- europages

- >

- Rubber and plastic welding

- >

- DOREY

- >

- products

DOREY - Welding and Cutting Solutions for Flexible and Semi-Rigid Materials

France

Distributor

DOREY

France

This special Triad has been designed around the basic finishing needs of the digital graphics market. This package, based on the 1" (25mm) hem wedge and housing, can provide several welding functions including overlap, flat hem, hem cord and pole pocket welds. The Triad Digital Graphics Package is also available with a 1.5" (38mm) wedge for a larger finish size. For the bonding of thermoplastic textiles, the Triad Wedge Welding System is ideal for your in house fabrication needs to produce tents, tarps, awnings, flags, banners, liners, covers, curtains, bags, tubes, etc. The Triad can weld PVC, PE, PP, Urethane and many other weldable, flexible membranes. It can also weld supported and non supported material in thickness of 5 to 100 oz. and is designed to be portable, versatile and user friendly. HOW DOES IT WORK? The welding of various thermoplastics occurs by a combination of wedge temperature, material speed passing over the wedge, and pressure of the pinch rollers.

Request for a quote

DOREY

France

For the bonding of thermoplastic textiles, the Triad Wedge Welding System is ideal for your in house fabrication needs to produce tents, tarps, awnings, flags, banners, liners, covers, curtains, bags, tubes, etc. The Triad can weld PVC, PE, PP, Urethane and many other weldable, flexible membranes. It can also weld supported and non supported material in thickness of 5 to 100 oz. and is designed to be portable, versatile and user friendly. HOW DOES IT WORK The welding of various thermoplastics occurs by a combination of wedge temperature, material speed passing over the wedge, and pressure of the pinch rollers. The material is placed between the pinch rollers and the hot wedge is inserted. Contact is made between the top and bottom of the material and a melting of the coating occurs with a certain speed of the material crossing the hot wedge surface. The pinch rollers then apply pressure to the melted coating to create the lasting bond.

Request for a quote

DOREY

France

For the bonding of thermoplastic textiles, the Triad Wedge Welding System is ideal for your in house fabrication needs to produce tents, tarps, awnings, flags, banners, liners, covers, curtains, bags, tubes, etc. The Triad can weld PVC, PE, PP, Urethane and many other weldable, flexible membranes. It can also weld supported and non supported material in thickness of 5 to 100 oz. and is designed to be portable, versatile and user friendly. HOW DOES IT WORK? The welding of various thermoplastics occurs by a combination of wedge temperature, material speed passing over the wedge, and pressure of the pinch rollers. The material is placed between the pinch rollers and the hot wedge is inserted. Contact is made between the top and bottom of the material and a melting of the coating occurs with a certain speed of the material crossing the hot wedge surface. The pinch rollers then apply pressure to the melted coating to create the lasting bond.

Request for a quote

DOREY

France

Portable welding machine use fixed or mobile Welding width 50mm with 12mm groove Welding speed up to 20m/min with one single operator 1 aluminum body heating in 1000 or 2000 Watt 50 x 75 x 12 mm with special position for cleaning or changing Temperature control WATLOW high sensitivity SD series up to 490°C

Request for a quote

DOREY

France

For the bonding of thermoplastic textiles, the Triad Wedge Welding System is ideal for your in house fabrication needs to produce tents, tarps, awnings, flags, banners, liners, covers, curtains, bags, tubes, etc. The Triad can weld PVC, PE, PP, Urethane and many other weldable, flexible membranes. It can also weld supported and non supported material in thickness of 5 to 100 oz. and is designed to be portable, versatile and user friendly. HOW DOES IT WORK? The welding of various thermoplastics occurs by a combination of wedge temperature, material speed passing over the wedge, and pressure of the pinch rollers. The material is placed between the pinch rollers and the hot wedge is inserted. Contact is made between the top and bottom of the material and a melting of the coating occurs with a certain speed of the material crossing the hot wedge surface. The pinch rollers then apply pressure to the melted coating to create the lasting bond.

Request for a quote

DOREY

France

DUAL, INTEGRATED GUIDES FOR SPLINE/ KEDER/ ZIPPER BUILT IN TUNNEL GUIDES FOR BATTEN POCKETS PRESSURE CONTROL FOR PERFECT WELDS The Sigma 500 impulse welders takes all of the features of the 300 FastPocket and adds a second, integrated guide. The 500 still includes automatic hemming from 20 to 145mm as well as automatic overlaps, reinforcements and integrated guide for zippers, splines, or keders for two separate sizes. With the most advanced set of welding features available you can customize an almost limitless amount of individual and group recipes to achieve the perfect weld results every time. Operation is easy and convenient on the largest touchscreen available on the market that features real time feedback as well as color coded LED’s to offer visual indicators to what the machine is doing. Available from 4m to 8.4m lengths with bar thicknesses from 6 24mm, the 500 impulse welders from Sigma Engineering offer even more built in features

Request for a quote

DOREY

France

COST EFFECTIVE AUTOMATIC FOLDING AND HEMMING ABILITY TO SAVE PROGRAMS The Simple 100 welders from Sigma offer an entry level machine with world class performance. Designed to bring some automation to smaller factories, the Simple 100 offers automatic pocketing, welding, reinforcement, as well as semi automatic joining of materials. This series also features a touchscreen HIM interface for operation, large memory for saving welding parameters, mechanical adjustment of pocket sizes, and guides for joining fabrics. This series is offered in 3.2 and 4m lengths with welding bars available in 6,10,19, and 24mm thickness.

