- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- be tools

Results for

Be tools - Import export

DOGA MAKINA

Turkey

381 mm four jaw power chuck with 100mm through hole and max speed of 2800rpm.

Request for a quote

DOGA MAKINA

Turkey

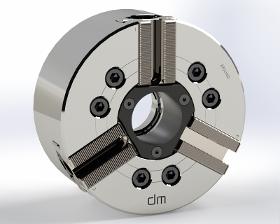

450mm three jaw standard power chuck with closed centre. made of a high-quality steel alloy. The hydraulic chuck's necessary parts are machined, and all of its components have been strengthened. Its design is extremely powerful and precise. Hydraulic mirrors from of the 2017 model new generation are constructed mainly in Turkey. The connection flange for the Standard Connection is ISO-A. It operates with all types of CNC workbenches. Plug and play Open center, suitable for bar feeder turning. Boxed, assembled, ready to use as a complete set. The mirror is shipped with soft feet. It is guaranteed for 1 year. (Except user error) Our products are 100% controlled. Each product is connected to the CNC workbench and controlled.

Request for a quote

DOGA MAKINA

Turkey

450mm three jaw standard power chuck with closed centre. made of a high-quality steel alloy. The hydraulic chuck's necessary parts are machined, and all of its components have been strengthened. Its design is extremely powerful and precise. Hydraulic mirrors from of the 2017 model new generation are constructed mainly in Turkey. The connection flange for the Standard Connection is ISO-A. It operates with all types of CNC workbenches. Plug and play Open center, suitable for bar feeder turning. Boxed, assembled, ready to use as a complete set. The mirror is shipped with soft feet. It is guaranteed for 1 year. (Except user error) Our products are 100% controlled. Each product is connected to the CNC workbench and controlled.

Request for a quote

DOGA MAKINA

Turkey

Production with Material (Manufacturing) : Our company provides the material needed for the manufacturing of the requested part. After engraving and doing quality control in accordance with the technical drawing measurements, our company ships the buying company the product with final reports. ⦁ Production without Material (Engraving) : Buying company provides the material themselves and sends it to our company. This could be casting or any type of material. Materials that arrive to our company are first controlled in terms of their measurements. When they are approved, our company prepares a manufacturing plan/program and starts working on specimens. Part with taken specimens are delivered to the buying company. With the approval of the buying company, manufacturing begins, and after doing its quality control it is delivered to the buying company with its final measurement reports.

Request for a quote

DOGA MAKINA

Turkey

Pin and bushings, especially in casting sector, used in centered casting. Casts need to merge together in a sensitive manner and this effects the quality of the products that will come out of it. Heat treating quality and materials that are determined in the technical drawing carry a great importance for this reason, we dont suggest false heat treating process and equivalent materials in this subject.

Request for a quote

DOGA MAKINA

Turkey

450mm three jaw standard power chuck with closed centre.

Request for a quote

DOGA MAKINA

Turkey

450mm three jaw standard power chuck with closed centre. made of a high-quality steel alloy. The hydraulic chuck's necessary parts are machined, and all of its components have been strengthened. Its design is extremely powerful and precise. Hydraulic mirrors from of the 2017 model new generation are constructed mainly in Turkey. The connection flange for the Standard Connection is ISO-A. It operates with all types of CNC workbenches. Plug and play Open center, suitable for bar feeder turning. Boxed, assembled, ready to use as a complete set. The mirror is shipped with soft feet. It is guaranteed for 1 year. (Except user error) Our products are 100% controlled. Each product is connected to the CNC workbench and controlled.

Request for a quote

DOGA MAKINA

Turkey

610mm four jaw standard power chuck with closed centre.

