- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metallized ceramics

Results for

Metallized ceramics - Import export

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Innovacera supplies precision metallized ceramic components in aluminum oxide ceramics for the military, medical, and aerospace industries. Through spray, needle, and brush coatings or screen printing our capabilities allow us to metallized on flat, cylindrical, and complex ceramic bodies. Moly-Manganese is the typical base coat materials used for metallization.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

In a development that could have a significant impact on the electronics industry, the latest ceramic metallized insulators are making strides in enhancing semiconductor packaging and related applications. These insulators offer a range of practical benefits that can improve the performance and durability of electronic components. Let’s take a closer look at what sets them apart: Key Features of Ceramic Metallized Insulators: 1. Stability and Strength: The ceramic material employed in these insulators boasts an even texture, ensuring every batch maintains stable quality and flexural strength. This consistency in material quality is pivotal for the reliability of electronic components. 2.Dense and Weldable Metal Layer: The metal layers in these insulators are densely applied, providing a smooth and even surface. This not only enhances their appearance but also makes them easy to work with, particularly in manufacturing processes.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Vacuum metalizing coater for plastic, glass, ceramic, stainless steel, metal etc. The coating experts of your own company. Full set solution for the coating production. We can help you to enter the pvd coating easily by our vacuum coating machine and full range service. We will provide with most suitable technology according to your requirements. We will make the special coating solution for each customer; combine the full set production technics to meet your requirements, to ensure high efficiency of production. Easy to implement. To many people unfamiliar with the process, pvd coating technology seems complicated. However, with the right investments and a good support, it is easier than expected. We developed a turnkey coating process that makes a pvd coating centre easy to implement. A complete coating process consists of several steps: stripping ; pre-treatment; quality control; cleaning & drying; fixturing&visual inspection; pvd coat ;quality control & thickness measurement etc

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Metallized Ceramic Componenets: Innovacera supplies precision metallized ceramic ring in aluminum oxide ceramics for the military,medical, and aerospace industries. Through spray, needle, and brush coatings or screen printing our capabilities allow us to metallized on flat, cylindrical, and complex ceramic bodies. Moly-Manganese is the typical base coat materials used for metallization.In order to achieve the welding between ceramic and metal, the ceramic surface firmly adheres to a layer of the metal film, which is ceramic metallization. Refractory-metalized aluminum oxide ceramics widely use in power grid tubes, vacuum interrupters, and similar applications where metal to ceramic joints of exceptional strength and hermeticity is required.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

DBC (Direct Bonded Copper) tenique denotes a special process in which the copper foil and the al2o3 or AlN (one or both sides) are directly bonded under appropriate high temperature. The finished super-thin DBC substrate has excellent electrical isolation,high thermal conductivity, fine solderability and high bonding strength.It may be structured just lick PCB to get etched wiring and has high curreng loading capability .Therefore DBC ceramic substrates have become the base material of tuture for both the construction and the interconnection techniques of high power semiconductor electronic circuits and also have been the basis for "chip on boaed" technology which repre-sents the packaging trend in century. Specification >Metallization thickness: 25 ±10um >Nickel thickness:2~10um >Pin full strength: 4200kgf/cm2 avg. (at Φ3.0mm pin)

