- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- alumina

Results for

Alumina - Import export

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

INNOVACERA® Ceramic hot surface igniters for pellet boilers only need approx. 1/10 of the energy of that needed by hot air fans and ignition blowers. Their ignition capacity lies between 120 and 350 W. Depending on the positioning of the ignition element in the boiler, the ignition time of approx. 60 seconds is extremely short. This also means minimal emissions. Specification: Voltage: 120V / 230V Power: 150W / 170W / 200W / 230W Tube Size: OD10.5 × ID6.5 × L78 mm Supporting Socket: NO.7 Lead wire: 300mm / 400mm / 500mm / 900mm (Customized is accept) Range of temperature: 800~1100 °C Applications: Kerosene fan heater Wood pellet, wood chips stove or boiler Small scale biomass industrial furnace ignition Incense burner

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

INNOVACERA® Ceramic hot surface igniters for pellet boilers only need approx. 1/10 of the energy of that needed by hot air fans and ignition blowers. Their ignition capacity lies between 120 and 350 W. Depending on the positioning of the ignition element in the boiler, the ignition time of approx. 60 seconds is extremely short. This also means minimal emissions. Specification: Voltage: 120V / 230V Power: 300W / 350W Tube Size: OD11.5 × ID6.5 × L108 mm Supporting Socket: NO.43 Lead wire: 300mm / 400mm / 500mm / 900mm (Customized is accept) Range of temperature: 800~1100 °C Applications: Kerosene fan heater Wood pellet, wood chips stove or boiler Small scale biomass industrial furnace ignition Incense burner

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina Ceramic Beads are used large quantity in the world, because of their excellent consistence and reliability. Products to these specifications are manufactured from very high quality chemical-porcelain clay materials, which has quite excellent stability, high mechanical strengthand resistance to thermal shock. This makes them all ideal choice for support of all types of catalyst.widely used for heat retention ,equilibration media,as ethylene dryers,High temperature Shift ,Low temperature shift,Ethylene cracking and drying.are widely utilized as the covering or supporting materials of the catalyst in the reactors and the packing in the columns in such varied areas as petroleum, chemical industry, chemical fertilizer, natural gas and suport or protect the active catalyst , which especially have the comparatively good mechanical strength. Feature: * Excellent abrasion resistance * High purity * Excellent corrosion resistance * Energy saving of grinding and dispersion

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

INNOVACERA Alumina Ceramic hot surface igniters for pellet boilers only need approx. 1/10 of the energy needed by hot air fans and ignition blowers.Their ignition capacity lies between 120 and 350 W. Depending on the positioning of the ignition element in the boiler, the ignition time of approx. 60 seconds is extremely short. This also means minimal emissions. Alumina Ceramic Heater Specification: > Voltage: 120V/230V > Power: 160W, 180W, 210W, 225W, 230W, 240W, 255W > Tube Size: OD10.5 × ID6.5 × L90 mm > Supporting Socket: NO.4/NO.5/NO.6/NO.29 > Lead wire: 300mm/400mm/500mm/900mm (Customized is accept) > Range of temperature: 800~1100 °C Ceramic igniter technology benefits: * A fraction of the energy consumption compared to element heater. * Long-lasting (non-aging). * Time to ignition 60~90 seconds. * Tested to 100,000 cycles. * Easy to install and retrofit. * 800~1100°C at steady-state temperature. * Impervious to oxidation and corrosion.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The material of ceramic reflector is 99% Al2O3.Its green body is fired at a suitable temperature to retain the proper porosity and strength. The surface of the ceramic reflector is coated with a high reflectivity ceramic glaze ,so compared with the gold-plated reflector , its has long service life and diffuse reflection. Prime Features: - Surfaces can be sealed and coated with a solarization-resistant glaze to give high bulk refectivity - 98% reflectance efficiency at 600-1000nm - Reflectance efficiency exceeds 96% across the wavelength range 400-1200nm (see curve) - Controlled porosity, Good thermal conductivity, High electrical resistivity. Physical Characteristics: - Color: White - Density: 3.1Mg/m^3 - Porosity: 22% - Flexural strength: 170Mpa - Coefficient of thermal expansion: 7.9×10^-6--/С (200~500℃) 9×10^-6/С (200~1000℃)

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

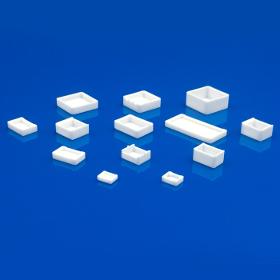

Alumina Crucibles are manufactured for more than 20 years and have a skill production technology in different shapes and range of sizes from few milliliters to several liters,these fully dense, high purity an high temperature use,fine grain products find use in a range of high temperature applications such as metal processing / molten glass, rapid thermal cycling, gemstone purification for jewelry industry etc. Majodrity of applications require the ceramic to be impervious, porous forms can also be made on order. Industrial alumina ceramic crucible is used for testing laboratory and a variety of industrial analysis.We can supply 99% and 99.5% alumina ceramic crucible and zirocnia ceramic crucible according to customer's drawings, samples and performance requirement. Alumina ceramic crucibles include: 1.arc alumina crucible 2.square alumina crucible 3.rectangle alumina ceramic crucible 4.columnceramic crucible 5.other shaped alumina ceramic crucible

