- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- api 6a

Results for

Api 6a - Import export

PIRPED INTERNATIONAL

France

Standard: API 6A Dimension : 2 1/16" - 30" Pressure : 2 000 psi-15 000 psi Material : Carbon Steel, Alloy, Stainless Steel, Duplex & Super Duplex and others…

Request for a quote

SPM - SOCIÉTÉ PYRÉNÉENNE DE MÉTALLURGIE

France

SPM has accrued more than 60 years of experience in manufacturing solid metal gaskets for high pressures, high temperatures and corrosive agents applications that comply with API6A, ASME B16-20, EN 12560, and ISO 10423 standards. Our products are certified and approved by the leading international contractors. We feel that a gasket is, above all else, an element of safety. Traceability is guaranteed: Each lot of materials supplied has passed our quality control system (ISO 9001: 2008 and API Spec 6A-0200) and our lots are systematically inspected by PMI-type testing. Standard and special gaskets: Our expertise is focused on the complete manufacturing of standard or special metal axisymmetric gaskets. A large stock of standard gaskets is available. Whatever your needs might be, we have mastered all of the requirements set out by the standards as well as customers’ special needs.

Request for a quote

SPX FLOW EUROPE LTD - THE NETHERLANDS

Netherlands

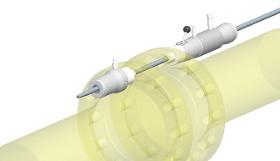

Designed for high performance and reliabilty, our Subsea Pulling System provides the following benefits: Compact Design. Long Piston Stroke. Self Activating collets. Auto-Grab Anchor collet with hydraulic release. Manually releasable Retract collet prevents lock on. High Strength, low rotation wire rope. Anti-Slip surfaces. Operated via a separate Diver Control valve providing precise control for up to four flange pullers. Compact Design Designed to fit ANSI B16.5, MSS SP44, API 6A and most other flange applications dedicated flange hole adaptors. Hydraulic Anchor Collet Release Anchor collet automatically grips wire rope (without hydraulic pressure). Collets can be fully released by applying hydraulic pressure. Auto Advance Collet Release Advance collet fully disengages when the pulling cylinder is fully retracted Manual Retract Collet Release Retract collet can be manually disengaged, allowing the pulling cylinder (including Advance and Retrace collets) to be removed from...

Request for a quote

SPX FLOW EUROPE LTD - THE NETHERLANDS

Netherlands

Designed for high performance and reliability, our Subsea Pulling System provides the following benefits: Compact design Long Piston Stroke - 4" (102mm) 10,000 psi (700 bar) systems Rapid assembly using Quick Release Reaction Nuts High strength threaded bar Anti-Slip surfaces Operated via separate diver control valve providing precise control for up to 4 pullers Compact Design Designed to fit ANSI B16.5, MSS SP44, API 6A and most other flange applications dedicated flange hole adapters. Hydraulic Anchor Collet Release Anchor collet automatically grips wire rope (without hydraulic pressure). Collets can be fully released by applying hydraulic pressure. Auto Advance Collet Release Advance collet fully disengages when the pulling cylinder is fully retracted Manual Retract Collet Release Retract collet can be manually disengaged, allowing the pulling cylinder (including Advance and Retrace collets) to be removed from the wire rope while the rope is installed in the flanges. Also...

Request for a quote

BRODER METALS GROUP LIMTED

United Kingdom

Broder Metals Group stocks Alloy 718 in sizes from 1/2″ (12.7 mm) to 4″ (101.6 mm) backed up by key sizes above this core range. Our stock is bought to API 6A 718, ASTM B637 and NACE and as such meets most application uses for the oil industry to maximise resistance to stress corrosion cracking or treated to give maximum strength and high creep resistance and weldability. Our experience enables us to stock and supply alloy 718 round bar to the full range of the following specifications: API 6A 718 (December 2009) ASTM B637 AMS 5662 AMS 5663 UNS N07718 NACE MR0175 / ISO 15156-3 Broder Metals provide this alloy with our global same day quote, next day dispatch service. All our metals are fully traceable for your confidence, with clear certification delivered electronically or sent with the material as requested. For further information please contact us at ++44 (0)114 232 9241.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TETHYS OIL SUPPLIES & SERVICES

Malta

Designed to boost your well economics, our gate valves meet API PR2 Annex F operational requirements and are built to withstand the harshest onshore production environments. Leveraging on more than 20 years of field experience with the standard Series100 valves, TechnipFMC’s M120plus gate valve design is developed over 4 years of extensive research and development. Detailed finite element analysis led to development of a lighter, more open valve body which enables better access to the seat pockets for easier, quicker assembly and maintenance. TechnipFMC individually qualifies each gate valve size using nitrogen gas even though API Spec 6A permits qualification by scaling one size above and one size below the tested valve. In addition, TechnipFMC imposes additional performance requirements and endurance testing to simulate 25 years of operation in the field. Also available in “adapted for actuator” configuration for M130Plus model.

Request for a quoteResults for

Api 6a - Import exportNumber of results

7 ProductsCountries