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

High Hermeticity Metallized Ceramic Bushing /Innovacera Features: 1.Material: 96% Aluminia(AL2O3) 2.Coating Layer:Molybdenum-Mananese(Mo/Mn) 3.These metallized ceramics are ideal for high voltage, high vacuum and high pressure applicationos. So far the most widely-used and effective method for creating a leak-tight, robust joint between ceramic and metal is by brazing . A thin layer of metal deposited on a ceramic part enables brazing between ceramic and metal part that h as a different coefficient of thermal expansion. A layer of Molybdenum-Manganese is deposited with a typical thickness of 8 to 30 µm after sintering. The metallized surface receives a secondary coating of nickel to seal and improve wettability for later brazing.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Metallized Ceramic Componenets: Innovacera supplies precision metallized ceramic parts in aluminum oxide ceramics for the medical, and aerospace industries. Through spray, needle, and brush coatings or screen printing our capabilities allow us to metallized on flat, cylindrical, and complex ceramic bodies. Moly-Manganese is the typical base coat materials used for metallization.In order to achieve the welding between ceramic and metal, the ceramic surface firmly adheres to a layer of the metal film, which is ceramic metallization.Refractory-metalized aluminum oxide ceramics widely use in power grid tubes, vacuum interrupters, and similar applications where metal to ceramic joints of exceptional strength and hermeticity is required. Specification >Metallization thickness: 25 ±10um >Nickel thickness:2~10um >Pin full strength: 4200kgf/cm2 avg. (at Φ3.0mm pin) Available Ceramic Composition >94%,96%,99%,99.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Mo Mn Ceramic Feedthrough Ceramic Vacuum Electrodes The Ceramic Surfaces for Brazing, the surface must be metallized. Compare to Glass seal, Ceramic seal has exceptional resistance to thermal and mechanical shock as well as corrosion. While it requires more complex manufacturing processes and sophisticated engineering, the price is obviously higher. Advantages of Ceramic-to-Metal Seals * More solid, durable hermetic seal and better electrical insulation * Used for more harsh conditions, such as high and low (cryogenic) temperature, corrosive, high pressure, and high vacuum environments * High mechanical strength, less fracture when applied to high vibration and high g-load conditions * Shows strong bond and an excellent seal with metals and alloys, such as copper and Cu alloys (CuNi) and to nickel and Ni alloys.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Innovacera manufactures many kinds of metalized ceramic coil bodies for electrical inductors, including the H-shapes, U shape and Bone-shaped and so on. The main material of metalized ceramic coil bodies is 96 Alumina and the metallized coating material is W, Ni, Au etc. Our factory have more than 20 years of metalized ceramics producing experiences, can give a prompt solution for R&D project. The metalized bodies is partially metalized , ceramic inductor coil bodies cores can make very small size which it is big helpful for the electrical systems , wire-winding technique, electronics devices and electrical coils components miniaturization developed.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

High Hermeticity Metallized Ceramic Bushing Features: 1.Material: 96% Aluminia(AL2O3) 2.Coating Layer:Molybdenum-Mananese(Mo/Mn) 3.These metallized ceramics are ideal for high voltage, high vacuum and high pressure applicationos. So far the most widely-used and effective method for creating a leak-tight, robust joint between ceramic and metal is by brazing . A thin layer of metal deposited on a ceramic part enables brazing between ceramic and metal part that h as a different coefficient of thermal expansion. A layer of Molybdenum-Manganese is deposited with a typical thickness of 8 to 30 µm after sintering. The metallized surface receives a secondary coating of nickel to seal and improve wettability for later brazing. Applications: Electrical transmission and distribution Electronics industry Textile machinery Defense Medical electronics Automobile industry Sealing Solid Oxide Fuel Cells High temperature application

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic-to-Metal Seal The Ceramic Surfaces for Brazing, the surface must be metallized. Compare to Glass seal, Ceramic seal has exceptional resistance to thermal and mechanical shock as well as corrosion. While it requires more complex manufacturing processes and sophisticated engineering, the price is obviously higher.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

