- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- packing equipment

Results for

Packing equipment - Import export

GENERAL MEASURE TECHNOLOGY LTD.

China

B103B-12T is a weighing and batching equipment with intermittent feeding and continuous discharging. During the operation, it can discharge constantly with uniform mixing material and automatic flow correction. The flow rate can be adjusted from 0.5t to 12t per hour. The accumulated accuracy is under 0.1%. It can be widely used in food processing, chemical material processing, and other flow-batching applications.

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

PaxGo bagging scale, its self-optimizing controls can be precisely configured to your specific material flow, speed, and accuracy requirements. The new washdown version is specially designed for easy installation, dismounting and clean when the material needed to be refilled frequently.

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

Intelligent Bagging Scale with High Precision and Efficiency The automatic PaxGo bagging scale, and its self-optimizing controls can be precisely configured to your specific material flow, speed, and accuracy requirements

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

Intelligent Bagging Scale with High Precision and Efficiency The automatic PaxGo bagging scale, and its self-optimizing controls can be precisely configured to your specific material flow, speed, and accuracy requirements.

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

LF-5K is a linear feeder for granular materials and some powder materials. The vibratory feeding mechanism achieves multi-stage feeding. The pneumatic cylinder drives fast discharging. LF-5K linear feeder has a wide weighing range with high speed and high precision, which can be widely used in quantitative packaging machinery of grain, feed, chemical, rubber, and plastic industries.

Request for a quote

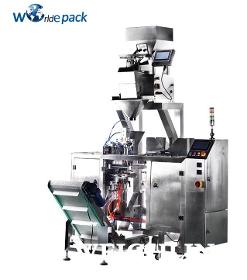

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1 Compatibility :Almost all small parts is able to pack with same machine except some parts which is able to hung each other so effect the accuracy and the parts which is too heavy or big as it may stuck in the weigher. 2 Change parts: When pack another parts , you can choose the exactly saved option in the interface screen then machine will adjust themself like the multihead weigher vibrating frequency , the speed . 3 Operation : Feeding the hardware parts into the hopper , set in the quantity or weight per bag on the touch screen , press start button then machine will fully automatic feeding the parts into multihead weigher for weighing , then filling into bag former which the machine parts make the bag , seal and cut the bag. 4 Printer: If you need the lot number or some logo or bar code on bag you can add the printer machine or label stick machine. You can edit the content like word or excel on the independent printer interface screen. 5 Accuracy :1%~2%.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

This is a fully automatical cartoning line , combined with weighing system and cartoning machine together. It's widely used in fastener and hardware fields, machine fully automatically weighing screw, nail, but, bolt or other small parts and filling into carton. 1. According to screw/special parts sample tailored to the vibration plates with a precise count control device, to ensure that every bag is accurate and correct. 2. Adopts pneumatic structure, the whole machine is more secure and reliable. 3. Advanced PLC control system and various automatic alarm protection functions, convenient for daily maintenance and reduced wastage. 4. It completes the whole procedure of metering, filling, bagging, date printing, charging(exhausting), and counting automatically. 5. Unique design of the packing seal technology, make the sealing nice and strong. 6. Equipped with a chain conveyor trailer, it can be fed by manual if the vibration plates are un-workable.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1. According to screw/special parts sample tailored to the vibration plates with precise count control device, to ensure that every bag is accurate and correct. 2. Adopts pneumatic structure, whole machine is more secure, stable, reliable. 3. Advanced PLC control system and various automatic alarm protection functions, convenient for daily maintenance and reduce wastage. 4. It completes the whole procedure of metering, filling,bagging,date printing, charging(exhausting),counting automatically. 5. Unique design of the packing seal technology, make the sealing nice and strong. 6. Equipped with chain conveyor trailer,it can be feed by manual if the vibration plates is un-workable.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