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Innovacera manufactures custom and standard ceramic reflector designs for flash lamps, continuous-wave lasers, diode-pumped lasers, and cosmetic surgery markets. Ceramic Reflector is made by high purity porous alumina ceramic of 99% Al2O3 content, used extensively for long-life laser reflectors. This material is sintered at high temperatures to achieve a controlled porosity.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina ceramic (Aluminum Oxide or Al2O3) is an excellent electrical insulator and one of the most widely used advanced ceramic materials. In addition, it is extremely resistant to wear and corrosion and is an industrial ceramic that can only be formed by diamond grinding. The melting point is very high at 2,072°C, and it is very hard. Alumina components can be widely used in electronics, pump components and automotive sensors.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina cearmic bar is used when conditions exclude the use of metal, either for chemical reasons or because of excessive temperatures.Their main applications are between 1000 and 1800°C. They may be in directly contact with the medium or may be used as a gas-tight inner sheath to separate the thermocouple from the actual metal protection tube. Ceramic tubes should be mounted in a hanging position above 1200°C to prevent distortion or fracture due to bending stresses. Evenhair-line cracks can lead to contamination of the thermocouple resulting in drift or failure. High purity ceramic strip provide a broad range of engineering properties: High Temperature-Superior Strength-Corrosion Resistance-Thermal & Electrical Insulation along with other specialized characteristics. -Precision Close, Tight Tolerances, -Ceramic Bar & Ceramic Strip machined to customer specifications-Prototype to Production-Intricate ceramic machining -Alumina is widely used in automotive,petro-chemical

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

INNOVACERA provides a variety of thermal analysis crucible that can be used as sample containers for thermal analysis measurements. The crucible is used as a container for samples during thermal analysis measurements.They guarantee that the sensor will not be contaminated by the measurement.The type of crucible used for the measurement may have a great influence on the quality of the results obtained, as well as on the important characteristics of the DSC measurement unit.Taking relevant factors into account before making a measurement often saves time in interpreting the curve later. TGA Crucible Features: Large volume – increases the sensitivity Purity – elimiates interaction between the sample and the crucible Material – guarantees high form stability Flatness – ensures perfect thermal contact High temperature resistance- Standard TGA crucible are used up to 1600 °C and are available for different sample volumes.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina, also known as Aluminum Oxide, is a hard wearing advanced technical ceramic material frequently used in a wide variety of industrial applications. Once fired and sintered, it can only be machined using diamond-grinding methods. It features high hardness and wear resistance, low erosion levels, high temperature resistance, corrosion resistance, and bioinertness.Additionally, it can be highly polished, making it useful for a wide range of applications. Properties: 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5. High mechanical strength 6. High compressive strength 7. High hardness

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina, also known as Aluminum Oxide, is a hard wearing advanced technical ceramic material frequently used in a wide variety of industrial applications. Once fired and sintered, it can only be machined using diamond-grinding methods. It features high hardness and wear resistance, low erosion levels, high temperature resistance, corrosion resistance, and bioinertness.Additionally, it can be highly polished, making it useful for a wide range of applications. Properties: 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5. High mechanical strength 6. High compressive strength 7. High hardness

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina, also known as Aluminum Oxide, is a hard wearing advanced technical ceramic material frequently used in a wide variety of industrial applications. Once fired and sintered, it can only be machined using diamond-grinding methods. It features high hardness and wear resistance, low erosion levels, high temperature resistance, corrosion resistance, and bioinertness.Additionally, it can be highly polished, making it useful for a wide range of applications. Properties: 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5. High mechanical strength 6. High compressive strength 7. High hardness

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminum Oxide Ceramic is wildely used in many fields including mechanical, electronics, electrical, semiconductor, automotive,textile, etc. For the good propertities, more and more customers choose Alumina ceramic materials for their applications. Alumina Ceramic can be made to Ceramic Nozzles, Ceramic Sprayers Cyclones, Ceramic Linings, Milling Systems, Ceramic Thread guides, etc.Customized designs are very often to be made. Alumina Ceramic Properties: 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5.High mechanical strength 6. High compressive strength 7. High hardness

