- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sensor systems

Results for

Sensor systems - Import export

MEDEK & SCHÖRNER GMBH

Austria

Special high speed adapted ink jet printer with finely adjustable printhead support for marking bandmarks from one side on the fiber at speeds up to 1150 m/min. The usual arrangement allows bandmarking in line with the ink coating process, providing irradiator units after the ink jet printhead and the ink applicator. In case that no additional UV lamp unit and only the UV lamp of the UV curing unit CCD1-K unit is available, bandmarking has to be done in a separate process (either bandmarking or ink coating). The microprogram of the ink jet printer is specially adapted for ultra high speed bandmarking with automatic control of a constant bandwidth over the full speed range. Bandmark pitch and interband distance for multiple bandmarks (double, triple, etc.) are easily programmable on the computer screen. LD - INK LEVEL SENSOR AND INDICATOR SYSTEM FOR INK TANKS Triggers a warning signal as the ink level drops below minimum.

Request for a quote

MEDEK & SCHÖRNER GMBH

Austria

Automatic synchronization to the line over a 1:6 speed range (requires a 0 V to 10 V signal proportional to the line speed); for lines providing no such control signal a dedicated frequency generator with tachometer wheel and incremental encoder is required. V - AUTOMATIC VISCOSITY CONTROL FOR PRINTING INKS An oscillating sensor causes thinner to be added when the viscosity deviates from a preset value. LD - INK LEVEL SENSOR AND INDICATOR SYSTEM Triggers a warning signal as the ink level drops below minimum. FW - INK FLOW SENSOR AND INDICATOR SYSTEM Triggers a warning signal as the ink flow deviates by an adjustable amount from the preset value. MARKING DRUMS Easily replaceable pairs of marking drums for use as spares for supplied marking drums or for changing the ring spacing or pattern. Standard ring patterns include single or double rings every 17 mm; double rings every 34 mm; one, two, three, or four rings every 60 mm

Request for a quote

IGM ROBOTERSYSTEME AG

Austria

igm gas nozzle searching - Tactile sensor for position detection This tactile sensor is used to determine the workpiece position or its components and individual parts by gauging the surface of the workpiece. In each case, the successional part of the program is shifted according to determined deviations. Sensor shifting may be applied for correction of an arbitrary amount of individual points, entire sections of a welding program or entire programs. Combination with arc seam sensing is feasible. The control system supports shifting, rotating, and tilting of a program, depending on position change. The gas nozzle itself is used as a sensor. This makes it possible - even on complicated workpieces and in confined spaces - to perform the required search steps on the reference surfaces of the workpiece, by which the position of the weld seams is determined. As soon as the gas nozzle gets into contact with the work piece, it is discharged and the robot stops immediately. This...

Request for a quote

IGM ROBOTERSYSTEME AG

Austria

Sensor-controlled bevelling system for automated welding seam preparation of flat steel plates. The stable portal construction including application-oriented design of the cutting head supports all types of upper side or bottom side cuts with sensor-controlled online edge tracking. A laser camera measures the workpiece position and tracks along the upper edge, ensuring the requested land heights with a tolerance of +/- 0.5 mm even compensating heat distortion. The system processes the required bevels, which are defined by simply clicking and inserting the geometry parameters in a CAD drawing of the component, with the specially developed software. Sensor supported systems can be provided with the igm ibs oxy and plasma cutting machine which are optimized for all mechanical and control requirements for chamfering flat sheet metal. This special characteristic was made possible by the development of a parallelogram-like cutting head, on which the cutting torche, movable in two axes,...

Request for a quote

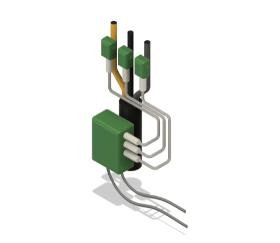

GREENWOOD-POWER

Austria

The temperature sensor system is made for solving a big problem in switchgears. It is modular and can be used in cable compartments of gas insulated switchgears or even in air insulated switchgears, directly on the medium voltage busbars to monitor temperature rises, especially in busbar conjunction points. The system could be delivered with wired cost efficient solutions for low voltage applications or on medium voltage cables or completely galvanic separated with a Power over fiber connection from the base station to the temperature sensors directly attached to the primary busbar.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Sensor systems - Import exportNumber of results

5 ProductsCompany type