FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Manufacturer/ Producer

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Regular rollers prevent belt misalignment and guarantee protection of the belt edges. As the regular rollers only function efficiently when the drum casing is clean, the rollers are equipped and delivered with dirt repellent 60° shore soft rubber. Our regular rollers can be used with both normal and reversing conveyor belts. Mode of operation When the conveyor belt is running straight, the axle through the roller casing forms an angle of 90° to the direction of movement of the belt. When the belt drifts, the roller casing moves, due to the dead weight of the belt, so that a forward motion occurs which brings the belt back to its normal position. The roller casing returns to its normal position as soon as the corrective procedure is completed. The mechanics of the movement are rendered possible due to a complex ball joint in the centre of the roller as well as the position of the axle in relation to the conveyor belt being less than 90°.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The carrying frame prevents belt misalignment and guarantees protection of the belt edges. As the carrying frames only function efficiently when the drum casing is clean, they are equipped and delivered with dirt repellent 60° shore soft rubber. Our carrying frames can be used with both normal and reversing conveyor belts. Mode of operation When the conveyor belt is running straight, the axle through the roller casing forms an angle of 90° to the direction of movement of the belt. When the belt drifts, the roller casing moves, due to the dead weight of the belt, so that a forward motion occurs which brings the belt back to its normal position. The roller casing returns to its normal position as soon as the corrective procedure is completed. The mechanics of the movement are rendered possible due to a complex ball joint in the centre of the roller as well as the position of the axle in relation to the conveyor belt being less than 90°.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

close tolerances and longitudinally welded carrying roller tubes made of S235JR steel in accordance with DIN 2458; deep drawn steel bearing retainers with calibrated bearing seats pressed in from the side and circularly welded, material thickness min. s = 2.00 mm; RAL 3000 red powder coated sheath, coating thickness min. 60 U; 20 mm Ø round steel in accordance with ISO h9; single row radial steel ball bearings in accordance with DIN625 type 6204 with suitable grease filling and cover plates on both sides made of sheet steel C3 bearing clearance. The calculated service life of the ball bearings, assuming belt speed 2m/sec. delivery capacity 200 t/he bulk weight 0.75 t/m³ temperature range 0° C 50° C is 30,000 hours. Steel circlip in accordance with DIN 471 Sealing using double labyrinth seal, incl. suitable grease filling, galvanized, sheet steel sealing cap and plastic rain cap

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Carrying rollers made of steel and HDPE Carrying rollers suitable in both heavy and light application conditions bulk goods and unit load rollers also available for delivery with cogs and conical rollers delivery of small quantities possible

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

For the special requirements of your belt conveyor system, we manufacture for you drive pulleys, carrying idlers, throbbing drums, lift pulleys with or without internally located cone. With diameters up to max. 1,000 mm and lengths up to max. 4,500 mm, these are suitable for all types of belt conveyor system. All pulleys are turned cylindrically or spherically. The axle connections can be delivered in alternative designs with internal bearings, welded, with wedged connections or with clamping set shaft connections. Special designs such as stainless steel and/or friction linings (ceramic, rubber) and accessories (pedestal bearings) can be delivered upon request.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

For the special requirements of your belt conveyor system, we manufacture for you idler pulleys, carrying idlers, throbbing drums, lift pulleys with or without internally located cone. With diameters up to max. 1,000 mm and lengths up to max. 4,500 mm, these are suitable for all types of belt conveyor system. All pulleys are turned cylindrically or spherically. The axle connections can be delivered in alternative designs with internal bearings, welded, with wedged connections or with clamping set shaft connections. Special designs such as stainless steel and/or friction linings (ceramic, rubber) and accessories (pedestal bearings) can be delivered upon request.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

We manufacture and deliver the complete range of simple carrier roller holders, e.g. for the lower belt roll and 2 or 3 part upper belt stations in all trough angles. We are happy to manufacture and deliver simple to complex upper belt steering stations. We offer you Let us know when you inquire whether we should offer the conveyor roller stations in a primed, painted, galvanized or special version.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

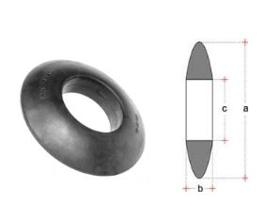

Support rings for type A carrying rollers Type A support rings prevent sap build up and the build up of dirt on the carrying rollers and ensure a straight run in the bottom strand. Support rings (rubber rings) from FTK Förderband Technik Kilian GmbH are attached permanently to the roller and are characterized by their abrasion resistance. In addition to the proven standard, we also manufacture special quality rings such as white food quality rings, oil and grease resistant rings, and rings for extreme temperature ranges ( 40° C to 180° C). Support rings for type B carrying rollers Rollers fitted with type B support rings are used as bottom belt rollers. They are generally placed on the ends of the carrying rollers. Support rings (rubber rings) from FTK Förderband Technik Kilian GmbH are attached permanently to the roller and are characterized by their abrasion resistance.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Due to its abrasion resistance and durability, polyurethane is well suited for use in the conveyor industry. Support rings for support rollers made of polyurethane are characterized by a very high wear resistance. In addition, the material is largely resistant to mineral and vegetable oils.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Buffer rings absorb the falling energy of the conveyed goods and thus protect the belt from damage. The buffer rings (rubber rings) from FTK Förderband Technik Kilian GmbH are permanently attached to the conveyor roller and are characterized by their wear resistant quality. In addition to the tried and tested standard, we also manufacture rings in special quality, e.g. B. white food quality, oil and fat resistant or for the extreme temperature range ( 40 ° C to 180 ° C).

Request for a quoteManufacturer/ Producer

Aegidistrasse 144-146a

46240 Bottrop - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

PARSMEGA MAKINA

Turkey

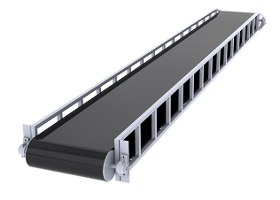

These are conveyors used for general transportation purposes, in the horizontal or inclined transmission of a wide variety of products to different distances. Material transportation in belt conveyors is provided by the belt stretched between the tension drum and the drive drum, which is moved by a motor-reducer system. Belt selection is made according to the type of product to be transported and types such as PVC, polyurethane, rubber and mesh belts can be selected. It is suitable for transporting boxed, bulk and packaged products. It is the conveyor type with the widest usage area, and its usage capacity is also highly variable. Conveyor leg group and chassis are made of Aluminum or electrostatic powder coated steel construction.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free