- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automation integrator

Results for

Automation integrator - Import export

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

Analytical shredding systems for QA work are a fundamental preliminary component in the production of substitute fuels. Businesses that buy in their substitute fuel from external suppliers are faced with two key analytical requirements before putting it to use: pollutant analysis and calorific analysis. To ensure the proper handling of these analyses, a sophisticated sampling system is required, meeting the following criteria. Combining over 30 years of experience and the deployment of our proven single-shaft shredder, ERDWICH has developed an automated, integrated system that sets new standards in the areas of sampling and process reliability. Utilise market-leading ERDWICH technology to ensure your success in the substitute fuels sector. To get an idea of what we’re capable of, please see the following Case Studies. Now it’s your turn: we look forward to receiving your project enquiry!

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

Analytical shredding systems for QA work are a fundamental preliminary component in the production of substitute fuels. With primary fuels and finite resources subject to continuous price increases, the significance of substitute fuels continues to rise unabated. For plant operators, this offers first-class potential and attractive prospects for the future. Businesses that buy in their substitute fuel from external suppliers are faced with two key analytical requirements before putting it to use: pollutant analysis and calorific analysis. To ensure the proper handling of these analyses, a sophisticated sampling system is required. System criteria: To satisfy these requirements while ensuring optimum process reliability, you need a partner who possesses long-standing expertise and manufacturing proficiency.ERDWICH is that partner. Combining over 30 years of experience and the deployment of our proven single-shaft shredder, we have developed an automated, integrated system that...

Request for a quote

KAUP GMBH & CO KG

Germany

Attachments from KAUP are not only "The helping hands of your forklift truck". They can also be "the helping hands of your automated guided vehicle", significantly expanding the application possibilities of the innovative automated guided vehicles (AGVs). Whether integrated sideshift, bale clamp or telescopic forks: a wide variety of attachments from the KAUP product range can be integrated into AGVs. It does not matter whether the attachment is electronically or hydraulically operated. As with forklift trucks, KAUP also works with all manufacturers of automated guided vehicles.

Request for a quote

CRYOSNOW GMBH

Germany

• Control cabinet with process control, inspection and monitoring for automated applications • Integrated control and safety components • Simple, ergonomic operation • For use with stationary CO2 tank (or bundles) • Modular construction, design according to customer requirements

Request for a quote

MINEBEA INTEC GMBH

Germany

The Dymond DSV Sideshooter provides reliable detection of foreign objects in upright tall packaging. The compact, hygienic design, interfaces and reliable image processing at high speeds allow for efficient integration into automated production processes.

Request for a quote

MINEBEA INTEC GMBH

Germany

The Dymond D side shooters offer reliable detection of foreign objects in tall, upright packaging. The compact hygienic design, interfaces and reliable image processing at high speeds allow for efficient integration into automated production processes. Reliable inspection with a high throughput Maximum safety through multi-sided radioscopy opens up new possibilities in product design Seamless integration and installation Quick and easy cleaning thanks to the hygienic design Industry 4.0 ready

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The perfect thermoformer for packing your sliced products Whatever you slice – wePACK: Right from the start, the development of the wePACK was focused intently on the requirements of our customers. The result is a packaging machine which is consistently geared to slicing applications and which delivers maximum output, as well as ease of operation and servicing. Thanks to its hygienic design and a high level of automation, the wePACK guarantees maximum food safety. From product preparation to quality checked primary packaging, we offer everything from a single source. This unique situation takes the integration of slicers, automation, packaging and end-of-line equipment to a new level. Weber combines strong single components to even stronger complete line solutions. The boundaries between individual components disappear, so that the complete slicing line merges into one unit. NEW: Optimized software for the integration of infeeding systems

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

By using an array of sophisticated sound sensors, the SV600 can be mounted close to any equipment or asset, to any area of the production line, or where human access is restricted or dangerous to ensure you can monitor the most important parts of your facility without interruption. As a fixed, automated solution, the SV600 integrates with your process and eliminates the need for lengthy fault-finding processes such as soapy water tests, when used as part of your product leak testing process. By continuously monitoring your environment, you can quickly detect and fix air leaks – reducing your consumption of compressed air and energy to help save your facility money. Key Features: High-end 24/7 acoustic monitoring 64-Digital MEMS microphones placed in a Sunflower Array Integrated visual light camera Powerful processor for onboard real time processing Sound classification Frequency filtering dB values and sound intensity mapping Event triggering

