- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- zinc-nickel

Results for

Zinc-nickel - Import export

MBW GRUPPE

Germany

"The zinc-nickel process has developed in recent years into a process providing one of the most efficient coatings in surface refinement, and is primarily used where high corrosion resistance at a high temperature load is required. Zinc-nickel alloys with 12-16% nickel content are very temperature-resistant, the higher level of hardness compared to the normal zinc coatings is also a very important property, since the risk of damage is lower. The process is related to the conventional alkaline zinc method, but has excellent durability even without post-treatment. This process is suitable for both barrel and rack goods."

Request for a quote

METAL IN LTD

Bulgaria

Metal In has 9 eccentric presses with a force of 40 to 200 tons. We have loaders for roll operation and feeders. 3 hydraulic presses with a force of up to 160 tons. We produce press parts for the automotive, construction and furniture industries. Metal In is certified according to IATF 16949: 2016. We have a tool section for the production and maintenance of punches and bending tools. We also offer a subsequent operation of zinc and zinc-nickel.

Request for a quote

AICS BUSINESS SOLUTIONS CELIK SANAYI VE TIC. LTD. STI.

Turkey

galvanization electropolishing Zinc nickel coating Manganese phosphate coating chromate and hard chromate coating Cataphoresis coating Powder coating in various RAL colors and more

Request for a quote

SUN CHEMICAL - COLORS & EFFECTS NETHERLANDS B.V

Netherlands

Dithiophosphate IBS or Sodium Diisobutyl Dithiophosphate is a very good collector of nickel, zinc minerals (activated), and copper ores. It is also used within gold harvesting plants because of its ability to increase harvest of precious metals.

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

screws: nickel plates brass*zinc diecasting*for rods up to 16 mm Ø

Request for a quote

MBW GRUPPE

Germany

"The zinc-nickel process has developed in recent years into a process providing one of the most efficient coatings in surface refinement, and is primarily used where high corrosion resistance at a high temperature load is required. Zinc-nickel alloys with 12-16% nickel content are very temperature-resistant, the higher level of hardness compared to the normal zinc coatings is also a very important property, since the risk of damage is lower. The process is related to the conventional alkaline zinc method, but has excellent durability even without post-treatment. This process is suitable for both barrel and rack goods."

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

zinc diecasting*nickel plated*vinyl coated handles*width of mouth 59 mm

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

zinc diecasting, nickel plated*vinyl coated jaws*capacity 0 – 40 mm

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

zinc diecasting, nickel plated*vinyl coated jaws*capacity 0 – 40 mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CARL FRIEDRICH USBECK KG

Germany

zinc diecasting, nickel plated*for tubes up to 30 mm Ø*with wheel made from*hard metal

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

zinc diecasting*and brass,*nickel plated*vinyl coated jaws*length 300 mm

Request for a quote

KOVINSKI IZDELKI HRAST CNC TURNING

Slovenia

We have developed strong and reliable supply chain for applying additional part treatment beside machining. We can offer any kind of plating, heat treatment or grinding. Some of most common type of galvanic surface protection: Zinc plating in barrels and on racks zinc-nickel alloy in barrels phosphating in zinc phosphate nickel plating in barrels tinning in barrels copper plating in barrels chemical polishing and passivation of copper and copper alloys recrystallization annealing and tempering. Heat treatment: Hardening and tempering nitriding and nitrocarbunizing carburizing and carbonitriding annealing and other treatment.

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

steel, 8 mm Ø*zinc plated*three point support*nickel plated brass screw

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

Turned parts Long turned partes, small turned parts Turned, milled and grinded parts Thread inserts in brass, steel and stainless steel Possible materials: Alloy AlCuMgPb, AlZn5,5MgCu etc. Brass CuZn39Pb3, CuZn40Pb2 etc. Stainless steel 1.4301, 1.4305, 1.4571, 1.4401, 1.4101 etc. Steel Machining steel, St52, St37, C45, etc. Special steels Titan, Hastelloy, Copper, Bronze etc. Surface treatments may be done as follows: Galvanizing, nickel, brown, hot-dip galvanizing, phosphating, anodizing, chrome plating, painting, powder coating, plasma coating, sandblasting, Tuflok coatings. All common surfaces as VDA standard are possible (zinc-nickel, zinc flake). Heat treatments such as Plasma / gas nitriding, carbonitriding, hardening, carburizing, vacuum hardening, tempering etc.

