- europages

- >

- Rubber and plastic welding

- >

- DOREY

- >

- products

DOREY - Welding and Cutting Solutions for Flexible and Semi-Rigid Materials

France

Distributor

DOREY

France

F.E.B.A. Laminating System is suitable for laminating, slitting and rewinding heat activated or cold bond adhesive products to fabrics, foam/rubber, soft foam, cork, felt and similar materials. Standard and special machines available to suit the customers specific converting application. UNWIND UNIT The unwind unit is composed of one station for the axial unwinding of the master logs. Manual web guide left and right. One 3" removable pneumatic shaft and brake. DRAWING UNITS The first drawing unit is composed of two large diameter siliconized rubber covered rolls; suitable for the unwinding of high and low thickness foam rolls. The second drawing unit is composed of two large diameter siliconized rubber covered rolls and will be equipped with a separate brake and clutch to be used when laminating very thin elastic materials or slitting narrow widths. UPPER UNWIND The upper unwind is to keep the single sided tape to be transferred. Manual web guide left & right.

Request for a quote

DOREY

France

The F.E.B.A. automatic logging system was designed to unwind/rewind adhesive backed materials, paper, styrene, foils, woven and non woven, rubber, foam and other like materials. This logger is designed to accommodate master logs up to 1000MM in outside diameter with widths up to 1700MM (Standard Size Special Applications Available). MACHINE'S MAIN FEATURES Maximum material width is 1700MM. (Special Sizes Available) Maximum OD of the master jumbo log is 1000MM. (Special Sizes Available) Maximum OD of the rewound logs is 420MM. (Special Sizes Available) Working speeds from 0 120 meters per minute. (Other upon request) Rotary turret with two pneumatic shafts. Core inside diameters available in 1.5" or 3". Pneumatic jumbo roll shaft for 1.5" or 3" cores. Contrast jumbo roll and winding shafts The unwinding tension is adjustable with a pneumatic brake and a servodiameter valve. Path rollers coated in ceramic. (Plasma Coating)

Request for a quote

DOREY

France

Auto cutting of plastic ISO cards from sheets of stacked and printed material. Available for any commercial sheet format. FEATURES A combination of high volume production, accurate die cutting, and high quality card edges Inboard & outboard ball screw servo driven gripper unit with position accuracy of +/ 0.1mm The shear type male & female die ensures excellent clean cut edges The optical sensors with registration mark tracking system ensure a cut to print accuracy of +/ 0.1mm A card stacking unit with 2 interchangeable magazines, each holding up to 450 cards with a thickness of 0.8mm Scrap web is automatically discharged The touch screen monitor makes the machine easy to operate Complete CE safety guards An air flotation system protects the cards from scratching during the feeding process An auto sheet feeder with trolley holds approximately 1 000 sheets, with a sheet thickness of 0.8mm Special accessories are available for thze accurate punching of contact less plastic cards

Request for a quote

DOREY

France

Plastic card cutting, collecting, stacking and skeleton web removal system for card manufacturing industries. Available for any sheet size or printed card layout. Available for PVC, PC, ABC, PET a,d paper materials. Cutting credit card assembly, stacking and skeleton storage system for manufacturing ISO cards, available for any size sheet or PCB layout. PRODUCT DESCRIPTION High volume production rate Hihj speed and accuracy Low noise, low vibrations 100% servo motor driven Shear type male & female die sets for clean and quality cards edge Inboard & outboard ball screw servo driven gripper unit with +/ 0.1mm accuracy and precision Laser sensor registration mark tracking system with +/ 0.1mm accuracy Card collecting & stacking units with 2 interchangeable magazines for continuous operation Automatic skeleton web removal system User friendly touch screen monitor and operator interface systems CE approved safety standards

Request for a quote

DOREY

France

The preparation of tapes before lamination is often an important step in terms productivity. The new GCM works directly from overlays coils thickness from 0.04 to 0.4 mm with or without magnetic tape. Depending on the machine configuration, the hourly rate reaches 1200 format welded, cut to length and stacked. BENEFITS Fully automatic suction cup brings a destacker hearts in the process, capacity of 1000 sheets 0.7 mm thick. Cleaning sheets before being fed into the machine, each sheet passes PVC or PET in a special cleaning roller. You do not have to worry about the cleanliness of the cards before lamination. High technology, high precision alignment and positioning hearts compared with magnetic tapes. Depending on the heat size, the magnetic strip can be positioned much higher than the overlay on the bottom. In the assembly process, a special ultrasonic welding of two or three layers fixed with accuracy. High efficiency

Request for a quote

DOREY

France

Automatic Feeder approximately 1000 sheets per suckers Anti static bar and double sheet detection Gripping and transferring the sheets entering the air bag assembly is driven by a servomotor and ball screw to ensure accuracy in the positioning + 0.1 mm Mark detection for automatic alignment of the sheet by XY two high precision optical lasers + 0.1 mm Detecting printed marks on the Y axis by one laser precision optical alignment and automatic + 0.1 mm positioned at the inlet of the tool Tool punch die cavities horizontal or vertical SYSCO manufacturing Hydraulic quick and silent 5 Tons Stacking cards interchangeable with 6 stores Transferring sheets in output controlled by servomotor and ball screw Evacuation from falling rollers

Request for a quote

DOREY

France

The machine is fully automatic punching and stacking system for GSM cards (Global System for Mobile Communications). It is designed to punch the Subscriber Identity Module (SIM) and scribe a break out line according to the GSM 11.11 standard. BENEFITS Extraction of Individual cards from two removable loading magazines. The timing belt transporting system moves the cards from one workstation to another in a synchronized manner. SIM punching operation is driven by hydraulic system. Scribing of break out lines with pneumatic driven tool knife edge. Removal of waste material into an external container. Automatic stacking of the finished cards in two output removable magazines. Complete CE safety guards. The touch screen monitor makes the machine easy to operate and self diagnostic trouble shooting makes the machine user friendly.