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminum Oxide Ceramic is wildely used in many fields including mechanical, electronics, electrical, semiconductor, automotive,textile, etc. For the good propertities, more and more customers choose Alumina ceramic materials for their applications. Alumina Ceramic can be made to Ceramic Nozzles, Ceramic Sprayers Cyclones, Ceramic Linings, Milling Systems, Ceramic Thread guides, etc.Customized designs are very often to be made. Alumina Ceramic Properties: 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5.High mechanical strength 6. High compressive strength 7. High hardness

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The Aluminum oxide (Al2o3) 96% ceramic plates are widely used in thick-film circuit of electronics industry. Large scale integrated circuit,power hytrid IC,semiconductor package,pieced -film reistor, network,resistor, focusing potentiometer etc.According to the demands of customers,our company can manufacture products of special types and specifications. Alumina ceramic substrate / plate specification: > 10x10x1mm, 20x20x2mm, 40x40x8mm, 100x60x8mm, 150x150x12.5mm, 200x200x25mm etc. > The thickness of ceramic plate ranges from 0.25 to 1.0mm Can be made according to your requirements.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The Aluminum oxide (Al2o3) 96% ceramic plates are widely used in thick-film circuit of electronics industry. Large scale integrated circuit,power hytrid IC,semiconductor package,pieced -film reistor, network,resistor, focusing potentiometer etc.According to the demands of customers,our company can manufacture products of special types and specifications. Alumina ceramic substrate / plate specification: > 10x10x1mm, 20x20x2mm, 40x40x8mm, 100x60x8mm, 150x150x12.5mm, 200x200x25mm etc. > The thickness of ceramic plate ranges from 0.25 to 1.0mm Can be made according to your requirements.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

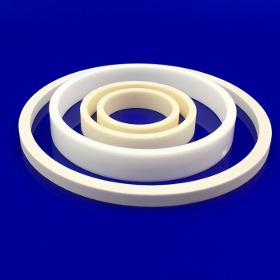

Aluminium Oxide, Al2O3 is a major engineering material. It offers a combination of good mechanical properties and electrical properties leading to a wide range of applications. Alumina can be produced in a range of purities with additives designed to enhance properties. A wide variety of ceramic processing methods can be applied including machining or net shape forming to produce a wide variety of sizes and shapes of component. In addition it can be readily joined to metals or other ceramics using metallising and brazing techniques. Alumina based ceramics are by far the largest range of advanced ceramics made by INNOVACERA. Due to the important combination of properties, we have thoroughly researched the behaviour and characteristics of our Alumina products to give you the best possible component. Typical Alumina characteristics include: Good strength and stiffness Good hardness and wear resistance Good corrosion resistance Good thermal stability Excellent dielectric properties

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminium Oxide, Al2O3 is a major engineering material. It offers a combination of good mechanical properties and electrical properties leading to a wide range of applications. Alumina can be produced in a range of purities with additives designed to enhance properties. A wide variety of ceramic processing methods can be applied including machining or net shape forming to produce a wide variety of sizes and shapes of component. In addition it can be readily joined to metals or other ceramics using metallising and brazing techniques. Alumina based ceramics are by far the largest range of advanced ceramics made by INNOVACERA. Due to the important combination of properties, we have thoroughly researched the behaviour and characteristics of our Alumina products to give you the best possible component. Typical Alumina characteristics include: Good strength and stiffness Good hardness and wear resistance Good corrosion resistance Good thermal stability Excellent dielectric properties

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Innovacera ceramic metering pump is widely used for many famous brand filing machines. We can make customized shapes and sizes of the ceramic filling pump according to clients’ design requests. Product size for reference: Similar Series Products Min Filling Volume: 0.5 ml Similar Series Products Max Filling Volume: 1000 ml Filling accuracy : <=0.5% Product Application: Applicable in quantitative subpackage with high level of hygiene requirement like injection oral liquid etc. Widely applied to pharmaceutical equipment of famous enterprises BOSCH, B+S, IMA, GROENINGER, INOVA company and Trucking Technology, Miaxis, Qianshan, etc.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Porous ceramic tubes are composed by the distributed evenly open pores which is interconnected by shape like arch , when the fluid through these pores,the suspended matter, colloidal particles, organic molecules are trapped, adsorbed inside the micropores,then track to achieve the purification and filtration homogenizing effect. The porous ceramic has the advatage with high strength, wear resistance, high temperature, corrosion, pollution, porosity distribution, long service life and easy to regenerate, which is particularly suitable for a variety of gas, liquid filtration and fluidized process. * Good electrical insulation * High dimensional tolerances * Excellent corrosion resistance * Very high working temperatures * Excellent thermal shock properties

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Product Specification: Application: Used for 936 soldering station Voltage: 24VAC Heating Resistance: 3.0±0.3Ω (23℃±2℃) Dimension: L60*φ3.8mm Electrode: Welding 4 nickel wires on the surface