Request for a quote

DOGA MAKINA

Turkey

610mm three jaw standard power chuck with closed centre. made of a high-quality steel alloy. The hydraulic chuck's necessary parts are machined, and all of its components have been strengthened. Its design is extremely powerful and precise. Hydraulic mirrors from of the 2017 model new generation are constructed mainly in Turkey. The connection flange for the Standard Connection is ISO-A. It operates with all types of CNC workbenches. Plug and play Open center, suitable for bar feeder turning. Boxed, assembled, ready to use as a complete set. The mirror is shipped with soft feet. It is guaranteed for 1 year. (Except user error) Our products are 100% controlled. Each product is connected to the CNC workbench and controlled.

Request for a quote

DOGA MAKINA

Turkey

530mm three four standard power chuck with closed centre.

Request for a quote

DOGA MAKINA

Turkey

530mm three jaw standard power chuck with closed centre.

Request for a quote

DOGA MAKINA

Turkey

381 mm three jaw power chuck with 100mm through hole and max speed of 2800rpm.

Request for a quote

DOGA MAKINA

Turkey

304 mm four jaw power chuck with 91mm through hole and max speed of 3300rpm.

Request for a quote

DOGA MAKINA

Turkey

304 mm three jaw power chuck with 91mm through hole and max speed of 3300rpm.

Request for a quote

DOGA MAKINA

Turkey

254 mm three jaw through hole power chuck.

Request for a quote

DOGA MAKINA

Turkey

254 mm three jaw through hole power chuck.

Request for a quote

DOGA MAKINA

Turkey

254 mm three jaw through hole power chuck.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DOGA MAKINA

Turkey

210 mm three jaw power chuck with 52mm through hole and max speed of 5000rpm.

Request for a quote

DOGA MAKINA

Turkey

210 mm two jaw power chuck with 52mm through hole and max speed of 5000rpm.

Request for a quote

DOGA MAKINA

Turkey

169 mm three jaw power chuck with 45mm through hole and max speed of 6000rpm.

Request for a quote

DOGA MAKINA

Turkey

169 mm two jaw power chuck with 45mm through hole and max speed of 6000rpm.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

The best of both worlds! Insufficient stability was a fact increasingly associated with the VDI system in recent years. As a result, block tools were preferred more often, although the VDI tools still offer greater diversity and flexibility. So the next step appeared obvious: combining the best of both systems. In cooperation with DMG, we developed the EWS ProLine system in order to fully utilize the potential of new lathes. While EWS ProLine features a conventional VDI shank, it can be optionally mounted to the turret using four screws. For instance, the flexibility of the VDI system can be utilised for lighter machining, and the stability properties of block tools can be utilised for heavy cutting. The angular position of the radial tools is ensured through the Trifix®, the alignment system. Cutting data similar to HSK63 machining centres? The professional audience at the EMO 2011 watched an impressive live demonstration: on a Gildemeister CTX Beta 1250 4A, two surf

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

EWS goes milling With its latest range of angular heads, EWS brings its trusted technology with new features to machining centres. The system range was presented to the public for the first time at EMO 2015. An elegant design houses high-performance technology, or to put it simply Precision meets Motion. Advantages: the smart solution for compensating for there not being a machining axis Machining hard-to-reach parts Centre boring stepless angle adjustment around the horizontal axis, with tangentially acting double cone clamp MR > 250 Nm Prerequisite: The prerequisite is a "stop block" on the machine. This prevents the entire unit from turning while simultaneously defining the position of the angel of rotation. Variations: basic duplex offset Request form: PDF

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

High-speed thread cutting with reversing kinematics The new EWS Tapmatic thread cutting head for driven tools enables thread cutting processes without having to reverse the direction of rotation thanks to its reversing kinematics. This saves time and energy and protects the motor – all this with a defined depth of thread. The units are available for M3-M12 threads.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Emulsion can do more than just cool... At least when using EWS Spinjet, the coolant is used to drive a turbine which allows the tool to rotate to up to 50,000 rpm, depending on the type. The turret's tool drive stops moving during this process! See the attached flyer for the technical requirements and details. Download Manual: PDF

