- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- batch production

Results for

Batch production - Import export

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines -For automation of machining centres – particularly suitable for batch production Product features: -Extreme accuracy for your machining -The clamping force is generated via the pressure from a hydraulic unit with a hydraulic clamping stroke of up to 4.5 mm -The clamping force is steplessly adjusted by regulating the hydraulic pressure on the hydraulic unit. A hand crank is provided for coarse adjustment of the clamping range -The spindle contains a single-acting hydraulic piston and an additional Belleville spring assembly

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines -For automation of machining centres – particularly suitable for batch production -The hydraulic spindle also enables the use of support jaws with which a wide range of unmachined parts, from flame-cut and sawn materials through to complex castings, can be clamped securely and economically. Suitable for materials with a strength of up to approx. 1000 N/mm². Product features: -Extreme accuracy for your machining -The clamping force is generated via the pressure from a hydraulic unit with a hydraulic clamping stroke of up to 4.5 mm -The clamping force is steplessly adjusted by regulating the hydraulic pressure on the hydraulic unit. A hand crank is provided for coarse adjustment of the clamping range -The spindle contains a single-acting hydraulic piston and an additional Belleville spring assembly

Request for a quote

BORNEMANN GMBH

Germany

Individually customised to your production, we produce type holders for the flexible labelling of your products with manufacturer identification, batch number and product code.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

The rapid change system EWS-Varia allows to set-up a modern CNC lathe or a turning milling center – and this flexibly. A tool change will just take 20 seconds, which is an unbeatable argument especially in small batch productions whenever it is about reducing the set-up time and thus increasing the productivity. The advantages, however, are also evident in large batch productions. Preset twin tools lie at the machine, thus significantly reducing the down-times. A further advantage is provided by the variety of adaptations; so the optimal tool clamping can be selected for each operation. The inserts available include: Collet chuck holders Weldon/Whistle Notch Milling arbors Morse tapers Hydro extension Shrink adaptations The most important advantage is certainly created by the easy handling. The inserts can be changed with just one hand without counter pressure by the spindle.

Request for a quote

BORNEMANN GMBH

Germany

Machine type holders, also called type holders, are flexible tools for labelling with figures or letter combinations, batch numbers, production data as well as manufacturer logos. The size of the type holder depends on the surface provided and the labelling required. The machine type holders can also be designed on several lines. As a rule, the clamping is carried out with lateral tensioning screws, but T types and L types are also used. We make this product according to your wishes.

Request for a quote

BORNEMANN GMBH

Germany

Brass types for stamping paper, wood and synthetics. In the pharmaceutical industry brass types are installed in packaging machines with corresponding brass type holders and give the product the labelling. Batch labellings, manufacturer coding and process data are thereby stamped flexibly. If you request changes, the types used can be replaced.

Request for a quote

MOH D.O.O

Slovenia

fast production of individual pieces and small batches under competitive conditions production of medium and large series machining of 5axle components up to 920mm and 800kg machining of 3axle components up to 800 x 2200mm and 1800kg bar machining up to fi 82mm machining from sawn raw materials or castings, turning forgings up to 350mm machining of turbine & compressor components

Request for a quote

WIB SA

Switzerland

Packaging is a very important parameter for the retention of the bearing quality during transport and storage. It is designed to protect the bearings against corrosion, dust, and other pollutants. Apart from that, each unit is labeled and carries all the relevant information concerning the technical and quality features of the bearing. The production batch number is printed on the label and guarantees the traceability of the product, as well as the identification of the manufacturing date. Therefore, it is advisable to unpack the ball bearing only prior to use or assembly.

Request for a quote

MINEBEA INTEC GMBH

Germany

The PC-based software Batch-PMS enables the operation, monitoring and control of batch-oriented and recipe-based production processes. The integrated control system makes it easy to automate weighing and process batch applications. The software Batch-PMS can be easily integrated into existing network and system infrastructures of various industries. It includes modules for process control, production management, recipe management, data management and many further options. Your benefits: — Simple and modular operating concept including multi-user operation — Easy integration into existing network and system infrastructures — Outstanding connectivity — High data safety including integrated backup functionality

