- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- thermal processing

Results for

Thermal processing - Import export

WIWOX GMBH SURFACE SYSTEMS

Germany

Service Cleaning: Our customers count on our contract cleaning team for their daily cleaning needs -. With modern cleaning processes e.g. thermal with pyrolysis, aqueous with ultrasonic or mechanical with lapping blasting we can clean and improve your high quality tools. Whether extrusion or injection molding tools, extruder screws, hot runners, nozzles, filters, molds, screens, adhesive or coating devices - everything will be cleaned by us for you! Detailed advice and documented cleaning of samples ensure consistent results over a long period of time. Test us - In addition to comprehensive advice, we offer you the opportunity to carry out your own cleaning trials of workpieces up to a length of 3 m and / or 4 t in weight. Cleaning trials: Every customer can convince himself of our offer by a free sample cleaning. Whether cleaning, surface treatment or decoating - with us you as a customer can see the result even before the first order!

Request for a quote

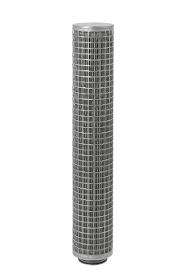

PORE FILTRATION

United Kingdom

Stainless Steel (St. St.) filters retain their strength as liquid temperatures increase which makes them suitable for elevated temperature liquid filtration, where polymetric (polypropylene, nylon, polyester or glass fibre) cartridges are not viable. Staineless Steel filter cartridges have: - A broad range of chemical compatibility - Mechanically strong which makes them ideal for high viscosity applications - Are cleanable either by ultrasonics or chemical cleaning - Reusable through many elevated temperature cycles Stainless Steel filters also play a key role in the filtration of steam due to their thermal strength protecting process equipment and pipework from damage by contaminants entrained in the steam.

Request for a quote

OSMO MEMBRANE SYSTEMS GMBH

Germany

Brine concentration In many applications of the chemical industries, a concentration by evaporation of mixtures and brines is necessary. Without membrane technologies, the whole volume flow of the process has to be evaporated. With an upstream reverse osmosis plant, the liquid flow can be pre-concentrated and condensed by a factor of 50-75%. The remaining volume flow is treated by a conventional evaporator. The energy consumption of the membrane systems is mostly significantly below of the consumption of the thermal processes, what makes a condensation by membrane plants very economical. Similar product: High pressure reverse osmosis

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Thermal processing - Import exportNumber of results

3 ProductsCountries

Company type