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

▪ Hygienic design for food, cosmetic and pharmaceutical applications ▪ Easy integration into automated processes due to compact design ▪ Length and weight savings compared to existing pumps ▪ Short cycle times ▪ Non-destructive dosing of solid containing materials with diameter of up to 20 mm ▪ Volumetric dosing and filling, regardless of viscosity ▪ For low to high viscosity materials ▪ Long service life even with abrasive and shear sensitive materials ▪ Continuous dosing, pulsation free ▪ Precise filling with high repeatability ▪ Linear relation between dosing volume and rotational speed ▪ Programmable suck-back prevents dripping or stringing of product ▪ FDA compliant elastomers ▪ Wetted components are autoclavable ▪ Stainless steel ▪ Optional flushing connection for optimum results with CIP ▪ Easy cleaning and maintenance due to quick assembly and disassembly options

Request for a quote

LUTZ PUMPEN GMBH

Germany

The MEMDOS LP motor-driven diaphragm dosing pump is the ideal choice for applications where the pump needs to be integrated into control systems or control loops. A version with an Ethernet-based MODBUS interface is available specifically for integration into sophisticated automation networks, enabling seamless communication and control. Equipped with a robust plunger drive and the option of manual or automatic capacity adjustment, the MEMDOS LP reliably and precisely doses various media such as acids, alkalis, precipitants and flocculants. This flexibility and precision make it a reliable component in various industrial processes. The MEMDOS LP is also available with a double diaphragm system on request, which ensures increased safety and reliability.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Finishing with bristle brushes requires maximum precision for perfect surface finish and shape accuracy. As the exclusive European partner of Dedeco, Tyrolit offers high-quality, universal radial bristle brushes for light deburring, finishing, polishing, and removing lacquer, paint, and rust. The range includes products for angle grinders, straight grinders, and floor stand grinders, and can also be integrated into automated systems or robots. Available in grit sizes from 36 to 2000, these brushes cover aggressive machining to fine grinding. The flexible bristles adapt perfectly to contours, crevices, corners, and straight surfaces, ensuring excellent results. They guarantee fast, consistent finishing, long service life, and minimal dust and heat development. Different bristle orientations provide adaptability or aggression depending on the application.

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

Kendrion Kuhnke Automation relies on CODESYS as a software platform for a wide variety of applications in the automation industry. For all Kuhnke platforms, this software is available as release CODESYS V3. The IEC 61131-3 programming system offers IEC 61131-3 editors (FBD, LD, IL, ST, SFC), comprehensive debugging and online functions to optimise the application code, as well as fieldbus configurators and editors to generate visualisations. Single and multi-axis motion control all the way to the writing of curves can be projected within the well-known IEC 61131-3 development platform together with all related logic applications. Summing it up it can be said that the tool offers the user an integrated solution to support him in his everyday work and is tailored to offer real-life support to accomplish his tasks. ; EC 61131-3 programming tool for industrial control and automation technology; Integrated visualisation editor; Numerous security features (source code, communication, ...)

Request for a quote

MINEBEA INTEC GMBH

Germany

The Dymond S side shooters offer reliable detection of foreign objects in tall, upright packaging. The compact hygienic design, interfaces and reliable image processing at high speeds allow for efficient integration into automated production processes. Reliable inspection with a high throughput Maximum safety through multi-sided radioscopy opens up new possibilities in product design Seamless integration and installation Quick and easy cleaning thanks to the hygienic design Industry 4.0 ready

Request for a quote

IMS - INTEGRATED MECHANIZATION SOLUTIONS BV

Netherlands

Precision alignment and process technology for the assembly of small products down to micrometer accuracy. CTO technology for assembling small products in a clean room environment - where precision is the key. Modular workstations can be used as standalone operating platforms, integrated into semi-automated platforms, or scaled up for fully automated production lines producing up to 10m products/year.

Request for a quote

IMS - INTEGRATED MECHANIZATION SOLUTIONS BV

Netherlands

Precision alignment and process technology for the assembly of small products down to micrometer accuracy. CTO technology for assembling small products in a clean room environment - where precision is the key. Modular workstations can be used as standalone operating platforms, integrated into semi-automated platforms, or scaled up for fully automated production lines producing up to 10m products/year.