Request for a quote

DOREY

France

The automatic welding machine P2 is the innovative successor of the successful P models and an efficient and manoeuvrable device for welding truck tarpaulins, tents, awning materials and advertising banners. It produces optionally 20, 30, 40 and 45 mm wide overlap welds and may also be converted for welding in welting ropes. In addition, by mounting hem welding accessories, the automatic machine can without any difficulty be used for the production of 20 mm, 30 mm, 40 mm and 45 mm hems. The heat output of up to 4000 W 230 V AC is infinitely variable from 20 to 700 °C for an individual adjustment to different materials. The P2 starts automatically after the weld head has been swivelled in. In addition, the infinitely variable speed adjustment of the modern generation of motors with their performance of up to 18 m/min., in conjunction with the holding down device for crease free welding, makes for an optimum welding result.

Request for a quote

DOREY

France

Width 100 mm Bedplate and load bearing structure with easy dismounting Support cross members Main shaft group Front and rear plate unit Feed roller unit with micrometric adjustment Main drive unit Brush and feed rollers unit driven by servomotor Grinding wheel dressing unit gr. 36 Pneumatic control panel Electrical control panel Electronic programmable logic unit using a dedicated software for total management of machine functions with dust suction device CZ Dust Collector C4 Metering device (Alarm with light to inform about maintenance periods)

Request for a quote

DOREY

France

ROLL LOADING SOLUTION GENERAL INFORMATION Load rolls directly from the ground using your hand or feet. Battery operated, forget about crank handles or foot pumps. Possible to lift up to 1.2 meters to load rolls from racks. Lifting weight maximum 150 Kilos. Designed for rolls up to 3.2 meters wide. You can move the lifter sideways to pass through doors (80 cm). Loading rolls to the printer becomes a one person job. Quick Lifter is the best way to avoid back injuries among employees.

Request for a quoteDistributor

250 rue des Artisans

26750 Chatillon St-Jean - France

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

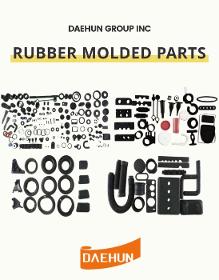

EC PLAZA

South Korea

Daehun Inc. has been supplying a wide range of rubber molded parts and sheets from China worldwide mainly in North America and Europe since 1990. - Daehun is manufacturing rubber molded parts for automotive & industrial and make constant efforts to sustain high-quality level for customer satisfaction firstly. - Daehun has the newest rubber test equipment and professional manpower in this field. Our development/quality control team meet the quality customer requires and provide benefit to customers by cost-reduction at the same time. - Daehun management utilizes our IATF Quality Systems as a focal point of our organization's approach to customer satisfaction. We subscribe to our quality program and continual improvement in every factory of our organization. - We pride ourselves in our ability to manufacture products to exacting quality standards and are dedicated to on-time performance.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Temperature range: 250 °C to 3200 °C 4-year warranty Durable IP65 (NEMA4) housing Manual Variable focus Sighting options: Laser through the lens and Visible through the lens Video Camera through the lens and Visible through the lens LED through the lens and Visible through the lens LAN/Ethernet interface with PoE for sensor communication (ASCII, Video, and Webserver) Profinet interface option Programmable relay output Fail-safe alarm Isolated analog input/output Rugged stainless-steel housing Dirty-window alarm Endurance software for remote configuration, remote monitoring and field calibration Single or two color models available APPLICATIONS Metals processing: molten metal/forging, hot rolling mills, rod/wire mills Heat treating & annealing Induction heating Lightbulb and halogen lamp production Glass melting Semiconductor furnaces Cement & lime kilns Refuse burning Carbon graphite production Foundry & welding Rubber & thick plastic

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Broad temperature range 50 to 3200°C 4-year warranty Durable IP65 (NEMA4) housing Visible through the lens sighting and manual variable focus plus optional laser sighting, video camera, or LED sighting LAN/Ethernet interface with PoE for sensor communication (ASCII, Video, and Webserver) Profinet interface option Programmable relay output Fail-safe alarm Isolated analog input/output Rugged stainless-steel housing Dirty-window alarm Endurance software for remote configuration, remote monitoring, and field calibration In addition to single-color models, the series also comprises two-color (ratio) pyrometers and models with a remote sensor head (Endurance Glass-Fiber). APPLICATIONS Metals: forging, hot rolling, rod/wire production Heat treating & annealing Induction heating Lightbulb and halogen lamp production Glass melting Semiconductor furnaces Cement & lime kilns Refuse burning Carbon graphite production Foundry & welding Rubber & thick plastic

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free