Request for a quote

ELKON GMBH

Germany

ELKON Mobil Master-135 JAGUAR Mobile Concrete Batching Plant provides high production capacity along with all the advantages of a mobile concrete batching plant. It has 110 m3/h vibrated concrete production capacity with 4500/3000 l. twin shaft mixer. Besides 4x22,5 m³ capacity square type aggregate bin, 4x20 m³ capacity linear type aggregate bin option is also available which is equipped with axles and tires. ELKON Mobile Master-135 JAGUAR provides the following advantages to its users -Quick and easy installation (only 1-2 days) -Cost-effective transportation (the main unit can be transported by one truck trailer) -Due to the special design, it can be installed on a confined space -Quick and easy jobsite relocation -Low foundation cost (installation is on a flat concrete surface) -Minimizes the concrete transportation cost and environmental impact as well -Easy maintenance and low operating cost -High production performance with optimized automation system

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Online printing of variable data such as batch number, production date, etc. Suitable for installation on blister packaging machines. Can be equipped with different inkjet systems.

Request for a quote

TEMAS GROUP EXPORT PARTNERS

Turkey

Metal&Plastic Engraver: LaserPecker 3 is an optical infrared engraving machine for metal, and plastic. Using a 1064nm pulsed laser, no damage to the material. Ultra-High Precision: 4k precision, perfect picture reproduction. 0,01MM spot, visible details, LaserPecker 3 can help you complete what you what. Dual Red-Light Focus: Say goodbye to cumbersome measurement procedures and double light coincidence to determine the focal length. At the click of a button, you can automatically lift and descend and start engraving in the easiest way possible. Batch Engraving: Achieve batch engraving is not a problem. Use the batch button to engrave again with each click. Batch production of business cards and customized. You can open your own studio at home. No Restrictions: Unlimited time, place, and angle, just plug in and use. 360° rotation, no need to worry about the angle of engraving, bring a power bank, whether you are traveling or traveling, you can carry it with you.

Request for a quote

EC PLAZA

South Korea

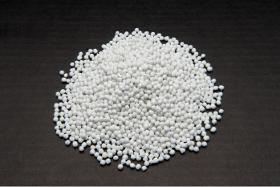

<Product Features> Samil Chemical's white master batch produces white master batch considering the specific gravity and MI by selecting master batch and resin for various Tio2 contents. We are minimizing the defect rate of the product through this production process and promise to supply high quality white master batch. <Product Use> injection molding, Extrusion molding, Brow molding et al. <Company Information> Samil Chemical is developing color master batch and functional master batch. In addition, it is also researching and producing eco-friendly master batch. We also supply various master layouts to domestic and foreign plastic industries at high quality and reasonable prices. We also researching and developing a variety of biodegradable master batches.

Request for a quote

EC PLAZA

South Korea

25note range Silver plated sound blocks with perfect tuning and It contains a note sticker inside. Durable blue case and Color box packaging and 2 mallets included Each of the 25 steel bars is elaborately made.It fits into creating the foundation of your child's music. <Our Company> LUX Music always hangs on to the basic and produces the musical instruments. As the musical instrument manufacturing company for the basic music education, we've always tried our best to make products and satisfy the customer needs. We specialize in the batch production with our manufacturing techniques which have been accumulated for a long time and manufacture all parts in the musical instruments in order to increase product quality. It is supplying its products to Youngchang and Samick, a famous company in Korea. We've exported to many countries including G20 and provided best quality for each country. Also, we've been recognized for our perfect sound quality throughout the world.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

NP-HL Automatic horizontal Labeling machine is designed for the vial bottles and container such as ampoul, blood tubes. It adopts horizontal transmission and horizontal labeling to increase stability and improve labeling efficiency. The label can be printed with the production date, batch number and spray bar code. It can be equipped with inkjet printer to the conveyor belt, which can print the production date, batch number, bar code and other information on the product before or after labeling. Automatic horizontal round bottle labeling machine is suitable for labeling on the circumferential surface of round bottles, can be labeled single label and double label, the spacing between the front and back double standards can be flexibly adjusted, such as gel water round bottle, food round can and other labels, widely used in cosmetics, food, medicine, disinfectant water and other industries

Request for a quote

FERPLAST SNC

Italy

MANUAL NUMERICAL AND ALPHANUMERIC PRICING MACHINES FP-PRZ2 SERIES with 1 or 2 PRINT LINES FOR LABELS 26x16 mm rectangular and wave shape The manual pricing machines are suitable for printing prices, dates, lots, deadlines and codes on adhesive labels. They are particularly suitable for use in the food sector, where it is necessary to specify batches and expirations of the products and wherever it is necessary to label. The pricing machines produce numerical or alphanumeric writings on one or two printing lines and depending on the model the printable characters can be from 8 to 10 per line. The 26x16 labels are available in wave and rectangular format. The most used are white, however it is also possible to request other colors and pre-printed. The printing lines of the pricing machines can be: - numeric: all numbers with dashes and currency symbols (£/€/$). - alphanumeric: all numbers and letters WITHOUT currency symbols.

