- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- shafts

Results for

Shafts - Import export

CIC - KLAUS CZERWONKA

Germany

Turned spindles, axles, shafts. Pistons for pneumatics, hydraulics, pumps. Ground, hardened, polished, chrome-plated.

Request for a quote

NORELEM FRANCE

France

Elastomer NBR. Brace ring and tension spring steel. Rotary shaft lip seals are readytoinstall seals for sealing rotating shafts. They are made from an elastomer outer sleeve and an internal bracing shim. The tension spring ensures increased pressure of the lip against the shaft and supports static sealing. Form A DIN 3760 (ISO 6194/1) version, smooth OD. Form AS DIN 3760 (ISO 6194/0) version, smooth OD with extra dust lip to protect from external dirt. The material NBR has a high wear resistance and is resistant to motor fuels, oil, hydraulic oil and lubricating grease. Operating limits Circumferential speed (m/s) ≤12 Pressure (MPa/bar) ≤0.05/0.5 (rotary shaft lip seals are generally meant for unpressurised operation).

Request for a quote

NORELEM FRANCE

France

Spline shafts based on DIN ISO 14 with straight parallel flanks. A spline shaft with spline hub is used to transmit high torques while enabling simultaneous axial movement. The spline shafts are colddrawn. Cold drawing does not interrupt the grain flow of the base material, ensuring spline shafts of very high strength. Tolerances Straightness 0.8 mm/m. Torsion max. 0.5 mm/m. On request Other lengths.

Request for a quote

NORELEM FRANCE

France

Standard ATprofile with metric pitch (trapezoidal toothing). For manufacturing your own toothed wheels

Request for a quote

FERRUM-MASCHINEN EIN BEREICH DER KMS AUTO UG (HAFTUNGSBESCHRÄNKT)

Germany

Cardan shaft medium complete with joints and grease nipples for wheel loader FERRUM DM625 x4

Request for a quote

FERRUM-MASCHINEN EIN BEREICH DER KMS AUTO UG (HAFTUNGSBESCHRÄNKT)

Germany

Short cardan shaft complete with joints and grease nipples for wheel loader FERRUM DM625 x4

Request for a quote

FERRUM-MASCHINEN EIN BEREICH DER KMS AUTO UG (HAFTUNGSBESCHRÄNKT)

Germany

Long cardan shaft complete with joints and grease nipples for wheel loader FERRUM DM625 x4

Request for a quote

FERRUM-MASCHINEN EIN BEREICH DER KMS AUTO UG (HAFTUNGSBESCHRÄNKT)

Germany

Rear cardan shaft complete with joints and grease nipples for wheel loader FERRUM DM416 x4

Request for a quote

FERRUM-MASCHINEN EIN BEREICH DER KMS AUTO UG (HAFTUNGSBESCHRÄNKT)

Germany

Front cardan shaft complete with joints and grease nipples for wheel loader FERRUM DM416 x4

Request for a quote

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

revolving shaft material: free-cutting steel finish: plated with white zinc edge milled, side tapped with thread Soochow Advance Industries Co., Ltd., (website: www.sai-parts.com) supplies custom OEM mechanical parts, industrial fasteners, screws, bolts, nuts, industrial fittings, electronic hardware by precision CNC machining, CNC turning, CNC milling, CNC engineering.

Request for a quote

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

turbine shaft manufactured by CNC turning material: cold drawn 18-8 (303) stainless steel, surface finish: passivation hex bar incircle diameter 5.556 +0.000/-0.060 mm internal thread: 8-32 UNC 2B, on both ends 2 grooves, width: 0.64 +0.10/-0.00 mm Soochow Advance Industries Co., Ltd., (website: www.sai-parts.com) supplies custom OEM mechanical parts, industrial fasteners, screws, bolts, nuts, industrial fittings, electronic hardware by precision CNC machining, CNC turning, CNC milling, CNC engineering.