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic Pellet Igniter Information Ceramic Boiler Ignition Igniter surface can reach a permanent working temperature above 900℃;Since air can through and around inside and outside of the heater tube. Heat can be transferred from both inside and outside of ther heater element. Igniting wood chips, firewood, coal bricks or other biomass fuel. Specification: Voltage: 120V / 230V Power: 150W / 170W / 200W / 230W Tube Size: OD10.5 × ID6.5 × L78 mm Supporting Socket: NO.7 Lead wire: 300mm / 400mm / 500mm / 900mm (Customized is accept) Range of temperature: 800~1100 °C Alumina Pellet Igniter Advantages 1) Higher temperature, about twice of traditional metal sheathed heater; 2) Shorter ignition time, about 60~90 seconds 3) Electrically insulated with no exposed electric contacts 4) Wear and corrosion resistance 5) Long life time 6) Easy to install and replace 7) Long-lasting (non-aging). Tested to 100,000 cycles. 8) 800~1100°C at steady-state temperature.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina ceramic is a kind of ceramic material with a-al2o3 as the main crystal phase, because of its own high melting point, high hardness, heat resistance, corrosion resistance, and electrical insulation characteristics, it can be used in more stringent conditions. Alumina ceramics, with low price and mature production process, is one of the largest and most widely used ceramic materials, mainly used in the field of cutting tools, wear-resistant parts, and bioceramics. In addition, it is also widely used in energy, aerospace, chemical electronics, and other aspects. Especially 95% alumina and 99% aluminas, whether in structural ceramics or electronic ceramics are one of the most widely used ceramic materials. .Purity:92%,96% and 99.7% .Good mechanical strength .Excellent electrical insulation .High-frequency loss .Good thermal conductivity .Heat,wear and corrosion resistance Alumina is the best-known advanced ceramic material, is widely used in automotive,petro-chemical

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina, also known as Aluminum Oxide, is a hard wearing advanced technical ceramic material frequently used in a wide variety of industrial applications. Once fired and sintered, it can only be machined using diamond-grinding methods. It features high hardness and wear resistance, low erosion levels, high temperature resistance, corrosion resistance, and bioinertness.Additionally, it can be highly polished, making it useful for a wide range of applications. Properties: 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5. High mechanical strength 6. High compressive strength 7. High hardness

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Product Specification Application: Mainly applied to the electronic soldering iron Voltage: 110VAC Heating Resistance: 37Ω±15% Dimension: L80*φ5.0mm Electrode: Welding 2 nickel wires on the surface

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Electric 12V 13V Alumina Ceramic Heating Element Heater Rod for Oxygen Sensor Advantages Ceramic Heater for Oxygen senster is used for heating oxygen sensors that detect the exhaust gas of vehicles and is equipped to most of automobile gasoline engines. Because the temperature can be rapidly raised, it is possible to activate the sensor immediately after the engine start which provides useful feedback to reduce emissions. 1.Based material: a.white alumina ceramic b.the content of alumina is no less than 95%. c.the tungsten slurry is printed on the ceramic tape, laminated by hot pressing, and thensintered under the protection of a hydrogen atmosphere at 1650 ° C 2.Ni-wires:N6 Ni-wires with 0.6mm diameter 3.Brazing material: siliver-copper braging alloy

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Technical ceramics are favoured in a wide range of electronics and engineering applications for their chemical and mechanical properties. Compared to metals, they are stronger in compression, especially at higher temperatures. Ceramics have a good thermal stability (i.e. a low coefficient of thermal expansion) and good thermal and electrical resistance. They are also hard, and have excellent dimensional stability. Al2O3 Properties: Excellent electrical insulation Relatively low strength and fracture toughness Resistance to wear and corrosive Excellent thermal stability Resistance to high temperatures High electrical resistivity Good chemical stability High corrosion resistance

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic crucible is the use of high purity powder, trace elements added, from the phase structure and microstructure of modified production.A smelting vessel. Products are aluminum oxide crucible and fully stabilized zirconia porous crucible, the former is mainly used for smelting and laboratory Firing other high melting point material, which is mainly used for the melting temperature with Pt,Rh, Au and other precious metal. Series: •Alumina ceramic crucible •Zirconia ceramic crucible •Conical or curved alumina ceramic crucibles •Cylindrical alumina ceramic crucibles •Rectangular crucibles •Special shaped crucibles •Alumina saggers Alumina ceramic crucible specifications: 5ml 10ml 15ml 20ml 25ml 30ml 50ml 100ml 150ml 200ml 250ml. Applications: >Precious Metal Analysis >Mining Laboratory >Laboratory Testing >Mineral Assaying >Fire Assaying >Gold Assaying

Request for a quoteResults for

Alumina - Import exportNumber of results

78 ProductsCountries

Company type