- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- products for plants

Results for

Products for plants - Import export

TEMAS GROUP EXPORT PARTNERS

Turkey

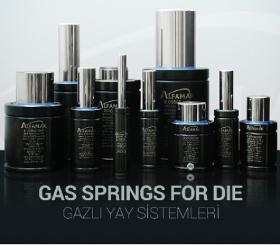

ALFAMAK is one of Turkey's leading gas spring manufacturers. Established in 2003, our company has been operating in the industry for 19 years and has gained a reputation for success. Gas spring is a new technology which comes instead of standard steel or polyurethane springs. A gas spring has a container of compressed Nitrogen gas with Piston Rod , Bush, Rod Rings, Valve etc. The Gas Springs are used in Cold Stamping industry to form, cut and fix the sheet metal inside the die. Many auxiliary materials are used for different purposes in the gas spring. Rod wiper, rod guide and rod seal are used on the inner surface of the bush. The purpose of the rod wiper is to prevent the oil and chips in the die from entering the gas spring. The rod guide is used to carry the load in case of axial force on the rod during use. The most important auxiliary material for sealing is rod/piston seal. It directly affects the performance of the product by keeping the gas in the gas spring.

Request for a quote

TEMAS GROUP EXPORT PARTNERS

Turkey

As Temas Group, we supply high quality cakes, biscuits, crackers, sauces and jams to African and European countries at affordable prices. We enrich your tables by combining flavour and economy. Our commitment to providing our customers with the highest quality products at the best prices is at the heart of our business. The unique flavours of our cakes, the crispy taste of our biscuits, the special aromas of our crackers and the naturalness of our jam varieties appeal to every palate. Our quality has become a reference for our customers looking for the same taste in every language. Working with a wide range of customers in Africa and Europe, we share our world of flavours with more people. Our supply chain guarantees that our products remain fresh and of high quality, while we pay special attention to customer satisfaction. We focus on the needs of our customers and aim to exceed their expectations. We continuously work to provide you with the best products and listen to your feedback.

Request for a quote

VEHGRO B.V

Germany

"History and Origin of Quinoa Quinoa (Chenopodium quinoa) is native to South America and has been grown as the main food crop since 6000 years ago. Quinoa was already used by the Incas as a field product. The plant is able to grow under cold, nutrient-poor and dry conditions. The growth period is about 5-6 months. Through crossbreeding, quinoa varieties have been created which can grow in European and North American conditions. In the first half of April the quinoa is sown in Europe and the harvest takes place from mid-September. Production Process Quinoa Flakes After harvest, the quinoa is first cleaned. Then the quinoa is washed to remove the saponin. Then it is dried and the best pieces will be selected by hand. These pieces are soaked to flatten the quinoa. After drying, the quinoa is sieved and then processed into quinoa flakes. Healthy properties Quinoa Flakes <Quinoa flakes are rich in vitamins B2, E, iron, copper and magnesium. Quino…"

Request for a quote

DANTECHS TECHNOLOGY CONSULTANCY INDUSTRY AND TRADE LTD.

Turkey

Rexroth Automation Components are used in various production plants.

Request for a quote

DANTECHS TECHNOLOGY CONSULTANCY INDUSTRY AND TRADE LTD.

Turkey

Fanuc automation components are used in various different production plants.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRIMO GROUP GMBH

Germany

Flexible and individual solutions FRIMO offers many different solutions in terms of combining tool carriers, mix and metering units, and the peripheral equipment necessary to complete production plants. Individual and turnkey production solutions are therefore highly available.

Request for a quote

DE SMET ENGINEERS & CONTRACTORS

Belgium

Thanks to its deep knowledge of all unitary operations related to edible oil, sugar and sugar fermentation processes, De Smet Engineers & Contractors is the ideal partner for assisting investors in developing and implementing biochemical production plants and bio-commodities production facilities. DSEC has already successfully built for international key players a betain and several inulin plants based on their proprietary knowhow. Moreover, DSEC’s experience in implementing cogeneration units built along with facilities for the production of fermentable grade sugar (derived from sugar beet, cane and grains) allows the company to fine-tune the overall process set-up in order to achieve ideal conditions with regard to material and energy flows. Notable examples of bio-based chemicals include non food starch, cellulose fibers and cellulose derivates, tall oils, fatty acids and fermentation products such as ethanol and citric acid for which. DSEC is fully qualified to provide the facility that will efficiently generate the required feedstock on an industrial scale. From a technical point of view, almost all industrial materials respectively their building blocks made from fossil resources can be substituted by their bio-based counterparts: • C2 building blocks: ethanol, acetic acid • C3 building blocks: lactic acid, 3-hydroxypropanoic acid, glycerol • C4 building blocks: fumaric acid, succinic acid, butyric acid, 1-butanol • C5 building blocks: itaconic acid, furfural • C6 building blocks: citric acid, glucaric acid, 5-HMF, adipic acid

Request for a quote

DE SMET ENGINEERS & CONTRACTORS

Belgium

Ethanol production plants construction requires a deep specialization that De Smet Engineers & Contractors processes over years of experience in projects implementation around the world and a very capable team of engineers that masters every detail of this business as well as all the technical capabilities required. In the same way it extended its activities from oil to biodiesel some years ago, De Smet Engineers & Contractors also identified bioethanol projects as a logical development of its general contracting activities where its sugar engineering experience was of utmost importance. The company has so far undertaken the construction of complete fuel ethanol plants using both cereals and sugarcane as feedstock. DSEC´s Contracting Services offers the client a wide variety of contractual setups from Conceptual Engineering, Front End Engineering Design (FEED) to Full Turnkey (EPC) or EPCM to adapt to every client needs.

Request for a quote

TUNCAPRM AUTOMOTIVE LTD TURKEY

Turkey

we are selling brake pad and brake lining production plant and know how.

Request for a quoteResults for

Products for plants - Import exportNumber of results

10 ProductsCountries

Company type