- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- laser sheet metal cutting

Results for

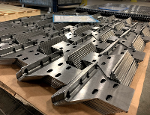

Laser sheet metal cutting - Manufacturer Producer - Germany

GermanyManufacturer/producer

Product recommendations

Turkey

Turkey

Poland

China

-

TEPROSA GMBH

Germany

-

QINHUANGDAO YUANCHEN HARDWARE CO.,LTD.

Germany

-

SCHWARZ SYSTEMS GMBH

Germany

-

LASERTECHNIK WÜNSCH

Germany

-

MECHASYS GMBH

Germany

A page for your business

Can you see this?

Your potential clients will too.

Join us now so you too can be visible on europages

Filters

Results for

Laser sheet metal cutting - Manufacturer Producer - GermanyNumber of results

17 CompaniesCountries

Company type

Category

- Folding - steels and metals (4)

- Industrial sheet metal work (2)

- Laser - cutting and welding machines (2)

- Turning - steels and metals (2)

- Industrial building construction (2)

- Steel & Metal Transformation (2)

- Bending - steels and metals (1)

- Steels and metals - forming and cutting (1)

- Cutting - steels and metals (1)

- Steels and metals - machining (1)

- Machine tools - metal machining (1)

- Shearing - steels and metals (1)

- Automation - systems and equipment (1)

- Containers (1)

- Copper and copper alloys (1)

- Copper and iron hardware and fittings for furniture (1)

- Machine tools - metal shaping (1)

- Scouring - steels and metals (1)