- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automation of presses

Results for

Automation of presses - Import export

LVD

Belgium

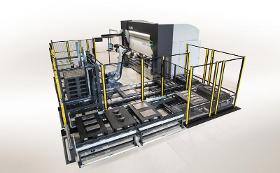

Ulti-Form takes automated bending a step forward with a ToolCell-inspired automated tool changing press brake using a built-in tooling warehouse and equipped with Easy-Form® Laser adaptive bending technology. Programming for both the press brake and robot is handled offline with no robot teaching needed. An auto-adaptive robot gripper designed by LVD automatically adjusts to the workpiece size, allowing different part geometries to be processed without a gripper change. KEY FEATURES Automated tool changer press brake reduces setup time Easy-Form® Laser adaptive bending technology ensures part accuracy KUKA robot and press brake work in synergy to minimize changeover time Programming is handled completely offline, no robot teaching Auto-adapting, universal gripper handles part sizes from 50 x 100 mm up to 1200 x 800 mm High productivity in a compact space, including three input pallets and output zone for up to 10 pallets Automated pallet dispenser and conveyor

Request for a quote

LVD

Belgium

HEAVY-DUTY BENDING IN TANDEM / TRIDEM OR QUADEM PPEB-H custom press brakes offer versatility for heavy-duty bending of L, XL and XXL plate parts. Combine two, three or four PPEB-H press brakes of similar or dissimilar tonnage in a synchronized configuration for maximum productivity and flexibility. When two press brakes are used in tandem, both machines are controlled using one CNC control. For added flexibility, each machine in the tandem can also be used independently. These custom-built machines uniquely meet your heavy-duty bending needs with a choice of configurable options and automation possibilities. KEY FEATURES Two press brakes of similar or dissimilar tonnage working as a synchronized tandem Three or four brakes of similar tonnage working as a synchronized system Synchronized operation of machines with single CNC control PRODUCTIVITY-ENHANCING OPTIONS CADMAN-B programming software Configurable options at point of order, including open height, stroke

Request for a quote

LVD

Belgium

The PPEB-H Series is the choice for heavy bending. These robust, heavy-duty press brakes are custom built for the application. Numerous configurable machine selections and automation options make each PPEB-H press brake a complete, customized solution. LVD’s intelligent bend database optimizes bending parameters for efficient, accurate bending. An intuitive touch screen control reduces the time it takes to go from art to formed part. KEY FEATURES Multiple operating modes ensure optimized ‘Art to Part’ times TOUCH-B touch screen graphical user interface control is intuitive and simple to use Bending parameters automatically controlled by LVD's unique 'intelligent' learning database 2D & 3D color graphics simulate part creation and display material handling sequencing CNC crowning V-axis standard for all models Enhanced Energy Reduction System (ERS) (selected models) Turbo hydraulics (standard) PERFORMANCE-ENHANCING OPTIONS CADMAN-B programming software

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Automation of presses - Import exportNumber of results

3 ProductsCountries

Company type