Request for a quote

IGUS® GMBH

Germany

DryLin® R shafts and supported shafts - Technical data DryLin® R - AWMP Precision aluminum shaft, mm DryLin® R - AWMP DryLin® R - AWMU Supported aluminum shaft, mm DryLin® R - AWMU DryLin® R - SWM/EWM An steel or stainless steel precision shaft, mm DryLin® R - SWM/EWM DryLin® R - SWUM/EWUM Supported steel shaft orstainless steel shaft, mm DryLin® R - SWUM/EWUM DryLin® R - SWUMN/EWUMN Low supported steel shaft orstainless steel shaft, mm DryLin® R - SWUMN/EWUMN DryLin® R - EWUM Partially supported stainless steel shaft, mm DryLin® R - EWUM-Ø DryLin® R - CWM Carbon-fiber shaft, mm DryLin® R - CWM DryLin® R - AWMP Precision aluminum shaft, mm DryLin® R - AWMP DryLin® R - AWMU Supported aluminum shaft, mm DryLin® R - AWMU DryLin® R - SWM/EWM An steel or stainless steel precision shaft, mm DryLin® R - SWM/EWM DryLin® R - SWUM/EWUM Supported steel shaft orstainless steel shaft, mm DryLin® R - SWUM/EWUM DryLin® R - SWUMN/EWUMN Low supported steel shaft orstainless steel shaft, mm DryLin® R - SWUMN/EWUMN DryLin® R - EWUM Partially supported stainless steel shaft, mm DryLin® R - EWUM-Ø DryLin® R - CWM Carbon-fiber shaft, mm DryLin® R - CWM Aluminum Low weight Lower wear of the plain bearing Corrosion resistant Ideal in combination with liners made of iglidur® J/J 200 Delivered off the shelf Steel Low-priced standard High load capacity Application in dry area Hard chrome-plated also available Lower coefficient of friction against plastic bearing Stainless steel High corrosion-resistance High resistance to chemicals Ideal solution for the wet area V4A for extreme chemical intensive applications Female thread, axial male thread Pins Groove cut-in Spanner flat Female thread, radial Special machining All shafts can be individually machined. Please send us your drawing. We'll submit an offer to you in a short time. Shaft request

Request for a quote

IGUS® GMBH

Germany

iglidur® J260: ideal for plastic shafts Time and again the iglidur® J260 material proves its worth where the maximum service life and best friction coefficients are required under special application conditions - particularly in connection with plastic shafts! iglidur® J260 is available as cylindrical bearings and plain bearings with flange. Lubricants and maintenance-free Very good c.o.f. for low or medium loads Higher temperature resistance than iglidur® J Longer life time - even on polymer shafts

Request for a quote

NORELEM FRANCE

France

Steel 1.1213. Stainless steel 1.4034. Stainless steel 1.4112. Version Steel, ground. Steel, ground and hardchromed, chrome coating 5 10 µm. Stainless steel, ground. The precision steel shafts are generally inductively surface hardened. Note The surface value obtained during the inductive hardening process guarantees high surface wear resistance. Suitable for shaft supports 21565. On request Lengths up to a max. 4000 mm. Accessory Shaft supports 21565. Drawing reference 1) chamfered

Request for a quote

NORELEM FRANCE

France

Shaft support with bore for easy and secure clamping and fastening the guide shafts. Precision guide shafts 21595. Fastening screws 07160 or 07161.

Request for a quote

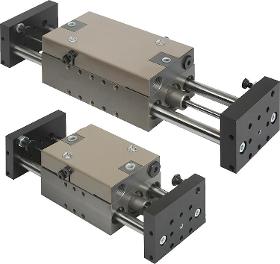

NORELEM FRANCE

France

Body and flange plate EN AW5754. Guide shafts steel Version Body, hardcoated Flange plates, anodised. Guide shaft, hardened. Note Maintenancefree pneumatic linear modules with two precision steel shafts and ball guide bushing with wipers. Double acting cylinder drive. All fastening threads have threaded inserts. The as accessory available shock absorbers and proximity switches can be integrated (no protruding edges). Positive fit construction for hundred per cent reproducibility. Combinations in all sizes and stroke variants are feasible without adapter plates. Repeat accuracies of ±0.01 mm are possible. Specified loads apply by centred carriages. On request Available with locking cartridge as stroke deviation safeguard. Accessory See table for shock absorber, proximitiy switch and plug connector.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

