With UK supply chains experiencing high pressure due to the effects of the COVID-19 pandemic, Brexit and other factors, many companies have already adopted AI solutions to mitigate these negative effects and increase the resilience of their supply chains.

The DHL Logistics Trends Radar shows a number of AI solutions either currently in use or predicted to be implemented within five years, including cloud and API, big data and analytics, indoor robots and smart labels, all of which are being applied by UK logistics companies in various scenarios.

According to a 2022 SAP survey, 70% of UK businesses plan to adopt the latest technology to try to overcome supply chain challenges.

The automated warehouse and rise of the robots

The UK government’s 2021 AI barometer for transport and logistics lists a number of areas in which AI is being successfully deployed in logistics, notably transport system management, planning, navigation, ‘smart infrastructure’, and ‘Mobility as a Service’ (MaaS). Smart freight management, in which capacity sensors can detect space in a warehouse, car park or container, is widely in use, as is self-driving vehicle technology. One impressive example of the automated warehouse is online supermarket Ocado’s customer fulfilment centre.

And the Port of Tyne - the UK’s first 2050 Maritime Innovation Hub - is currently testing an AI application to predict how weather patterns could impact quayside operations, as well as predictive maintenance technology with smart sensors located on key parts of equipment.

The use of robotic process automation tools is also on the rise. Asendia UK has successfully introduced robotic parcel labelling at its Heathrow automated processing centre, speeding up parcel processing and increasing accuracy.

Additionally, leading supply chain partner Wincanton has invested in a fleet of 48 autonomous mobile robots, enabling it to provide innovative fulfilment solutions such as that for natural remedies company Neal’s Yard, where a blend of robotics and wearable technology has been implemented.

Read on to find out more about the possibilities of these new technologies, and what industry decision-makers need to know about them - both now and in the future.

6 million professional buyers are waiting for you!

Present your product range online to buyers and make sure that your company is visible to the right people. Expand your international internet presence with the leading B2B platform in Europe. With a free profile on europages!