AMB (Active Metal Brazing) is for joining ceramics that are not wetted by 'conventional' brazes.By applying active metal like titanium to be added to the braze alloy, to achieve chemically reacts with the surface of the parent ceramic.Due to the coefficient of thermal expansion of Al2O3 (7.1 ppm/K), Si3N4 (2.6 ppm/K) and AlN (4.7 ppm/K) is close to that of silicon (4 ppm/K), Direct Bond Copper (DBC) and AMB are suitable substrates for robust packaging of bare dice since such assemblies.AMB is the promising thick film technology which can be applied to Power Electronics, Automotive Electronics, Home Appliances, Aerospace, Others. INNOVACERA provide DBC, DPC, and AMB technology for customized ceramic substrates, welcome to consult more.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Silicon carbide is a kind of inorganic non-metallic materials, with excellent mechanical strength and hardness, small creep deformation, good oxidation resistance, good corrosion resistance and good wear resistance, it is an ideal choice for high temperature engineering materials. Due to the outstanding properties, silicon carbide ceramic is also recognized as a mechanical sealing ring material better than metals, tungsten carbide, al2o3 ceramics and more. Place of Origin: China Material: Silicon Carbide (SiC) Color: Black/grey Material: Silicon Carbide Ceramics Volume density: 3.10-3.15 g/cm3 Max temperature: 1600°C Silicon carbide content: ≥98% Flexural Strength: ≥400 MPa Hardness: ≥ 92 HRA Size: Customizable Application: Industrial Furnaces Supply Ability: 5000000 Piece/Pieces per Month Packaging Details: Standard exporting packing Port of shipment: Xiamen Lead Time :15-30days Payment term: T/T,L/C etc.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Place of Origin:China Product Name:Tungsten Powder Chemical Composition:99.99%Pure Tungsten Powder Lead time:15days Port of shipment:Xiamen Payment term:T/T,L/C Application 1 For high proportion alloy, green bullets, alloy steel, drill, and products; 2 High-active nano powder can be used as the raw materials of high performance proportion alloy additive quantity (powder from 30% ~ 50%) and preparation of the silk road, and raw materials can be used as additive, high alloy materials, tungsten powder can significantly improve performance and reduce alloy sintering temperature and shorten the production cost saving time and sintering; 3 The nanometer powder can be used as the raw material, nanometer WC preparation of nanocrystalline cemented carbides. Due to the special nanometer powder, and can be used for pore structure ceramic metallization coating W-Mn method of tungsten powder materials.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Jaw plate and Side plate for Jaw crusher; Mantle, Concave for Cone Crusher; Blow bar and Hammer for Impact Crusher and Hammer/Metal crusher; Roller and Ring for Raymond Mill; Roller Liner and Disc Liner for Sand making VSI Crusher, Chocky bar and Wearing button for Excavator, which is in the material of High Manganese Steel Mn13Cr2/ Mn14Cr2/Mn17Cr2/Mn18Cr2/Mn22Cr2; High Chrome White Iron Cr20/Cr22/Cr24/Cr26, and its with Mo, Ni, Re, Ceramic, Alloy, Bi-metal etc wear-resistant materials. And HUAN-TAI products support for Shanbao, SBM, Liming, Shibang, Zenith, Metso, Sandvik, Barmac, Trio, TEREX, Pegson, Powerscreen, Kleemann, MINYU, Symons, Hazemag, Cedarapids, McClosey, Keestrack, Telsmith, Russian brands and other famous brands machine. We also can produce the wearing spare parts as per customers’ own drawings

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Jaw plate and Side plate for Jaw crusher; Mantle, Concave for Cone Crusher; Blow bar and Hammer for Impact Crusher and Hammer/Metal crusher; Roller and Ring for Raymond Mill; Roller Liner and Disc Liner for Sand making VSI Crusher, Chocky bar and Wearing button for Excavator, which is in the material of High Manganese Steel Mn13Cr2/ Mn14Cr2/Mn17Cr2/Mn18Cr2/Mn22Cr2; High Chrome White Iron Cr20/Cr22/Cr24/Cr26, and its with Mo, Ni, Re, Ceramic, Alloy, Bi-metal etc wear-resistant materials. And HUAN-TAI products support for Shanbao, SBM, Liming, Shibang, Zenith, Metso, Sandvik, Barmac, Trio, TEREX, Pegson, Powerscreen, Kleemann, MINYU, Symons, Hazemag, Cedarapids, McClosey, Keestrack, Telsmith, Russian brands and other famous brands machine. We also can produce the wearing spare parts as per customers’ own drawings

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Jaw plate and Side plate for Jaw crusher; Mantle, Concave for Cone Crusher; Blow bar and Hammer for Impact Crusher and Hammer/Metal crusher; Roller and Ring for Raymond Mill; Roller Liner and Disc Liner for Sand making VSI Crusher, Chocky bar and Wearing button for Excavator, which is in the material of High Manganese Steel Mn13Cr2/ Mn14Cr2/Mn17Cr2/Mn18Cr2/Mn22Cr2; High Chrome White Iron Cr20/Cr22/Cr24/Cr26, and its with Mo, Ni, Re, Ceramic, Alloy, Bi-metal etc wear-resistant materials. And HUAN-TAI products support for Shanbao, SBM, Liming, Shibang, Zenith, Metso, Sandvik, Barmac, Trio, TEREX, Pegson, Powerscreen, Kleemann, MINYU, Symons, Hazemag, Cedarapids, McClosey, Keestrack, Telsmith, Russian brands and other famous brands machine. We also can produce the wearing spare parts as per customers’ own drawings