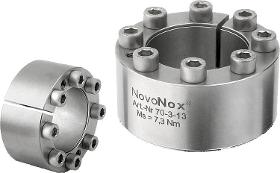

NORELEM FRANCE

France

Particularly compact selfcentring keyless locking coupling without axial offset. for shaft diameters from 8 to 85 mm for medium torques suitable for hubs with low wall thickness no axial offset selfcentring Assembly Lightly oil keyless locking coupling on the tapered faces and contact points of the shaft and hub. Do not use MoS2 or grease. Insert keyless locking coupling in the hub seat and slide onto shaft. Tighten screws crosswise in several increments to the defined tightening torque. Dismantling Remove all screws and screw into the extraction threads of the front flange. Tighten screws crosswise in several steps until the keyless locking coupling loosens. Tolerances Shaft Recommended tolerance h8. Surface quality Rz ≤ 16 µm. Hub Recommended tolerance H8. Surface quality Rz ≤ 16 µm.

Request for a quote

NORELEM FRANCE

France

Steel C45. Stainless steel 1.4305. Gunmetal Rg 7. Spline hubs based on DIN ISO 14 with straight parallel flanks. A spline shaft with spline hub is used to transmit high torques while enabling simultaneous axial movement.

Request for a quote

NORELEM FRANCE

France

Keyless locking coupling with low mass and moment of inertia. Easy to connect and release – no jamming on the shaft. Perfect for zero backlash connections. Excellent concentricity and running. Suitable for keyed and keyless shafts. for shaft diameters from 5 to 35 mm for high torques minimum axial offset when mounting selfcentring Assembly Shaft and hub must be free of oil, grease and dirt. Do not lubricate keyless locking coupling. Insert keyless locking coupling in the hub seat and slide onto shaft. Tighten nut by hand and use a torque wrench to tighten to the defined tightening torque. Tolerances Shaft diameter and hub hole Form A ±0.04 mm. Form B ±0.08 mm. Surface quality Rz ≤ 16 µm.

Request for a quote

NORELEM FRANCE

France

Coupling stainless steel 1.4057. Screws stainless steel 1.4301. For applications that require a small construction volume and low surface pressure. The keyless locking coupling can be fully recessed in a hub connection. for shaft diameters 6 20 mm suitable for hubs with low wall thickness minimum axial offset possible selfcentring Assembly Lightly oil keyless locking coupling on the tapered faces and contact points of the shaft and hub. Do not use MoS2 or grease. Insert keyless locking coupling in the hub seat and slide onto shaft. Tighten screws crosswise in several increments to the defined tightening torque. Dismantling Remove all screws and screw into the extraction threads of the front flange. Tighten screws crosswise in several steps until the keyless locking coupling loosens. Tolerances Shaft Recommended tolerance h8. Surface quality Rz ≤ 16 µm. Hub Recommended tolerance H8. Surface quality Rz ≤ 16 µm.

Request for a quote

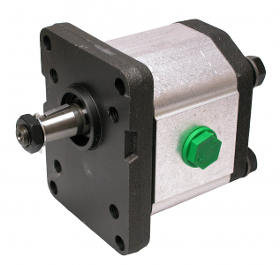

SCHMITTER HYDRAULIK GMBH

Germany

External gear pumps industry Material: Aluminum Series 2, clockwise English-Italian front-flange centering standard Ø 36,45 mm, conical shaft 1:8 with BSP threaded connection Category Hydraulic systems, valves and components / Hydraulic pumps / Gear pumps / 1-time / Size 2 / English-italian standard Ø 36,45 mm conical shaft 1:8 with thread connection, clockwise Product number supplier 452127272