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

screws: nickel plated steel*zinc diecasting*for rods up to 16 mm Ø

Request for a quote

MBW GRUPPE

Germany

"In this method, a process on the surface of zinc, zinc-iron or zinc-nickel produces a defined thin and durable passivation coating, which enhances corrosion resistance. The different passivation processes differ with regard to corrosion protection, appearance, coating thickness and colouring. Often the passivation processes are additionally enhanced by seals (topcoats). These topcoats not only provide even greater corrosion protection, but also provide a more uniform appearance. The topcoats are adjustable to define the friction properties. Passivation processes are provided exclusively chrome-6 free."

Request for a quote

DONGGUAN XINHONGYUAN METAL PRODUCTS LIMITED

China

This metal shell is made by progressive deep drawn stamping on 80T pnumatic press machine with +/-0.05mm tolerance for all dimensions, productivity is 60000pcs daily, which can be zinc or nickel plated with 24 hours for salt spray test.

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

zinc diecasting*and brass,*nickel plated*vinyl coated jaws*length 300 mm*safety base*Ø 82 mm

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Material Schulz Stanztechnik manufacturers these axial ball bearings using the materials suited to the specific application. For the housing, steel, brass or stainless steel are used; for rings, steel or stainless steel which is always hardened. The balls are made of chrome or stainless steel, which is also always hardened. All material combinations – depending on their conditions of use – are possible for the assembly of the individual parts. Various surface coats for the individual parts can be supplied as well as finished bearings: brass which is uncoated or nickel plated; steel and stainless steel which is uncoated, zinc plated or nickel plated. All bearings are available lubricated or unlubricated. Structure DLG100 axial ball bearings consist of sheet metal housing, two hardened rings as well as hardened precision balls. Due to their structure, we refer to them as an encapsulated, full ball design.

Request for a quote

NORELEM FRANCE

France

Housing, die-cast zinc. Housing cover, plastic, self-extinguishing. Hinge bolts, die-cast zinc/steel C45. Contacts, silver-nickel alloy 10. Note: The security hinge switches are used for monitoring the position of swing-hinged safety doors, protective hatches and hoods. The protective device is monitored directly in the hinge. By the universally pre-set versions, the switching angle is freely adjustable over the entire working range. A mounting aid ensures the quick alignment to doors and posts. The additional hinges have the same appearance and dimensions as the security hinge switches. The loading values given for the hinges are non-binding reference values without consideration of safety factors and exclude any liability. The values given are for information purposes only and do not constitute a legally binding assurance of properties.

Request for a quote

HONSEL-GROUP

Germany

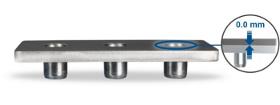

The HONSEL RIVET NUT "headless" can be used in existing and new applications. The blind rivet nut can be flush mounted in smooth bores without countersinking. The omission of the "countersink" process of the hole realizes enormous potential for savings. Due to the 0 mm protrusion, components can be mounted without interfering edges or slide over one another without obstruction. Advantages: — Flush mount in smooth bores — No countersink required — Protrusion 0 mm — No interfering edges — High-quality corrosion protection (zinc-nickel) with 720 h salt spray test resistance

Request for a quoteResults for

Zinc-nickel - Import exportNumber of results

104 ProductsCountries

Category

- Nickel plating (12)

- Zinc and zinc alloys (9)

- Turning - steels and metals (8)

- Sheet metals - stamping (7)

- Import-export - chemicals and pharmaceuticals (5)

- Clamp collars, plastic (4)

- Machine tools - metal machining (4)

- Machine tools, metal machining - parts and accessories (4)

- Screws (4)

- Steels and metals - machining (3)

- Magnets (2)

- Milling - steels and metals (2)

- Nuts and bolts (2)

- SMALL METAL PARTS (2)

- Stamping - steels and metals (2)

- Bearings, ball (1)

- Bending - steels and metals (1)

- Chemical catalysts (1)

- Connectors, electronic (1)

- Copper and iron hardware and fittings for furniture (1)