Request for a quote

FERPLAST SNC

Italy

MANUAL NUMERICAL AND ALPHANUMERIC PRICING MACHINES FP-PRZ SERIES WITH 1 PRINT LINE FOR LABELS 26x12 mm wave The manual pricing machines are suitable for printing prices, dates, lots, deadlines and codes on adhesive labels. They are particularly suitable for use in the food sector, where it is necessary to specify batches and expirations of the products and wherever it is necessary to label. The pricing machines produce numerical or alphanumeric writings on a print line and depending on the model the printable characters can be 8 or 10. The 26x12 labels are available only in wave form and the most used are white, however it is also possible to request other colors and pre-printed. The characters of the pricing machines can be: - numeric: all numbers with dashes and currency symbols (£/€/$). - alphanumeric: all numbers and letters WITHOUT currency symbols

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RPWORLD

China

Urethane casting is a fast and cost-effective method of producing small series from a silicone mold. A silicone mold is made with the help of a prototype which serves as the basis for the duplication process of the original piece. Thanks to the flexibility of the silicone, complex intermeshing geometries can be achieved without demoulding problems. The base material used for the reproductions is a liquid polyurethane resin which with the use of additives can simulate the properties of a wide variety of plastics. Between 15 and 30 parts can be produced depending on the requirements of the material and surface finish. This method is ideal for the production of small batches and prototypes in which the production of expensive injection molding tools is not feasible.

Request for a quote

RPWORLD

China

Urethane casting is a fast and cost-effective method of producing small series from a silicone mold. A silicone mold is made with the help of a prototype which serves as the basis for the duplication process of the original piece. Thanks to the flexibility of the silicone, complex intermeshing geometries can be achieved without demoulding problems. The base material used for the reproductions is a liquid polyurethane resin which with the use of additives can simulate the properties of a wide variety of plastics. Between 15 and 30 parts can be produced depending on the requirements of the material and surface finish. This method is ideal for the production of small batches and prototypes in which the production of expensive injection molding tools is not feasible.

Request for a quote

RPWORLD

China

Urethane casting is a fast and cost-effective method of producing small series from a silicone mold. A silicone mold is made with the help of a prototype which serves as the basis for the duplication process of the original piece. Thanks to the flexibility of the silicone, complex intermeshing geometries can be achieved without demoulding problems. The base material used for the reproductions is a liquid polyurethane resin which with the use of additives can simulate the properties of a wide variety of plastics. Between 15 and 30 parts can be produced depending on the requirements of the material and surface finish. This method is ideal for the production of small batches and prototypes in which the production of expensive injection molding tools is not feasible.

Request for a quote

RPWORLD

China

Urethane casting is a fast and cost-effective method of producing small series from a silicone mold. A silicone mold is made with the help of a prototype which serves as the basis for the duplication process of the original piece. Thanks to the flexibility of the silicone, complex intermeshing geometries can be achieved without demoulding problems. The base material used for the reproductions is a liquid polyurethane resin which with the use of additives can simulate the properties of a wide variety of plastics. Between 15 and 30 parts can be produced depending on the requirements of the material and surface finish. This method is ideal for the production of small batches and prototypes in which the production of expensive injection molding tools is not feasible.

Request for a quote

RPWORLD

China

Urethane casting is a fast and cost-effective method of producing small series from a silicone mold. A silicone mold is made with the help of a prototype which serves as the basis for the duplication process of the original piece. Thanks to the flexibility of the silicone, complex intermeshing geometries can be achieved without demoulding problems. The base material used for the reproductions is a liquid polyurethane resin which with the use of additives can simulate the properties of a wide variety of plastics. Between 15 and 30 parts can be produced depending on the requirements of the material and surface finish. This method is ideal for the production of small batches and prototypes in which the production of expensive injection molding tools is not feasible.

