FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Manufacturer/ Producer

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

We constantly have a large supply of HM replacement segments and HM bars in stock and also manufacture spare parts which fit scrapers made by other producers. Production of special segments based on drawing possible construction possible in hard metal, HM ceramic and ceramic Spare parts for the following manufacturers also in stock Indutechnik, Schulmeistrat Industrie Technik, Masch, Belle Banne, Manuflex, Duroflex etc.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

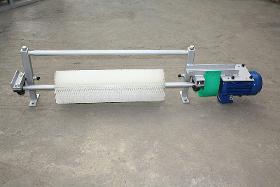

requires little space uncomplicated change of replacement brushes Edging nylon, wire, nylon/wire mixture, rubber, other edgings possible upon request. Areas of use belts with profile, cleat belts, old and damaged belts, belts for the transporting of glass etc

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Conveyor belt cleaning brushes with drive coupling and exterior motor infinitely variable positioning of the cleaning brush by means of telescopic spindles other edgings possible upon request. Edging nylon, wire, nylon/wire mixture or rubber

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

FTK Förderband Technik Kilian GmbH Brush strip wipers are made of highly wear resistant PP and are ideal for demanding applications in the field of bulk material, recycling and processing technology. The brush strips can be exchanged easily and simply when they are worn out. Inexpensive alternative for cleaning light conveyor belts in the lower belt without electric drive easy construction continuous brush strip easy adjustment by moving the spindle Areas of application sand, gravel, clay, brickworks, asphalt mixing plants, gypsum, cement, glass industry and much more

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Knocker rolls are used on the cleat belt in order to knock off adhering material. The Knocker roll is fitted in the inner belt near the drive pulley. Area of use cleat belts and badly damaged belts Knocker rolls are used when it is not possible to use conveyor cleaning brushes. They can also be used as combination together with a conveyor cleaning brush.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

high level of dust sealing at the location where material is fed onto the belt conveyor minimal wastage a buffer for the material falling onto the belt conveyor reduced cleaning costs increased conveyor belt service life increased operational safety simple assembly no welding necessary exchange of the adapter piece for existing conveyor rollers Measurements of the impact bars approx. 1240 x 100 x 75 (L x W x H) The impact bars can be fitted using the enclosed screws optimal alignment of the skirting rubber on the conveyor belt

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The impact elements consist of three components which are connected to each other by hot vulcanisation a special rubber mix with a shore hardness of 62° A which absorbs the occurring drop energy a coating of highly sliding UHMWPE and a thickness of 12 mm a vulcanised aluminium profile for easy installation of the bars

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The adapter pieces are made to order in accordance with your specifications.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The implementation of impact absorber stations provides effective protection against damage to the conveyor belt in the loading area. The belt is often pierced by sharp, large and bulky goods. Specially manufactured stations supporting impact bars absorb the impact speed. Repair and maintenance costs are thus reduced. In addition, the life expectancy of the conveyor belt and conveyor system is extended as well as the operating conditions significantly improved. Further advantages no jammed rollers causing belt misalignment absorb the drop energy, support the conveyor belt instead of the conveyor rollers in the transport area of the conveyor system and make a reliable running of the belt possible whilst ensuring the least possible friction. infinitely variable alignment to the angle of inclination by means of spindle displacement possible better material sealing due to adjustment of the material guide to within a millimetre

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The impact elements consist of three components that are connected to one another by hot vulcanization A special rubber compound with a hardness of 62 ° Shore A, which absorbs the falling energy A top layer made of high sliding UHMWPE and a thickness of 10 mm A vulcanized aluminum profile for easy installation of the beams Special bolts with M16x40 also available in M12

Request for a quoteManufacturer/ Producer

Aegidistrasse 144-146a

46240 Bottrop - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

PARSMEGA MAKINA

Turkey

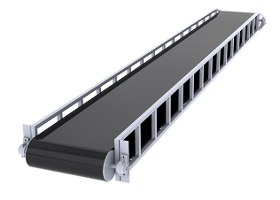

These are conveyors used for general transportation purposes, in the horizontal or inclined transmission of a wide variety of products to different distances. Material transportation in belt conveyors is provided by the belt stretched between the tension drum and the drive drum, which is moved by a motor-reducer system. Belt selection is made according to the type of product to be transported and types such as PVC, polyurethane, rubber and mesh belts can be selected. It is suitable for transporting boxed, bulk and packaged products. It is the conveyor type with the widest usage area, and its usage capacity is also highly variable. Conveyor leg group and chassis are made of Aluminum or electrostatic powder coated steel construction.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free