000 [mm/min] Stroke Y axis: 300 [mm] Min. Stroke speed Y axis: 0.0001 [mm/min] Max. Stroke speed Y axis: 2000 [mm/min] Stroke Z axis: 140 [mm] Min. Stroke speed Z axis: 0.0001 [mm/min] Max. Stroke speed Z axis: 2000 [mm/min] Stroke W axis: 350 [mm] Planetary speed C axis: 1 - 300 [rpm] C axis max. speed: 20 [rpm] Max. Stroke speed W axis: 2000 [mm/min] Stroke U axis (radial feed): 11 [mm] Table length: 610 [mm] Table width: 305 [mm] Supply voltage: 400 [V] ADDITIONAL INFORMATION: x1 spindle DÄNZER DHB 0911.000 WW x1 oil cooler TURMOIL model OCO-33 RO x1 mist extraction unit FILTERMIST model F600 x1 MOORE Autosize tool edge probe x1 MOORE TOOL automatic wheel dresser x16 tool holders x1 RENISHAW OMP 40 workpiece probe x1 MOORE TOOL clamping box Full technical documentation

Request for a quote

INTERLINEX B.V.

Netherlands

Impact puller: weight 940 gr and 380 mm long. Inside puller: 12 – 32 m

Request for a quote

INTERLINEX B.V.

Netherlands

M14 x 1,5 Delphi adapter M17 x 1 Bosch adapter M20 x 1 Denso adapter M25 x 1 Siemens adapter M27 x 1 Siemens adapter M27 x 1 Bosch injector-nozzle adapter Trekker met M14 x 1,5P 4-piece injection nozzle socket 100L 25, 27, 29 en 30mm (6Pt)

Request for a quote

INTERLINEX B.V.

Netherlands

Hose clamps: 1 x (Ø 0 - 45 mm) 1 x (Ø 0 - 48 mm) 1 x (Ø 0 - 65 mm) 1 x (Ø 0 - 45 mm) 1 x (Ø 0 - 38 mm) forged 1 x (Ø 0 - 30 mm) 1 x (Ø 0 - 70 mm)

Request for a quote

INTERLINEX B.V.

Netherlands

Tools reinforces with fiberglass Suitable for the disassembly for door panels, trim, rubber joints, instrument panels, switches and rearview mirror glasses.

Request for a quoteResults for

Be tools - Import exportNumber of results

44 ProductsCountries

Company type