Request for a quote

IMS - INTEGRATED MECHANIZATION SOLUTIONS BV

Netherlands

Precision alignment and process technology for the assembly of small products down to micrometer accuracy. CTO technology for assembling small products in a clean room environment - where precision is the key. Modular workstations can be used as standalone operating platforms, integrated into semi-automated platforms, or scaled up for fully automated production lines producing up to 10m products/year.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

STRONG. SOLID. LONG-TERM ACCURACY - Travelling column machining centers with modular equipment variants and particularly high performance. STABILITY, YOU CAN FEEL! - Combination of extremely rigid & stable machine - High stability during machining - Extremely high rigidity sets new standards for moving column machining centers LONG-TERM ACCURACY - Long-term machining with consistent product quality - High precision even after years of use CUSTOMIZED MACHINE SOLUTIONS - Joint development of your milling strategy - from development to commissioning - Expertise from individual to series production, also automated 24/7 - Possibility of integrated automation FLEXIBILITY THAT INSPIRES! - Wide range of options | rotary table, magnetic table, swivel table, additional magazine, partition wall, etc. - From heavy-duty machining to high-precision finishing of a wide range of materials

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WALTER UHL TECHNISCHE MIKROSKOPIE GMBH & CO. KG

Germany

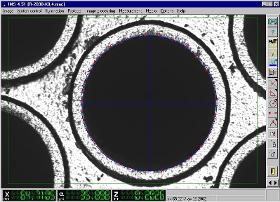

The efficient fully-automated and highly integrated measuring software for measuring of series parts. Usable for recurring measuring tasks up to integration in CIM production plants. IMS is available in english. automatic measuring functions and combinations intuitively usable tools are available for automatic edge detection and geometrical combination sophisticated macro language with macro editor flexible and efficient macro-language with teach-in functionality for complete control of the measuring sequence with variables, sub-routines, database linking and text print-out comfortable macro editor with breakpoints comfortable macro editor with breakpoints, variable inspection and online help

Request for a quote

LOUISON INDUSTRIES

France

As a state-of-the-art plastic injection moulding company, we guarantee the highest standards of quality. The thermoplastic granules, with a diameter of 2 to 3 mm, are carefully sucked into a hopper and then heated to high temperature. The molten, malleable material is then injected into the mould, selected according to your specifications. Our high-precision injection moulding machines apply high pressure to allow the plastic to spread evenly in the mould, giving it its final shape. In just a few seconds, the part cools and solidifies, ready to be ejected into a recovery bin. Integrating an automated system into our plastic injection process enables us to minimise costs - Weight: Up to 400 g - Texture: Any texture on request - Composition: Polyester, Polyamide, Polypropylene....

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The GEMÜ 651 2/2-way diaphragm valve has a stainless steel piston actuator and is pneumatically operated. The valve is designed for use in a sterile environment. The valve has a fully integrated automation module and an internal air supply. Normally closed (NC) and Normally open (NO) control functions are available. The automation module is available in two versions. —Reduced planning and cabling time —Integrated air ports —Speed-AP function for fast mounting and initialisation —Optional flow direction and installation position

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

— Minimize operator intervention with a fully automated and integrated solution — Capture data from inaccessible or dangerous areas to keep your team safe — Monitor sound signature changes in real-time to prevent unscheduled maintenance Visualize the unheard and unseen with the power of acoustic imaging. The SV600 Fixed Acoustic Imager enables users to continuously detect, locate and visualize air and gas leaks or changes in sound signatures before they become costly problems.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

ThermoView TV40 is a high-performance industrial thermal imaging system for fixed installation designed for factory automation applications. It integrates a visible-light camera and software for temperature control, monitoring, and data archiving. • Wide temperature range: -10 to 1200 °C (14 to 2192 °F) • Rugged aluminum housing, IP67 (NEMA 4) • Ambient temperatures to 200 °C (392 °F) with high-temperature enclosure • Air purge and accessories available • IR-Fusion technology: simultaneous thermal and visible sighting • Remote motorized focus • 320 x 240 and 640 x 480 focal plane array • 9 or 60 Hz models available • GigE Vision interface • LAN/Ethernet with PoE for communication with the camera provides access to Ethernet, Web server and ThermoView Software • Multiple field interchangeable lens options • 2-year warranty

Request for a quote

BRUKER OPTICS GMBH & CO. KG

Germany

The LUMOS II offers outstanding visual and spectral data quality with full automation of all measurement modes: transmission, reflection and ATR. For FTIR beginners and experts alike, the LUMOS II is the best solution for infrared microscopy. Bruker's exclusive Focal Plane Array (FPA) detector technology allows you to experience detailed imaging at the maximum speed. This allows you to take full advantage of the vast possibilities offered by FT-IR microscopy. The OPUS IR software provides you with assistance whenever you need it and allows you to glide effortlessly through measurement, evaluation and reporting. Your advantages: • Extremely fast FT-IR imaging (FPA) • High spectral quality and resolution • Brilliant visual images and huge field of view • Fully automated FT-IR microscope • Integrated, piezo-controlled ATR crystal • Software supported measurement and evaluation • Automatic measurement in transmission, reflection and ATR

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

IAI Industrial Robots is one of the leading manufacturers of electric actuators and industrial robots. In addition to catalogue products, we also offer customised products and special developments. Actuators from IAI can be easily connected to automation applications and integrated into production lines in all industries. The controllers can be connected to the higher-level controller via digital I/Os or via fieldbus systems such as Profinet, Profibus, CC-Link, DeviceNet, EtherCat, EtherNet, Modbus and many more.