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

DBC ceramic substrate: Direct bonded copper (DBC) substrates are commonly used in power modules, because of their very good thermal conductivity. They are composed of a ceramic tile (commonly alumina) with a sheet of copper bonded to one or both sides by a high-temperature oxidation process (the copper and substrate are heated to a carefully controlled temperature in an atmosphere of nitrogen containing about 30 ppm of oxygen; under these conditions, a copper-oxygen eutectic forms which bonds successfully both to copper and the oxides used as substrates). The top copper layer can be preformed prior to firing or chemically etched using printed circuit board technology to form an electrical circuit, while the bottom copper layer is usually kept plain. The substrate is attached to a heat spreader by soldering the bottom copper layer to it. 1. Thickness of substrate can be thin: 0.25mm,0.28mm,0.45mm,0.5mm,0.635mm,1.0mm,1.5mm, 1.8mm,2.0mm 2.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminum nitride ceramics have excellent electrical and thermal properties, and are considered to be the most promising high thermal conductivity ceramic substrate materials. In order to seal the package structure, mount components and connect input and output terminals, the surface and interior of the aluminum nitride ceramic substrate need to be metallized. The reliability and performance of ceramic surface metallization have an important impact on the application of ceramic substrates, and firm bonding strength and excellent air tightness are the most basic requirements. Considering the heat dissipation of the substrate, it is also required to have high thermal conductivity at the interface between the metal and the ceramic. The metallization methods on the surface of aluminum nitride ceramics include: thin film method, thick film method, high melting point metallization method, electroless plating method, direct copper cladding method (DBC), etc.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

DPC Ceramic Substrate Advantages: > In terms of shape processing, DPC ceramic substrate needs to be cut by laser, the traditional drilling and milling machine and punch machine can not be accurately processed, so the combination force and line width is also more fine. > The crystal performance of the metal is good; > The flatness is good; > The line is not easy to fall off; > The line position is more accurate, the line distance is smaller, reliable and stable, can be through the hole and other advantages.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

AMB Ceramic Substrate is a method to realize the bonding of ceramic and metal by reacting a small amount of active elements Ti and Zr in filler metal with ceramics to form a reaction layer which can be wetted by liquid filler metal. Advantage: The combination is achieved by chemical reaction between ceramic and active metal solder paste at high temperature, so its bonding strength is higher and reliability is better. Disadvantage: The reliability of AMB process depends largely on the composition of active filler metal, brazing process, brazing layer structure and many other key factors。 Specification >Metallization thickness: 25 ±10um >Nickel thickness:2~10um; >Pin full strength: 4200kgf/cm2 avg. (at Φ3.0mm pin)

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

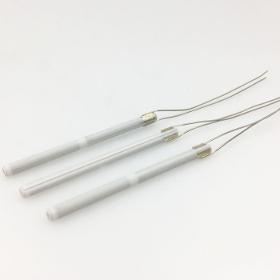

Ceramic Heater for Soldering iron & Station: Alumina Ceramic Heaters are produced by implementing unique metallization and ceramic lamination processes. Due to the advanced manufacturing techniques utilized in the electric element, Alumina Heaters can provide higher reliability than ever before.Currently, applications include use as innovative types of heaters in the automotive, medical and semiconductor industries. a.Based material: white alumina ceramic, and the content of alumina is no less than 95%.The tungsten slurry is printed on the ceramic tape, laminated by hot pressing, and thensintered under the protection of a hydrogen atmosphere at 1650 ° C b.Ni-wires:N6 Ni-wires with 0.6mm diameter c.Brazing material: siliver-copper braging alloy Application: We are producing High Quality 24V 110V 220V Heating Element for Soldering Station with the advantages of energy-efficient,long lifetime,high insulation,super fast heatin up and eco-friendly.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic crucible is the use of high purity powder, trace elements added, from the phase structure and microstructure of modified production.A smelting vessel. Products are aluminum oxide crucible and fully stabilized zirconia porous crucible, the former is mainly used for smelting and laboratory Firing other high melting point material, which is mainly used for the melting temperature with Pt,Rh, Au and other precious metal. Series: •Alumina ceramic crucible •Zirconia ceramic crucible •Conical or curved alumina ceramic crucibles •Cylindrical alumina ceramic crucibles •Rectangular crucibles •Special shaped crucibles •Alumina saggers Alumina ceramic crucible specifications: 5ml 10ml 15ml 20ml 25ml 30ml 50ml 100ml 150ml 200ml 250ml