Request for a quote

SCHMITTER HYDRAULIK GMBH

Germany

External gear pumps industry Material: Aluminum Series 2, clockwise English-Italian front-flange centering standard Ø 36,45 mm, conical shaft 1:8 with BSP threaded connection Category Hydraulic systems, valves and components / Hydraulic pumps / Gear pumps / 1-time / Size 2 / English-italian standard Ø 36,45 mm conical shaft 1:8 with thread connection, clockwise Product number supplier 452127272

Request for a quote

SCHMITTER HYDRAULIK GMBH

Germany

External gear pumps industry Material: Aluminum Series 1, clockwise English-Italian front-flange centering standard Ø 25.35 mm, conical shaft 1:8 with BSP threaded connection Category Hydraulic systems, valves and components / Hydraulic pumps / Gear pumps / 1-time / Series 1 / English-italian standard Ø 23,35 mm conical shaft 1:8 with BSP-thread connection, clockwise Product number supplier 452126071

Request for a quote

SCHMITTER HYDRAULIK GMBH

Germany

External gear pumps industry Material: Aluminum Series 1, clockwise English-Italian front-flange centering standard Ø 25.35 mm, conical shaft 1:8 with BSP threaded connection Category Hydraulic systems, valves and components / Hydraulic pumps / Gear pumps / 1-time / Series 1 / English-italian standard Ø 23,35 mm conical shaft 1:8 with BSP-thread connection, clockwise Product number supplier 452126071

Request for a quote

NORELEM FRANCE

France

The tension meter is used to perform a pretension test on commercially available belt systems quickly and easily by means of frequency measurement. Fully electronic and equipped with stateoftheart microprocessor technology, the meter enables precise adjustment of all V, toothed and flat belts that have to be tensioned in the range from 10 to 600 Hz. The measurement must never be performed while the drive is running The meter is not permitted or certified for use in potentially explosive areas.

Request for a quote

NORELEM FRANCE

France

Belt back and belt teeth CR. Tension cords Glascord. Tooth covering mesh polyamide. Note Endless toothed belts with an arched profile as per ISO 13050 with metric pitch. The rounded shape of the tooth contour provides a particularly high degree of safety against incorrect tooth interlocking, combined with a very rounded tooth mesh. Operating noise is significantly reduced by the rounded tooth mesh. The toothed belts are robust, economical and versatile. Belt speed vmax perm. 50 m/s Transmissible power up to 8.42 kW Permissible speed up to 14000 rpm Lownoise and lowmaintenance Very good chemical resistance, particularly against oils, greases and fuels Accurate positioning and angles

Request for a quote

NORELEM FRANCE

France

Endless toothed belt with trapezoidal profile to DIN 7721 T1 with metric pitch. Ideal for drives with high belt flexibility. Permits smallest pulley diameters. The toothed belts are intended for drives where precision is a requirement, safety is important and the effects of chemicals are a concern. maintenancefree highpower transmission minimal belt extension accurate positioning and angles very good chemical resistance, especially to oils, greases and fuels extremely high abrasion resistance transmits power up to 30 kW reliable speed up to 10,000 rpm

Request for a quote

NORELEM FRANCE

France

Standard HTD profile with metric pitch (rounded toothing). At least one toothed belt pulley must have a rim flange. Conical hole for taper clamping bushes. The taper clamping bushes must be ordered separately and are available for various shaft diameters. Pulleys with a taper hole are statically balanced as per ISO 1940 grade G16.

Request for a quoteResults for

Shafts - Import exportNumber of results

73 ProductsCompany type

Category

- Spare parts for diesel engines (6)

- Construction machinery (5)

- Bearings - ball, needle and roller (3)

- Coupling screws (3)

- Mechanical engineering - custom work (2)

- Filtering equipment and supplies (2)

- Joints, hydraulic (2)

- Steels, nickel (2)

- Transmission belts (2)

- Vehicles - mechanical components and parts (2)

- Sealing rings (1)

- Turning - steels and metals (1)

- Universal joints (1)

- SMALL METAL PARTS (1)

- Ceilings, suspended (1)

- Clamp collars, plastic (1)

- Electric and electronic components - machines for manufacturing (1)