Automation and AI: current and future areas of application in logistics

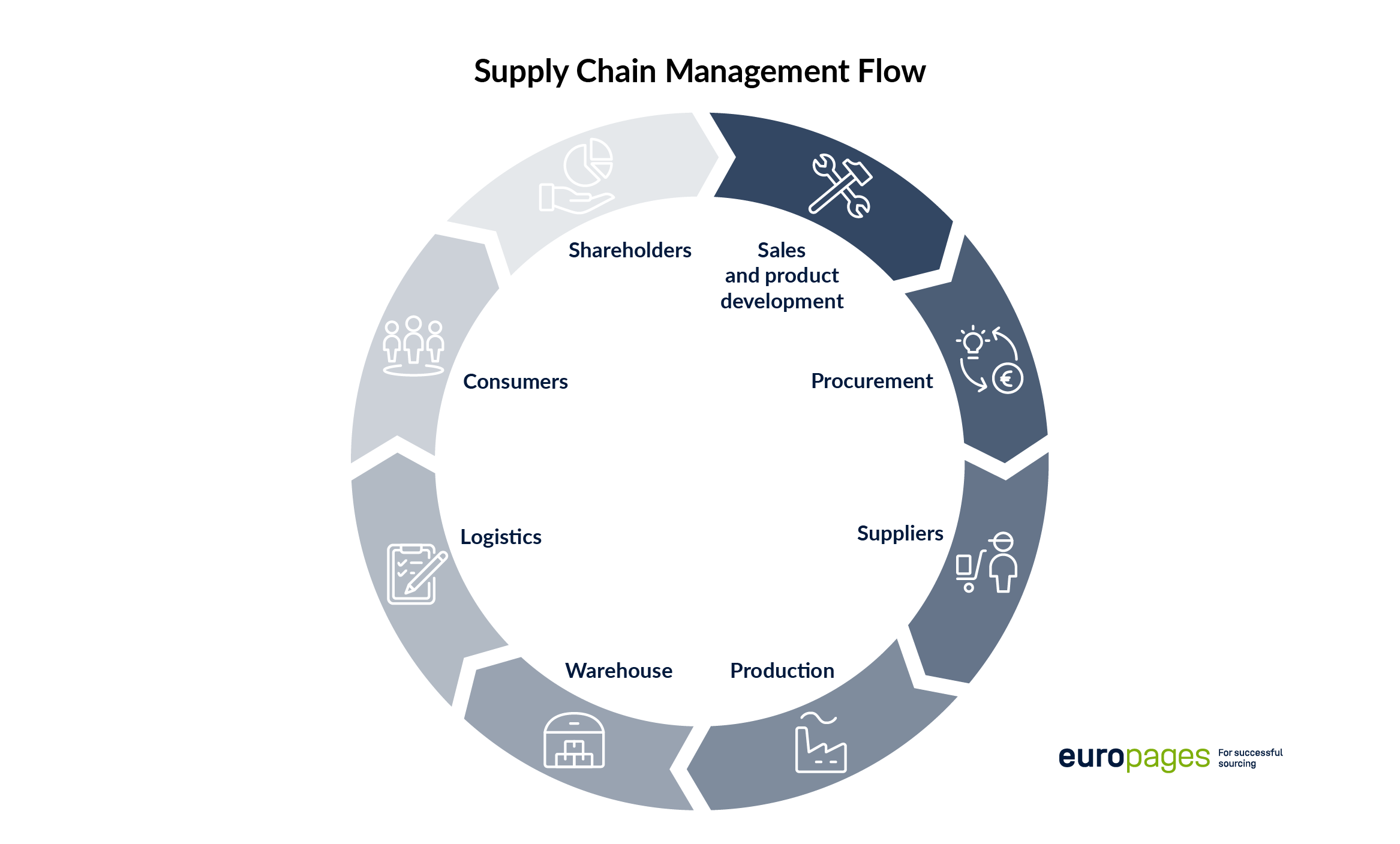

Artificial intelligence displays its greatest strengths in combination with technologies derived from or related to it. These include machine learning and automation in logistics. In combination, many processes can be simplified, controlled, analysed and, for the most part, made independent. Supply chains, transport routes, warehouse logistics, human resources planning – these are just a few of many possible applications.

AI and its related technologies enable companies to deal with current and future challenges more easily and effectively.

Skills shortage: Almost every company knows how difficult it is to recruit and retain qualified staff. The recruitment process and drawing up contracts for new staff consume a lot of resources. Here, AI can save staff time and effort with smart organisation and automation. This begins, for example, with the placement of new goods in the optimal location in the warehouse, ordering supplies, transport tracking, or the early detection of order peaks or failure of technical components (predictive maintenance). Many of these processes can be controlled accurately with digital systems, i.e. automation, with minimal staff deployment. This applies similarly to strategic planning at the management level, because AI systems provide appropriate data and recommendations for action.

Climate protection: Implementing and proving sustainability is not always easy. First of all, this means that logistics processes must be resource-saving and carbon-neutral. It is often difficult to identify where this can be practically implemented in the company. AI and Internet of Things (IoT) sensors can provide valuable information here through data collection and processing. With appropriate systems, the results can be documented and constantly compared in order to find further savings potential in energy, heat or raw material consumption.

Increasing efficiency and resilience: As in the case of climate protection, AI and automation can also perform in other areas of logistics. As mentioned, this applies to optimised warehouse management, but equally to route planning. In this way, the most advantageous routes and means of transport can be determined in order to avoid detours, loss of time and empty runs. This also helps to comply with the legal speed regulations and rest periods for drivers, for example. In addition, it’s always possible to see where a product is currently located along the supply chain.

Possibilities of ChatGPT: This AI-powered software is still so new that concrete use cases in logistics have not yet explicitly emerged. For example, it cannot pull real-time or up-to-date information from supply chains. But when linked to machine learning, it could reach the point where it creates easy-to-read reports based on that data. So, with later versions, it may be possible, if required, to create instant messages when something unforeseen occurs. This should significantly shorten the response time, as the information is received directly in text format by the relevant departments.

A best practice example from logistics

Artificial intelligence helps logistics in many ways. Smart planning, as used by the German software and consulting company Soloplan, is fundamental. For 30 years, it has been offering its forwarding software CarLo as a solution for transport management.

Thanks to AI and machine learning, the tool can now anticipate the behaviour of dispatchers. Among other things, it uses this function to automatically create routes using data compiled from figures based on experience. This relieves dispatchers of one of their most time-consuming tasks.