The machine is designed with pneumatic driving principle. According to the needs of users, it can be set to manual single flip work mode and automatic flip continuous work mode, two working modes, realize automation, simple operation, greatly reduce the operator's labor, improve productivity, save money time, labor saving, high efficiency and so on. Application: This series of vacuum packaging machines are suitable for vacuum packaging of food industry, kimchi, sauce products, soy products, seafood, frozen meat products and other materials to inhibit the reproduction of microorganisms such as bacteria, effectively avoid product oxidative mildew and spoilage, and prolong the time. Product shelf life or shelf life.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

The machine vacuum firstly,mix gases and fill gas mixture then sealing Thus, it provides high vacuum degree Ratio of gas mixture can be set accordingly to different food. After packed with modified gas it will prolong shelf lifemeanwhile maintain the origin taste,fresh colorand good nutrition. Application: All kinds of meat,fresh meat, aged meat, sausages, Seafood and fish,Dried fruits,Vegetables (processed by blanching, drying, or pickling),Ready to eat meals,Cheese (Not all cheese can be vacuum packed) Pasta, noodles totally dried cereals, corn kernels, peanuts, etc.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Lifting external vacuum packaging machine is vacuum or nitrogen-filled sealing packaging for electronic components, hardware, meat, dry goods, cloth wool products, whole grains, vegetables and fruits, pharmaceuticals, plastic raw materials, food, chemical raw materials, etc. It can achieve anti-oxidation, anti-corrosion, anti-mildew, moisture-proof and other fresh-keeping and quality-preserving effects. Lifting external vacuum packaging machine adopts no vacuum chamber, and the air nozzle directly vacuums or fills the packaging bag with nitrogen. The size of the packaging is limited, and it occupies a small space.This machine adopts long air nozzle design, and the air nozzle length can be adjusted freely from 0--200MM. In addition to the automatic lift transmission design, just press the lift switch. Automatically raise or lower to the appropriate vacuum position, so that the pumping and inflation speed is fast, the work efficiency is high, and the operation is simple and convenient.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Tabletop vacuum packaging machine suitable for electronic components, IC swashplates, semiconductors. Hardware, pharmaceutical chemical raw materials, food, meat, dry goods, vegetables, fresh fruits, beans and various fluids (such as with a small amount of liquid, semi-fluid, particles) and other materials, vacuum or nitrogen-filled sealing packaging. It can achieve anti-oxidation, anti-corrosion, anti-mildew, moisture-proof and other fresh-keeping and quality-preserving effects. Tabletop vacuum packaging machine adopts a vacuum chamber, which directly vacuums or fills the packaging bag with nitrogen, which occupies a small space and can be used on the counter at will. It is suitable for chain stores, supermarkets, specialty stores, laboratories, small or processed food production enterprises, etc. .Just step on the foot switch, then vacuum, inflate, seal, cool, etc., it is automatically completed at one time, and it is easy to use.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

External vacuum packaging machine four nozzles suitable for electronic components, IC swashplates, semiconductors. Hardware, pharmaceutical chemical raw materials, food, meat, dry goods, vegetables, fresh fruits, beans and various fluids (such as with a small amount of liquid, semi-fluid, particles) and other materials, vacuum or nitrogen-filled sealing packaging. It can achieve anti-oxidation, anti-corrosion, anti-mildew, moisture-proof and other fresh-keeping and quality-preserving effects. External vacuum packaging machine four nozzles adopts no vacuum chamber, which directly vacuums or fills the packaging bag with nitrogen. It occupies a small space and is flexible, convenient and practical to move at will. It is suitable for chain stores, supermarkets, specialty stores, laboratories, small or processed food production enterprises, etc.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