Request for a quote

DOREY

France

You can work many formats with or without contact with high quality and suitable for lamination of contact and contactless plastic cards BENEFITS Heating and cooling presses are independent, so the costly heating up and cooling down of the hot platens during each production cycle is totally avoided. The main frame of the heating and cooling presses are constructed of rigid welded steel. The main hydraulic cylinders are hardened, ground and hard chromium plated. The platens are guided by frictionless material. Heating and cooling presses are operated by a separate hydraulic system. A low pressure pump is used to lift the platen at a quick speed, while a high pressure pump is used to keep the heating and cooling presses at a high pressure. The pressure settings at the different stages of heating and cooling are programmable. The closed loop transport system significantly reduces material cassette loading and transfer time, resulting in much reduced consumption of energy.

Request for a quote

DOREY

France

Heating and cooling presses are independent and operated by separate hydraulic system. A low pressure pump is used to lift the platen at a quick speed, while a high pressure pump is used to keep the heating and cooling presses at a high pressure. Heating and cooling presses are built from two solid welded frames, with all platens securely guided, allowing for a tremendously high rigidity of construction and thus , excellent parallelism of platens. This eliminates the undesirable effects of heat expansion. The pressure settings at the different stages of heating and cooling are programmable. High precision temperature control ( 1.5℃) is achieved through excellent circulation and monitoring of thermal heating oil. Manual transfer the material cassette from table stand to stand by stand. Uniform application of pressure thereby avoids discoloration. The heating temperature is evenly and accurately distributed across the total hot platen area.

Request for a quote

DOREY

France

Extraction of individual cards from two removable loading magazines The timing belt transporting system moves the cards from one workstation to another in a synchronizes manner Card thicjness measuring station ensuring only one card is fed CNC cavity high speed milling head for up to 60,000 RPM and dust extraction Hot melt tape spoller, puncher, laminating and peel off system to laminate with chip module tape Chip module punching station and pick & places system for chip module implanting in the cavities Bonding on chip into the card cavity Cooling press qtation Data input device Sorting of cards into good and reject magazines PC based control for easy operation Production capacity of up to 3,000 cards per hour Smooth, low impact operation reduces the noise level of hot melt adhesive Modular design Integrated hot melt lamination system Very stable ans consistent production process

Request for a quoteDistributor

250 rue des Artisans

26750 Chatillon St-Jean - France

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

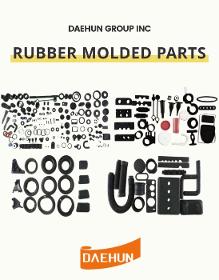

EC PLAZA

South Korea

Daehun Inc. has been supplying a wide range of rubber molded parts and sheets from China worldwide mainly in North America and Europe since 1990. - Daehun is manufacturing rubber molded parts for automotive & industrial and make constant efforts to sustain high-quality level for customer satisfaction firstly. - Daehun has the newest rubber test equipment and professional manpower in this field. Our development/quality control team meet the quality customer requires and provide benefit to customers by cost-reduction at the same time. - Daehun management utilizes our IATF Quality Systems as a focal point of our organization's approach to customer satisfaction. We subscribe to our quality program and continual improvement in every factory of our organization. - We pride ourselves in our ability to manufacture products to exacting quality standards and are dedicated to on-time performance.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Temperature range: 250 °C to 3200 °C 4-year warranty Durable IP65 (NEMA4) housing Manual Variable focus Sighting options: Laser through the lens and Visible through the lens Video Camera through the lens and Visible through the lens LED through the lens and Visible through the lens LAN/Ethernet interface with PoE for sensor communication (ASCII, Video, and Webserver) Profinet interface option Programmable relay output Fail-safe alarm Isolated analog input/output Rugged stainless-steel housing Dirty-window alarm Endurance software for remote configuration, remote monitoring and field calibration Single or two color models available APPLICATIONS Metals processing: molten metal/forging, hot rolling mills, rod/wire mills Heat treating & annealing Induction heating Lightbulb and halogen lamp production Glass melting Semiconductor furnaces Cement & lime kilns Refuse burning Carbon graphite production Foundry & welding Rubber & thick plastic

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Broad temperature range 50 to 3200°C 4-year warranty Durable IP65 (NEMA4) housing Visible through the lens sighting and manual variable focus plus optional laser sighting, video camera, or LED sighting LAN/Ethernet interface with PoE for sensor communication (ASCII, Video, and Webserver) Profinet interface option Programmable relay output Fail-safe alarm Isolated analog input/output Rugged stainless-steel housing Dirty-window alarm Endurance software for remote configuration, remote monitoring, and field calibration In addition to single-color models, the series also comprises two-color (ratio) pyrometers and models with a remote sensor head (Endurance Glass-Fiber). APPLICATIONS Metals: forging, hot rolling, rod/wire production Heat treating & annealing Induction heating Lightbulb and halogen lamp production Glass melting Semiconductor furnaces Cement & lime kilns Refuse burning Carbon graphite production Foundry & welding Rubber & thick plastic

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free