Request for a quote

ALKE MACHINERY ENGINEERING

Turkey

We produce automated integrated production lines of muesli bar, snack bar, fruit bar, vegetable bar, nut bar, granola bar. The lines include automated groups: supply of ingredients, cooking, forming, cooling, cutting, chocolate coating, decorator, packaging. Depending on the application, we provide automated and semi-automated lines with different performance. Completion with automatic feed systems is possible.

Request for a quote

STEROS GPA INNOVATIVE, S.L.

Spain

Advanced work cell for all kinds of industries requiring full automation —or a multi-level DLyte process automation— to integrate surface finishing in mass production lines. This machinery is especially aimed at large manufacturing companies needing to optimize or reduce their production times, thus achieving cost savings and a quick, efficient return on investment. DLyte PRO500 Automated Cell is formed by a polishing cell —that is, one or two units of DLyte PRO500, the most powerful, advanced and versatile dry electropolishing machine on the market— and a loading mechanism which in turn comprises a robotic arm and a rotating module. Besides polishing several metal pieces simultaneously, DLyte PRO500 Automated Cell automates the process of loading and unloading the holders into and from the machine itself. The system can be configurated with one or two DLyte PRO500, to make possible high-output and multi-step processes in an extremely compact design. It can hold up to 64 holders.

Request for a quote

LVD

Belgium

The Dyna-Cell features the high-speed Dyna-Press Pro electric press brake coupled with an industrial robot. The compact, integrated unit automates the bending of small- to medium-sized parts in varying batch sizes at speeds of up to 25 mm per seconds. Dyna-Cell offers maximum bending productivity in a compact footprint of 5 m x 5 m. KEY FEATURES Optimum cost-benefit ratio Fast, electric-drive press brake Lightweight Kuka industrial robot Start final production after <10 minutes CAM and <10 minutes setup Unique gripper that fits all part sizes from 30 mm x 100 mm up to 350 mm x 500 mm Space for two input pallets, two unloading pallets or boxes (Euro pallet size) Intuitive 15” Touch-B touch screen control Fully integrated with LVD's CADMAN® software suite Unmanned or manned operation PERFORMANCE-ENHANCING OPTIONS Easy-Form® Laser system CADMAN-B programming software W-style or universal tooling MODELS

Request for a quote

LVD

Belgium

The ToolCell makes any bending application easier and more productive using revolutionary bending automation technology that minimizes setups, is fast and highly reliable. An integrated automated tool changing system stores a library of top and bottom tooling. All tools are held within the machine and automatically changed as the job requires – significantly minimizing tool changeover time for better bending productivity. LVD’s patented Easy-Form® Laser in-process angle monitoring and correction technology ensures the first part is a good part. KEY FEATURES TOUCH-B touch screen graphical user interface control is intuitive and simple to use All tools held within the footprint of the machine Large library of tools: 2 complete lengths of self-seating top tooling (punches) and 5 complete lengths of bottom tooling (Vee dies) Flexible tooling configuration Automated tool loading and unloading Equipped with Easy-Form Laser Precise set-up for every job – No fine adjustment of tool stations

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

The ultrasonic actuators of the SLIMLINE product line are characterized by their extremely slim design and their large variant diversity. These ultrasonic actuator types are available in frequencies of 20, 30, and 35 kHz. A compact console structure, precise guiding systems and variable drive units are a solid basis for repeatable weld results. In combination with Herrmann weld process controls, the system is used for customized integration solutions in automation.

Request for a quoteResults for

Automation integrator - Import exportNumber of results

56 ProductsCountries

Category

- Automation - systems and equipment (4)

- Optical measuring equipment (3)

- Brakes, servo-brakes and accessories (2)

- Laser - cutting and welding machines (2)

- Measurement - Equipment & Instruments (2)

- Metal detectors (2)

- Sensors (2)

- Abrasives, mechanical (1)

- Acoustic equipment, electric - professional sound-engineering (1)

- Active electronic components (1)

- Applicators for adhesives and glues (1)

- Blast cleaning equipment (1)

- Cables, high-voltage (1)

- Confectionery - machinery and equipment (1)

- Conveyor systems (1)

- Dosing pumps (1)

- Electric transformers, converters and rectifiers (1)

- Electrical & Electronic Components (1)

- Electron beam welding - equipment (1)

- Food industry - machinery and equipment (1)