The automatic continuous stretch vacuum packaging machine is mainly formed by heating and stretching through the lower film, then filling the packaging into the formed lower film cavity, and then entering the heat sealing vacuum chamber to vacuum or inflate the packaging, and put the upper. The film is heat-sealed with the lower film to form a packaging bag, and the packaging is divided by cross-cutting and longitudinal cutting. The finished product output of packaging can be completed automatically at one time, the operation is simple, the labor force is greatly reduced, and the difficulty of recruiting is solved, thereby improving the product quality, beautifying the production environment, improving production efficiency, saving time, labor, and efficiency, etc. Real automation equipment. Application: All kinds of meat,fresh meat, aged meat, sausages, Seafood fish,Dried fruits,Vegetables ,Ready to eat meals,Cheese, Pasta, noodles totally dried cereals, corn kernels, peanuts, etc.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

High-speed modified atmosphere packaging machine, high production efficiency, suitable for medium and large batch packaging. Greatly reduce the labor force and solve the problem of difficult recruitment. Thereby improving the product grade and saving labor costs.It is suitable for various specifications of trays, the mold can be customized and replaced, and one machine can be used for multiple purposes.Can be integrated with other supporting systems (such as automatic box drop, feeding, metal detection, weighing and labeling machine, etc.)Modified atmosphere packaging machine is widely used in: cooked meat, fruits and vegetables, pickled products, seafood, shellfish, fresh meat, poultry, bakery and other boxed food packaging. In locking the original nutrition and mouth of the food.At the same time, it prolongs the shelf life of goods.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

The product is suitable for fast and efficient modified atmosphere fresh-keeping packaging of chilled fresh meat, cooked meat products, fast food, cakes, rice noodles, cheese, soy products, aquatic products, poultry meat, etc. It has the characteristics of keeping food quality, freshness, color, shape and taste. The continuous modified atmosphere fresh-keeping packaging machine is a box-type modified atmosphere fresh-keeping packaging machine launched by the company for cold fresh meat, cooked food, etc. The food is isolated from the outside air, and the tray is filled (2-3 kinds of gases are mixed according to the characteristics of the food) to keep the packaged food in its original flavor and appearance for a long time, and to inhibit various bacteria and microorganisms to the greatest extent. breeding. Thereby extending the shelf life or shelf life of the food.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1. Rotary packing machine combinate with the multi-heads weighing machine, Z-type conveyor, platform, accurate measurement, fast speed, low defective rate, low noise. 2. Eight stations rotary design to automatic control a series of processes from bag-giving, coding,bag-opening, filling, sealing, and finished products. It also automatic-check bag situation, filling and sealing situation to prevent waste of bags and materials. 3. The main configuration is the Siemens PLC control system, simple operation, and easy maintenance. 4. The machine uses premade pouch, you have more choice for the bag type and excellent appearance. 5. The lifting system is suitable for a wide range of industries, like food fodder, chemical, and so on granule material packing. 6. Strictly follow the mechanical standards to production, ensure the quality, reduce late wear, and reduce parts replacement. 7.SUS304 stainless steel is used for the contact part with products to ensure the cleanliness of the product.

Do you sell or make similar products?

Sign up to europages and have your products listed

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

It’s fully automatic counting and packing machine for Furniture kit and hardware spare parts.You only need to put the spare parts into the hopper and roll film on the packing machine, set in the quantity that you need to in bag and open the machine. Feature: 1. According to screw/special parts sample tailored to the vibration plates with precise count control device, to ensure that every bag is accurate and correct. 2. Adopts pneumatic structure, whole machine is more secure, stable, reliable. 3. Advanced PLC control system and various automatic alarm protection functions, convenient for daily maintenance and reduce wastage. 4. It completes the whole procedure of metering, filling,bagging,date printing, charging(exhausting),counting automatically. 5. Unique design of the packing seal technology, make the sealing nice and strong. 6. Equipped with chain conveyor trailer,it can be feed by manual if the vibration plates is un-workable.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

