- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- production line

Results for

Production line - Import export

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The Sunflower Seeds Shelling Production Line is a convenient processing line with high efficiency and less labor designed by our company for customers with large capacity requirements. It is a combined production line led by KTF5-3000 sunflower seeds shelling machine. The line is designed to confectionery sunflower seeds and remove the husk from the sunflower seeds before pressing the oil. The line processes oil sunflower, from which oil is then pressed. Description of the Line for Sunflower Dehulling (oil pressing): Intake and Cleaning: Sunflower is cleaned from larger and smaller impurities on Grain Impurity Screen Cleaner with an aspiration pre-cleaner. After cleaning, the sunflower is sorted. The Grain Grade Cleaner machine gains a dimensional spectrum of seeds suitable for dehulling. This is followed by destoning on a 125 MODEL DE-STONER.

Request for a quote

SHANGHAI DURA INDUSTRIAL CO., LTD.

China

Our factory’s Automatic Tag Eyelets Punching Machine mainly used to punch the eyelets on the tags or labels automatically. Features: 1. Using the frequency converter, touch screen , PLC , sensor electronic control system,easy to operate and control. 2. Different size and material tags can be puched with different size eyelets. 3. Automatic feeding eyelets. 4. The machine size is small and weight is light. 5.Low noise and simple maintenance. Specification: Speed:3000-5000pcs/h Size of tags:40*70mm Height of feeding material:250mm Size of tags:110*133mm Min thickness of tags:157g Max thickness of tags:700g Routine eyelet diameter :4mm eyelet +4.8mm hole size Voltage:3phase 380v Power:750w Machine size:700mm*900mm*1250mm Machine weight:350KGS Quality Control: All the machines will be inspected carefully before delivery.

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

The automatic Aerosol Filling Machine is composed of a push table, printing machine, automatic filling machine, weighing machine, water leak detector, nozzle machine, capping machine, and workbench. They are suitable for filling all kinds of liquid materials, such as thin liquid (kerosene), thick liquid (facial cleanser, PU foam) etc. Can be used in the food, chemical, pharmaceutical, and other liquid filling industry. The main part(including liquid filling and gas filling and sealing and boost pump) is to adopt pneumatic control.

YONGMING MACHINERY MANUFACTURING CO., LTD

China

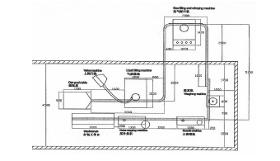

It involves a great deal of preparation to have a beautifully decorated design. We start with measuring the workshop area to get its length, width and height, then according to the entrance or exit of workshop, we are to plan the starter in the processing line. That includes how the materials are to be fed, pit making or feeding platform, and storage tank for materials reserving or processing directly. We need to consider how many materials would you be processing? And what is the degree of quality that you need? Where is the proper place for storage finished products? Where is the good exit for finished products transportation by truck? When all these information are gathered then we will be contributing to processing equipment.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The chili selecting production line is the latest production line developed by our company. Its main function is to improve the quality of chilis through sorting and grading. This production line has a reasonable design, large production capacity, strong practicality, good selection effect, and other characteristics.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

Based on years of experience in oilseed pressing and processing, Yongming machinery has designed two processes: cold pressing and hot pressing. The cold pressing process can retain active nutrients, reduce the color of crude oil, and produce oil with a strong flavor when using the hot pressing process to meet the needs of different users. Moreover, the oil yield is high and the production cost is low. The entire production line is equipped with advanced cleaning, pressing technology, and refining technology while paying attention to energy conservation and environmental protection, reducing emissions, saving costs, and maximizing corporate profits. Given the environmental protection and workshop hygiene requirements of modern industry, this production line is equipped with a complete dust removal system, and all connections for material transportation are equipped with suction to meet production and environmental protection requirements.

Request for a quoteResults for

Production line - Import exportNumber of results

8 ProductsCountries

Company type