- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- workpiece carriers

Results for

Workpiece carriers - Import export

NERI MAKINA MÜHENDISLIK SANAYI VE TICARET LTD. ŞTI.

Turkey

Workpiece carriers guarantee safe workpiece handling - especially when it comes to reliably protecting sensitive workpieces from damage during transport and cleaning. We develop and produce workpiece carriers for high-precision and sensitive components. This means that the components are carefully embedded and positioned in customer-specific automation magazines in such a way that they are easily accessible for a gripper. In addition to being used with manual handling, the workpiece carriers are particularly suitable for customers with a high degree of automation. The tailor-made solutions are mainly used in production with automatic parts removal and in the material flow of the automotive supplier industry.

Request for a quote

NERI MAKINA MÜHENDISLIK SANAYI VE TICARET LTD. ŞTI.

Turkey

Neri-Mak designs and manufactures Stainless Steel Wire Baskets, and Custom Wire Baskets for customers in many different industries around the world. In addition to an extensive range of products, Neri-Mak develops and manufactures individual customer solutions with many years of experience and high technical competence. Our wide range of products makes it easy to adapt to a wide variety of logistics requirements. Our customers rely on Neri-Mak's know-how and technology to perfect every aspect of the design of your custom wire basket, from the shape of the cleaning basket to the materials used in it. The stainless steel wire baskets and customized cleaning Baskets are manufactured individually due to their geometrical shapes and to the individual requirements. Neri Mak has designed and produced over 2,500 different types of Stainless Steel Wire Baskets, Custom Wire Baskets, Stainless Steel Wire Mesh Baskets, Customised cleaning baskets.

Request for a quote

HOCHRAINER GMBH

Germany

Assembly line for micro gas generator (belt tensioner) Workpiece carrier transfer system (above/below level) with multiple automation stations

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Machining with 4 spindles OP 10 with 4 part clamping on workpiece carrier unit OP 20 with 4 workpieces on 2 rotary tables (5-axis machining

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

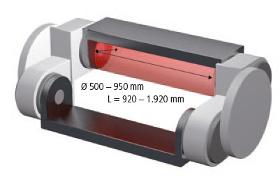

PENDULUM CHANGER – GOOD FROM EXPERIENCE. The W-axis principle, established by SAMAG since 1995, enables workpiece loading to be carried out parallel to production times. The workpiece carrier table is moved in the swivel drive from 0 – 180°. This means that the next loading and unloading of workpieces can take place during processing. Efficient and useful also for robot-assisted loading.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

The RS 1 robot system is a fully fledged combination cell for pallet and workpiece automation. The robot operates fully automatically, and can flexibly grip, clamp and store workpieces up to 15 kg and pallets up to 60 kg. The RS 1 guarantees process-secure production round the clock, whilst winning customers over with maximum flexibility and productivity! The rack storage concept makes for an unusually high degree of autonomous running; gripper and device changing is fully automatic and the fully functional setup station allows for pallets, workpiece carriers and workpieces to be set up in parallel with the main operation. This means that the RS 1 can be used as an automation solution for very diverse machining tasks.

Request for a quote

NERI MAKINA MÜHENDISLIK SANAYI VE TICARET LTD. ŞTI.

Turkey

Our range of products includes welded charging aids such as guide grids, charge carriers, tempering baskets, traverses, basket inserts, wire mesh baskets, charging baskets, heat-resistant workpiece carriers, as well as hardening boxes for the heat treatment of steel or other metals. good strength properties at high temperatures Continuous operation in air up to approx. 1150 ° C with temperature changes up to approx. 1000 ° C perfectly suitable for heat treatment We use according to customer requirements .EN 1.4845 / AISI 310S .EN 1.4841 / AISI 314 Both materials are heat-resistant steel. Due to the higher chromium and nickel content and have a good resistance to oxidation. The good strength properties are still present even at higher temperatures. Both also have excellent chemical resistance up to 1100°C.

Request for a quote

NERI MAKINA MÜHENDISLIK SANAYI VE TICARET LTD. ŞTI.

Turkey

The washing racks, so-called base frames, enable efficient cleaning with maximum flow. Dimensions can be individually defined by the customer. Several bulk goods baskets as well as several workpiece carriers can be cleaned at a single wash cycle at the same time. The washing racks each have 2 perforated strips on the front sides and can be closed with a locking or clamping lid depending on the load. Significant features and Benefits: • Easy adaptation to different logistic requirements. • Material made of stainless steel, electropolished. • Low weight with maximum stability and rigidity. • Good washing properties. • Wide range of options. • Suitable for both aqueous and solvent cleaning.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The "Metzner RPA 60-LT" is a powerful robot press automation with an outstanding storage system for the highest demands in the handling of pressed parts made of hard metal and metal powder. With a storage capacity of up to 60 sintering plates, the it offers outstanding possibilities for the production of sintered parts of all types. All sintering plates are fed to the machine via four transport trolleys with 15 plates each. The intelligent handling system of the "RPA 60-LT" ensures uninterrupted loading of the pressed parts. While the first sintering plate is filled by a linear robot with multifunctional gripper, the handling system provides a second empty plate. As soon as the first plate is filled, the loading of the second one starts. Meanwhile, the handling system returns the loaded sintering plate to the transport carriage. The automation thus works according to the Kanban principle, which ensures that the press can be operated continuously even during the workpiece carrier change

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The skid conveyor is an extremely flexible workpiece carrier system, especially used for defined process sequences. It can be loaded with any size of workpieces, from the sealing ring to a truck cabin. Skid conveyors reliably assume not only the cyclic but also the continuous transport, or perfect workpiece feeding within a production line, and they guarantee defined process sequences. Workpieces can be stacked, separated and/or removed, as required. VEN TRANS system techniques enable tailor-made workpiece conveying and handling concepts. We create Our solutions take into account

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

The new FLEXON SafeTopChain was designed with a completely closed upper surface, minimising the risk of crushing in curves or deflections and offering maximum stability for products and workpiece carrier systems. The special surface also enables even the smallest parts to be transported risk-free. Highlights: • Requires the same guides as the normal plastic multiflex chains from the 1700 Series • By using turning disks with a minimum radius of 123.5mm, dynamic friction is replaced by rolling friction; this allows longer conveyors with more curves, as well as vertical/spiral conveyor systems to overcome gradients and providing buffering. • Improved chain geometry enables the use of wider sprockets, thus reducing wear through lower surface pressure when teeth engage.

Request for a quoteResults for

Workpiece carriers - Import exportNumber of results

12 ProductsCountries

Company type