It’s a fully automatic counting and packing machine for Furniture kits and hardware spare parts. Widely used in fasteners, hardware, furniture, and bathroom field. You only need to put the spare parts into the hopper and roll film on the packing machine, set in the quantity that you need to in the bag and open the machine. The machine will automatically count the spare parts and make the film to be a bag, filling the spare parts into the bag, sealing, and cutting. Feature: 1. According to screw/special parts sample tailored to the vibration plates with a precise count control device, to ensure that every bag is accurate and correct. 2. Adopts pneumatic structure, the whole machine is more secure, stable, and reliable. 3. Advanced PLC control system and various automatic alarm protection functions, convenient for daily maintenance and reduced wastage. 4. It completes the whole procedure of metering, filling, bagging, date printing, charging(exhausting), and counting automatically.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

It’s a fully automatic counting and packing machine for Furniture kits and hardware spare parts like screws, bolts, nuts, washers, springs, and plugs. High precision and fast, save the labor cost you. Widely used in fasteners, hardware, furniture, and bathroom field. You only need to put the spare parts into the hopper and roll film on the packing machine, set in the quantity that you need to in the bag and open the machine. The machine will automatically count the spare parts and make the film to be a bag, filling the spare parts into the bag, sealing, and cutting. The lot number or other printing information is an optional device. Feature 1. According to screw/special parts sample tailored to the vibration plates with a precise count control device, to ensure that every bag is accurate and correct. 2. Adopts pneumatic structure, the whole machine is more secure, stable, and reliable. 3. Advanced PLC control system and various automatic alarm protection functions, convenient for daily

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Equipped high-quality performance various weight filler and mini doypack machine with auto ziplock opener and output conveyor, date printer as an option for solid granules, powder, liquid, paste, etc. Apply for different premade pouch types, such as Custom Packaging Styles flat Bottomed Pouch, Stand Up Pouch, Quad Seal Bag, Flat Pouch – 3 Side Seal Bag, Shaped Pouch, Retort Pouch, Kraft Paper Bags. Bulk material feeding conveyor as an option available Various weight fillers such as auger filler, multi-head, linear, pump filler, etc. Supporting stand Mini Doypack Machine Output conveyor Metal detector and weight checker as option

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

The desiccant pouch packing machine automatically measure the desiccant via the cup or weigher according to your setting parameter in touch screen, packing machine will form the roll nonwoven fabric to be a sachet according to your design, normally it’s pillow pouch,side sealing pouch, stick bag . Then cup or weigher will filling the measured desiccant into the formed sachet and sealing with ultrasonic cold sealing model which is suitable for nonwoven fabric .You can add feeder instead of manually add self hot powder into weigher , add ink printer so print the lot number or LOGO on the sachet , add end weigher checker so it will detect the sachet which weight is beyoud your accept tolerance.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