Request for a quote

RPWORLD

China

Urethane casting is a fast and cost-effective method of producing small series from a silicone mold. A silicone mold is made with the help of a prototype which serves as the basis for the duplication process of the original piece. Thanks to the flexibility of the silicone, complex intermeshing geometries can be achieved without demoulding problems. The base material used for the reproductions is a liquid polyurethane resin which with the use of additives can simulate the properties of a wide variety of plastics. Between 15 and 30 parts can be produced depending on the requirements of the material and surface finish. This method is ideal for the production of small batches and prototypes in which the production of expensive injection molding tools is not feasible.

Request for a quote

RPWORLD

China

Urethane casting is a fast and cost-effective method of producing small series from a silicone mold. A silicone mold is made with the help of a prototype which serves as the basis for the duplication process of the original piece. Thanks to the flexibility of the silicone, complex intermeshing geometries can be achieved without demoulding problems. The base material used for the reproductions is a liquid polyurethane resin which with the use of additives can simulate the properties of a wide variety of plastics. Between 15 and 30 parts can be produced depending on the requirements of the material and surface finish. This method is ideal for the production of small batches and prototypes in which the production of expensive injection molding tools is not feasible.

Request for a quote

RPWORLD

China

Urethane casting is a fast and cost-effective method of producing small series from a silicone mold. A silicone mold is made with the help of a prototype which serves as the basis for the duplication process of the original piece. Thanks to the flexibility of the silicone, complex intermeshing geometries can be achieved without demoulding problems. The base material used for the reproductions is a liquid polyurethane resin which with the use of additives can simulate the properties of a wide variety of plastics. Between 15 and 30 parts can be produced depending on the requirements of the material and surface finish. This method is ideal for the production of small batches and prototypes in which the production of expensive injection molding tools is not feasible.

Request for a quote

RPWORLD

China

Urethane casting is a fast and cost-effective method of producing small series from a silicone mold. A silicone mold is made with the help of a prototype which serves as the basis for the duplication process of the original piece. Thanks to the flexibility of the silicone, complex intermeshing geometries can be achieved without demoulding problems. The base material used for the reproductions is a liquid polyurethane resin which with the use of additives can simulate the properties of a wide variety of plastics. Between 15 and 30 parts can be produced depending on the requirements of the material and surface finish. This method is ideal for the production of small batches and prototypes in which the production of expensive injection molding tools is not feasible.

Request for a quote

RPWORLD

China

Urethane casting is a fast and cost-effective method of producing small series from a silicone mold. A silicone mold is made with the help of a prototype which serves as the basis for the duplication process of the original piece. Thanks to the flexibility of the silicone, complex intermeshing geometries can be achieved without demoulding problems. The base material used for the reproductions is a liquid polyurethane resin which with the use of additives can simulate the properties of a wide variety of plastics. Between 15 and 30 parts can be produced depending on the requirements of the material and surface finish. This method is ideal for the production of small batches and prototypes in which the production of expensive injection molding tools is not feasible.

Request for a quote

RPWORLD

China

Urethane casting is a fast and cost-effective method of producing small series from a silicone mold. A silicone mold is made with the help of a prototype which serves as the basis for the duplication process of the original piece. Thanks to the flexibility of the silicone, complex intermeshing geometries can be achieved without demoulding problems. The base material used for the reproductions is a liquid polyurethane resin which with the use of additives can simulate the properties of a wide variety of plastics. Between 15 and 30 parts can be produced depending on the requirements of the material and surface finish. This method is ideal for the production of small batches and prototypes in which the production of expensive injection molding tools is not feasible.

Request for a quote

HWB NUSSWELT GMBH

Germany

Your products deserve the best Nuts and kernels – our new manufacturing technology from Bühler is as diverse as their processing options. From cleaning to roasting, step by step, we can offer our customers all the optimal processes. Whether for continuous production or flexible batch operation – gentle treatment of the nuts and kernels is always our top priority.

Request for a quoteResults for

Batch production - Import exportNumber of results

156 ProductsCountries

Company type

Category

- Milling - steels and metals (25)

- Granules for plastics (8)

- Nuts (8)

- Casting, steel (7)

- Labelling machines (5)

- Concrete mixers (4)

- Gearboxes for vehicles (4)

- Agricultural machines and accessories (3)

- Die casting moulds (3)

- Electronic data processing - microcomputers (3)

- Machine tools - metal machining (3)

- Pharmaceutical industry - machinery and equipment (3)

- Confectionery - machinery and equipment (2)

- Conveyor belts (2)

- Mining and quarrying - machinery and equipment (2)

- Printers - computer (2)

- Stock market (2)

- Abrasives, chemical (1)

- Automation - advisory services (1)

- Bearings, ball (1)