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminium Oxide, Al2O3 is a major engineering material. It offers a combination of good mechanical properties and electrical properties leading to a wide range of applications. Alumina can be produced in a range of purities with additives designed to enhance properties. A wide variety of ceramic processing methods can be applied including machining or net shape forming to produce a wide variety of sizes and shapes of component. In addition it can be readily joined to metals or other ceramics using metallising and brazing techniques. Alumina based ceramics are by far the largest range of advanced ceramics made by INNOVACERA. Due to the important combination of properties, we have thoroughly researched the behaviour and characteristics of our Alumina products to give you the best possible component. Typical Alumina characteristics include: Good strength and stiffness Good hardness and wear resistance Good corrosion resistance Good thermal stability Excellent dielectric properties

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminium Oxide, Al2O3 is a major engineering material. It offers a combination of good mechanical properties and electrical properties leading to a wide range of applications. Alumina can be produced in a range of purities with additives designed to enhance properties. A wide variety of ceramic processing methods can be applied including machining or net shape forming to produce a wide variety of sizes and shapes of component. In addition it can be readily joined to metals or other ceramics using metallising and brazing techniques. Alumina based ceramics are by far the largest range of advanced ceramics made by INNOVACERA. Due to the important combination of properties, we have thoroughly researched the behaviour and characteristics of our Alumina products to give you the best possible component. Typical Alumina characteristics include: Good strength and stiffness Good hardness and wear resistance Good corrosion resistance Good thermal stability Excellent dielectric properties

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminium Oxide, Al2O3 is a major engineering material. It offers a combination of good mechanical properties and electrical properties leading to a wide range of applications. Alumina can be produced in a range of purities with additives designed to enhance properties. A wide variety of ceramic processing methods can be applied including machining or net shape forming to produce a wide variety of sizes and shapes of component. In addition it can be readily joined to metals or other ceramics using metallising and brazing techniques. Alumina based ceramics are by far the largest range of advanced ceramics made by INNOVACERA. Due to the important combination of properties, we have thoroughly researched the behaviour and characteristics of our Alumina products to give you the best possible component. Typical Alumina characteristics include: Good strength and stiffness Good hardness and wear resistance Good corrosion resistance Good thermal stability Excellent dielectric properties

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminium Oxide, Al2O3 is a major engineering material. It offers a combination of good mechanical properties and electrical properties leading to a wide range of applications. Alumina can be produced in a range of purities with additives designed to enhance properties. A wide variety of ceramic processing methods can be applied including machining or net shape forming to produce a wide variety of sizes and shapes of component. In addition it can be readily joined to metals or other ceramics using metallising and brazing techniques. Alumina based ceramics are by far the largest range of advanced ceramics made by INNOVACERA. Due to the important combination of properties, we have thoroughly researched the behaviour and characteristics of our Alumina products to give you the best possible component. Typical Alumina characteristics include: Good strength and stiffness Good hardness and wear resistance Good corrosion resistance Good thermal stability Excellent dielectric properties

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina cearmic bar is used when conditions exclude the use of metal, either for chemical reasons or because of excessive temperatures.Their main applications are between 1000 and 1800°C. They may be in directly contact with the medium or may be used as a gas-tight inner sheath to separate the thermocouple from the actual metal protection tube. Ceramic tubes should be mounted in a hanging position above 1200°C to prevent distortion or fracture due to bending stresses. Evenhair-line cracks can lead to contamination of the thermocouple resulting in drift or failure. High purity ceramic strip provide a broad range of engineering properties: High Temperature-Superior Strength-Corrosion Resistance-Thermal & Electrical Insulation along with other specialized characteristics. -Precision Close, Tight Tolerances, -Ceramic Bar & Ceramic Strip machined to customer specifications-Prototype to Production-Intricate ceramic machining -Alumina is widely used in automotive,petro-chemical

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconia is a very strong industrial ceramic with excellent properties in terms of hardness, fracture toughness and corrosion resistance; it solves the most common characteristic of ceramics-high brittleness. Its unique crack propagation resistance and high thermal expansion make it an excellent material for joining ceramics and metals such as steel. Due to the unique properties of zirconia, it is sometimes referred to as “ceramic steel”.

Request for a quoteResults for

Metallized ceramics - Import exportNumber of results

38 ProductsCountries

Company type

Category