The ultrasonic sachet sealing machine with Weigher automatically weighing the herbal according to your setting parameter in weigher touch screen, packing machine will form the roll nonwoven fabric to be a sachet according to your design, normally it’s pillow pouch,side sealing pouch, stick bag . Then weigher will filling the measured herbal into the formed sachet and sealing with ultrasonic cold sealing model which is suitable for nonwoven fabric .You can add feeder instead of manually add herbal into weigher , add ink printer so print the lot number or LOGO on the sachet , add end weigher checker so it will detect the sachet which weight is beyoud your accept tolerance.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1.Ultrasonic controller performance stable, the sealing model got the even temperature so bag sealing is tight and nice, help you got more customer. Different nonwoven materials, soft or hard, thickness will need different perfect sealing temperatures so we will adjust the Ultrasonic controller according to your exact material. 2. Bag former it's hand-made by our craftsman from completely one aluminum, so it's very smooth and anti-rust. If the bag former is welded from several irons then its rough surface and easy rust. It will be got the film stucked and affect the procedure. You can change the bag former to make a different width bag. 3. Sealing model and Cutter The sealing mode is made of titanium steel which is wear-resistant, ultrasonic sealing, easy to operate, and maintain. Double nonwovens packing avoids material leakages, Sealing pattern can be customized according to your requirement.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Compared to the traditional shrink wrapper, our Flow Wrapping machine’s main features are high speed and less material waste, the speed has increased by 2-10 times, and you can save labor costs and time, it is suitable for bowl noodles, milk tea, cup products, frozen products, food boxes, cosmetics, clinker bottles, coil incense, and another shrink packaging. The product that has been packed with the film is sent to the automatic shrinking tunnel through the conveyor and run in the shrinking tunnel through the mesh belt, and the thermal energy efficiency during the operation can achieve the purpose of shrinking. The unit adopts a step-less speed regulation device; and cooperates with an automatic dual temperature controller to control the temperature, through the circulation of hot air, the quality of the shrinkage of the film is more stable and beautiful. The unit has high equipment efficiency, compact structure, reliable operation, low noise, and convenient maintenance.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Four sides horizontal wrap machine fully automatically wrap the products with 2 kinds of film or one kind of film but 2 rolls, consists of a special controller and touch screen for maintenance and control and 4 sets of servos.It is suitable for the packaging of solid sheet items in the pharmaceutical, health care, chemical, light industry, and food industries such as composite film, aluminum plastic film, a pure aluminum film, aluminized film, coated paper, etc., Bodywarmer stick, antipyretic stickers, infusions Heaters, pain relief plasters, medical accessories stickers, game cards, recharge cards, commemorative coins, kiss stickers, temperature measurement stickers, single-piece sanitary napkins, flaky tofu skin, spicy fish fillets, biscuits, etc.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Automatic Side Sealer Shrink Wrap Machine is a fully automatic unmanned operation of an economic side sealing packaging machine, that is widely used in the assembly line of mass production and packaging. It uses an electronic eye to detect products as they pass through on the conveyor. After products pass, a single-sealing arm running perpendicular to the film closes behind the product. As the product continues to pass to the conveyor, a side sealing wheel makes the final seal enclose the product. The advantage of the side seal machine comes from the ability to wrap longer products. The width of the product is limited to the verticle sealing bar, but the length can be as long as needed. A perfect option for shrink wrapping molding, pipes, wood, and other elongated items. The horizontal knife in the sealing part adopts a vertical drive, and the vertical knife adopts a constant temperature side sealer. The sealing line is straight and firm to achieve a beautiful sealing effect.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Irregular shaped sachet packing machines automatically finish the processes of pouch forming, filling, sealing, cutting, and date printing. The best feature is the pouch shape is irregular like round, strip, polygonal, bottle-shaped and so on. This machine can be used to make different shapes good-looking pouches according to customer requirements. And it is suitable for fruit juice, honey, ketchup, cream, shampoo, cosmetics, etc. Equipment Feature: 1. Smart PLC controller and display with high reliability, high stability, and extremely low error rate. 2. Servo motor control bag system with high precision bag making. 3. Full 304 stainless steel feeding hopper, more healthy and easy clean. 4. Less abrasion, high efficiency, and long service life. 5. Choose the appropriate feeding device according to the material, special material special pump, and prevent leakage.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

The product is suitable for fast and efficient modified atmosphere fresh-keeping packaging of chilled fresh meat, cooked meat products, fast food, cakes, rice noodles, cheese, soy products, aquatic products, poultry meat, etc. It has the characteristics of keeping food quality, freshness, color, shape and taste. Modified atmosphere fresh-keeping packaging machine is a box-type modified atmosphere fresh-keeping packaging machine launched by the company for cold meat, cooked food, etc. The basic principle of this packaging is to use high barrier materials (plastic trays and cover films) The outside air is isolated, and the tray is filled (2-3 kinds are mixed according to the characteristics of the food) to keep the packaged food in its original flavor and appearance for a long time, and to inhibit the growth of various bacteria and microorganisms to the greatest extent. Thereby extending the shelf life or shelf life of the food.

Results for

Packing equipment - Import exportNumber of results

66 ProductsCountries

Company type