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Trifix® is the new adjusting system for Gildemeister multi tasking machines. The double sided adjusting system is guided by a very precise key way at the surface of the turret. The plates are preloaded, and the resiliency in the adjusting system eliminates static redundancy. This allow the exact position of the tool to be secured and significantly reduces the setup time of the machine. Because this is a highly sophisticated precision instrument it is not possible to use double serrated tool shafts. The tool is supplied fully adjusted and can be used right away. EWS is the DMG system partner for this tool generation. Trifix® advantages: Repeat accuracy below 6 µm at radius of 200 mm High positioning accuracy from one station to another (0.01 mm) Driven tools and static tool holders are completely aligned Static tool holders can be used together with additional drill pattern for mounting Heavy duty spindle noses can be used together with additional d

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Mount tools safely and in the correct position while remaining flexible, all this is possible with the UMB100 mounting unit. The tool clamping units can be changed quickly, making the system an ideal mounting aid for multi-tasking machines. It only takes a few seconds to replace an adapter. The unit with snap-in swivel can be pivoted 4 x 90° at the touch of a button so that even angled holders can always be mounted in the ideal position. Universal mounting block UMB100 Tool holder for VDI holding fixtures Tool holder for Varia VX Tool holder for steep-angle taper holding fixtures

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Keyway broaching on lathes is a common thing. What is new is to speed up this operation with low stress for the machine! Slot is driven by the tool turret of the machine, with the input rotary motion being converted to a translation with superimposed lift-off function. This makes programming extremely easy. The keyway broaching unit is positioned in the prepared bore – in such a way as to make the extended tappet oriented to the end position in the Z axis. The depth of the slot is produced by a constant X-feed moving between 0.04-0.08 mm/stroke. The speed of the spindle ranges between 400 R/min – 1,000 R/min, with one rotation corresponding to a complete stroke. This way, for instance, a feather key groove with a width of 6 mm and a depth of 5 mm is produced within 7.5 sec. (800 R/min and 0.05 mm feed/rotation). With this operation it is important that the chip can break at the end of the groove, that is that a cut-in or a bore exists.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Reaching concentricity 0 using a simple collet chuck and this within one minute: this is Zero-Zero. The specifically designed clamping nut with 6 symmetrically arranged screws at the circumference makes this step possible. The clamping nut is split, so that the inner ring can be minimally shifted. This simple technical finesse allows to eliminate tolerance additions. The machine operator only has to replace the previous clamping nut, which step opens up a new concentricity dimension – and this for a price starting at € 90.00. Zero-Zero is available for DIN 6499 collet chuck holders from ER 16-ER40.

Request for a quoteResults for

Be tools - Import exportNumber of results

670 ProductsCountries

- Italy (259)

- Germany (186)

- Turkey (53)

- Belgium (21)

- Switzerland (19)

- Netherlands (15)

- Spain (14)

- France (13)

- Bulgaria (12)

- Romania (10)

- Slovenia (10)

- China (8)

- Russia (8)

- United Kingdom (8)

- South Korea (6)

- Taiwan R.O.C. (6)

- Ukraine (5)

- Croatia (3)

- Serbia (3)

- Canada (2)

- Hungary (2)

- Poland (2)

- Austria (1)

- Greece (1)

- Luxembourg (1)

- Portugal (1)

- Sweden (1)

Company type

Category

- Tools & Hardware (367)

- Industrial tools (110)

- Hydraulic tools (55)

- Tools - garden (32)

- Electric tools (24)

- Milling - machine tools (20)

- Machine tools - metal machining (12)

- Electric vehicles (11)

- Measurement - Equipment & Instruments (9)

- Paint mixers and grinding machines (7)

- Punching machine tools (7)

- Bending machine tools (6)

- Building hand tools, non-power (5)

- Cutting - machine tools (5)

- Engineering - industrial contractors (5)

- Grinding - machine tools (4)

- Hand tools, non-power (4)

- Laser - cutting and welding machines (3)

- Machine tools, cutting - parts and accessories (3)

- Electric motors - dC (2)