VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Manufacturer/ Producer

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

This method allows extremely fast workpiece cooling. When it is necessary to pack or stack workpieces immediately, VEN DRY COOL modules can be installed in all Venjakob drying equipment at any time. Perfect surface results are guaranteed by the drying technique of these individual machine line solutions.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

A high surface quality results, above all, from long, gentle drying, especially when solvent containing paint systems are used. Production sequences often do not provide sufficient space for buffer storing. Furthermore, the transportation of workpieces generates high costs and implies the risk of damage. To avoid these aspects, Venjakob has developed innovative drying equipment with varying conveyor systems, all of which being based on the convection drying principle. The innovative and uniform cross ventilation of the Muli-level dryer VEN DRY COLLECT yields optimum drying results. If only solvent is used, the lower cost variant with longitudinal ventilation is available as an option.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Newly designed slotted jets arranged throughout the entire operating width guarantee constant flow conditions in the drying compartment. Depending on the coating material, the air is heated via hot water, thermal oil or steam in special heat exchangers. Particularly intensive drying is achieved through the high air speed in the jet channel.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

In this system, high air speed is used for intensive drying. A modular construction enable different dryer lengths, depending on the application. Temperature, air speed as well as supply and exhaust air can be manually set at the dryer. A frequency controlled version is available upon request. Flow meters monitor the exhaust air values and thus the correct function of the drying process.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

With the VEN DRY OIR dryer, the surface quality of lacquered workpieces can be considerably improved while simultaneously reducing the drying times. Premature closure of the surface is effectively prevented by evaporating the surfaces in conjunction with targeted heat application into the paint layer interior. The paint uniformly and quickly dries from inside out. The OIR flat evaporation tunnel in modular design with belt conveyor optimally meets all requirements. The standard equipment comprises three IR radiator modules, each equipped with two radiators and easily accessible through lateral inspection flaps.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Multi-level pallet dryers optimise gentle drying of painted workpieces up to a maximum of 250° C. The hot air guided crosswise to the workpiece transport direction prevents the effects of dust and air draft. Heating medium: Gas, steam, electricity, hot water, oil.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The painted workpieces are stored in trolleys. There are three possibilities for the drying process, depending on the customer's request and type of paint/lacquer. Either directly in the production room, in an existing heated room or in a special trolley channel. Venjakob offers drying concepts with trolleys as well as individual carriages in different versions individually tailored to your requirements. Upon request, we will also automate the loading of the trolley by means of VEN MOVE STACK.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

UV curing paint systems are hardened within seconds by intensive UV radiation. These systems permit short production processes requiring little space. The number of required radiators depends on the throughfeed speed, the type of paint, the quantities applied and the workpiece geometry. Performance optimised UV lamps are used in the VEN DRY UV dryer. These feature emission spectra perfectly matched to the individual paint/lacquer. Mature transformer technology in combination with high-performance UV lamps ensure safe and reliable operation. The new generation of dryers with "SURROUND-UV" technology offers the following advantages:

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

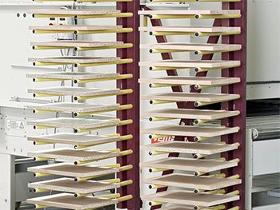

The drying method is based on a hot air-circulating air system, divided into different zones. A well thought-through ventilation system ensures uniform and effective ventilation in all parts of the dryer. The flexible system can be used to dry almost all types of lacquers/paints except for hardening lacquers/paints such as UV and EBC lacquers. The high-performance vertical dryer consists of a defined number of belt pallets. Following lacquer application, the parts move into the dryer and stop on a pallet which subsequently raises. The subsequent pallet is then ready for the infeed of the next workpieces. The dryer is manufactured in modular construction and adapted to the requirements of the customer. Batch length: maximum 6,200 mm Batch width: maximum 1,300 mm Batch height: maximum 50 to 90 mm

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The demands on production processes often change very quickly. VEN DRY VARIO TIME makes it possible to react quickly. The batch is detected by light barriers at the infeed and the dwell time in the dryer is controlled accordingly by the state-of-the-art control system. The special handling technology with sophisticated Venjakob control system exceeds your expectations for a powerful and flexible dryer concept. Loading locations: 38 Operating width: 1,300 mm Pallet length: 5,600 mm Useful length: 5,500 mm Loading per palletmaximum: 100 kg Item heightmaximum: 60 mm

Request for a quoteManufacturer/ Producer

Augsburger Straße 2-6

33378 Rheda-Wiedenbrück - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

FÖHRENBACH GMBH

Germany

The machine structure with solid base plate is extremely compact and stable. All necessary components are integrated in the machine housing: mechanical axes, pneumatic components, control with drive electronics and mounted 12 "touch display. Depending on the desired version, the F-Décor 305 can produce surface patterns like circular grainings, côtes de Genève, engravings or decorative millings on mechanical watch parts. The machine guarantees high precision and high productivity. The F-Decor 305 is delivered ready for connection with either 1 or 2 working spindles.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

For machining technical ceramic componentsTYROLIT offers a comprehensive range of products for machining ceramic components. These include various application-specific bond systems with optimised performance in conjunction with new diamond qualities. Reduced wheel wear High stock removal rate Low grinding forces

Request for a quote

J.D. GECK GMBH

Germany

Use our industrial manufacturing expertise for your products too Electroplated surface finishing The maximum goods window for galvanising, chromeplating and nickelplating is L / W / D 2800x450x1000 mm. Chrome and nickel plating Galvanising (galvanising without passivation; blue galvanising with variable layer thickness and blue passivation; thicklayer passivation with nanosealing) Electrostatic powder coating Maximum load per hook 30 kg workpieces up to 60 kg Maximum workpiece size L / W / H = 3000/800 /1700 mm More information available at https//www.geck.de

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

For CNC machines Metal and resin bond diamond tools with continuous rim for engraving crystal glass and stone materials. For the extremely challenging art of finishing elegant and aesthetic items. Processing can be required for both functional (niches for sliding glass window panes) and decorative reasons. The engravings can have a straight, wavy or aesthetic design. They are carried out using differently shaped and bonded wheels Excellent finishing Long lifetime

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free