- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- winding machinery

Results for

Winding machinery - Import export

ROTH COMPOSITE MACHINERY GMBH

Germany

•Product development and small-scale production •Small footprint •Enables direct transfer of process parameters to automated capabilities •Highest precision and winding quality

Request for a quote

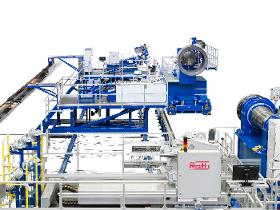

ROTH COMPOSITE MACHINERY GMBH

Germany

• High-performance series machine • Individual configuration according to customer requirements and process requirements • Can be integrated into production lines for Automation of production • Highest precision and winding quality

Request for a quote

ROTH COMPOSITE MACHINERY GMBH

Germany

•Serial production for large-scale parts •Carriage with maximum precision movable •Several carriages can be realized for additional materials •Highest precision and winding quality

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Our self-aligning ball bearings are characterised by their high load capacity and long service life. The KIS range includes both open and sealed self-aligning ball bearings, depending on the requirement. They are particularly suitable for applications with high demands on load performance and wear protection and are used, for example, in industrial machinery, wind turbines and conveyor technology. With low maintenance requirements, they offer long-lasting wear protection. Two rows of balls, two deep raceways in the inner ring and a hollow ball raceway in the outer ring combined for both rows characterise the design of self-aligning ball bearings. Due to the spherical raceway in the outer ring, self-aligning ball bearings are insensitive to misalignments of the shaft to the housing, compensating for static and dynamic angular errors within certain angular limits in a rotating shaft system. We are happy to develop the ideal KIS solution for your application requirements!

Request for a quote

KB SCHMIEDETECHNIK GMBH - A GERMAN DROP FORGE - CLOSED DIE FORGINGS - ALL STEEL GRADES

Germany

Gears are mechanical components and an essential part of many machines and are used in everything from piston engines to gearbox construction to agricultural machinery and wind turbines. Main gear types are: Spur and Pinion Gears: These gears have straight teeth and are the most common. They transmit rotational movements parallel to the axis and are found in gears, clocks and machines. Bevel Gears: These gears have tapered teeth and movement between non-parallel axes. They are used in differential gears of vehicles and in industrial machinery. Worm Gear: This combination of worm and worm wheel provides high gear ratio and is used in hoists, conveyors and other applications. Hydraulic The West German drop forge KB Schmiedetechnik GmbH produces forged gear blanks, piston parts and hydraulic components for a wide range of applications - from agricultural machinery and conveyor technology to engine construction, diesel generators to shipbuilding.

Request for a quote

CRB CUSCINETTI VOLVENTI

Italy

Deep groove ball bearings are the most commonly used type of bearing. Coming in many versions, varieties and dimensions, they are particularly versatile and can be used in a wide range of applications. They can withstand both radial and axial loads in both directions, even at high speed. They are especially suitable for all situations where high speed and low power loss are required. Features of deep groove ball bearings: ideal for high and very high speeds able to bear medium radial and axial loads in one or both directions easy to assemble, with minimal maintenance requirements Series: 600, 6000, 6200, 6300, 6400, 1600 Thin ring: 61800, 61900 APPLICATIONS: Earth Moving Machinery Electrical Motors and Gearboxes Iron and Steel Industry Agricultural Machinery Oil Industry Papermaking Machinery Wind Turbines Railways Semiconductors General mechanics Industrial Transmissions Pumps and Compressors Medical devices Food Processing Machinery

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Winding machinery - Import exportNumber of results

6 ProductsCountries

Company type