- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- on-site operation

Results for

On-site operation - Import export

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

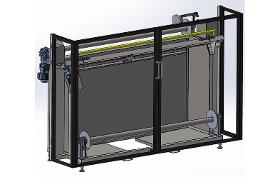

Trust in our experience and expertise to upgrade your existing industrial equipment in order to make it more technical and efficient and ensure its compliance. Our specialised teams will take care of : the technical upgrading and modernisation of your existing equipment in order to reduce your set-up times and/or increase productivity, as well as extending its operating life. the assurance that your facilities are compliant with the latest legal requirements in terms of safety/regulations. These operations can be carried out with the support of your maintenance teams or independently by our teams. We should specify that our teams have all the necessary clearances and qualifications, the insurance coverage for this type of work, and are highly experienced in on-site operations. Upgrade and retrofit operations are necessary to make significant productivity and operating gains, offering a particularly good return on your investment.

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

The textile industry is the fourth key industrial sector that has driven our growth because of the geographical location of TCM - THOMAS CONSTRUCTIONS MECANIQUES in the heart of the Vosges.special packaging, wrapping and labelling machines ergonomic workstations Related operations on customers’ sites : maintenance of equipment and infrastructure repairs technical upgrading of existing equipment Safety compliance of existing equipment Some practical examples : towel packing and labelling unit ergonomic handling workstation

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

As with the paper industry, because of the geographical location of TCM - THOMAS CONSTRUCTIONS MECANIQUES in the heart of the Vosges woodlands, the wood processing industry is the third key industrial sector that has driven our growth. Among many other customers, we work with the leading manufacturers of MDF panels and reels for the storage and transport of electrical cables Beyond special machinery, this collaborative work has helped us to develop specialist expertise in : the upgrading of existing production plants to reduce set-up and adjustment times and increase productivity conveyor systems wood cutting systems (sawing) wood sanding systems wood nailing and assembly systems Applications and projects : conveyor systems wood cutting systems (sawing) wood sanding systems wood nailing and assembly systems robotic units Related operations on customers’ sites : maintenance of equipment and infrastructure repairs

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

As a result of the geographical location of TCM - THOMAS CONSTRUCTIONS MECANIQUES in the heart of the Vosges, the paper industry is also one of the four historical sectors of activity that have driven our growth. We work closely with the main paper mills in the region which, despite the increasing global nature of their business, have still shown us unfailing loyalty. Beyond special machinery, this collaborative work has helped us to develop specialist expertise in : the upgrading of existing production plants to reduce set-up and adjustment times and increase productivity conveyor systems and roller elevators Applications and projects : conveyor systems roller elevators special packaging and wrapping machines the upgrading of existing paper mills to reduce set-up and adjustment times and increase productivity Related operations on customers’ sites : maintenance of equipment and infrastructure repairs

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

As a result of the geographical location of TCM - THOMAS CONSTRUCTIONS MECANIQUES in the heart of the Vosges, the agri-food industry is one of the four historical sectors of activity that have driven our growth. Among other organisations, we work with the main industrial cheese dairies in the region, which have shown us unfailing loyalty. Beyond special machinery, this collaborative work has helped us to develop specialist expertise in : the use and machining of stainless steel dosing systems for viscous foodstuffs food elevators Applications and projects : conveyor systems stacking systems food elevators process piping robotic units special packaging and wrapping machines dosing workstations cleaning systems control cabinets with PLC Related operations on customers’ sites : maintenance of equipment and infrastructure repairs technical upgrading of existing equipment Safety compliance of existing equipment

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BME BAUMASCHINEN ERSATZTEILE INH. DIPL.-ING.(FH) MATHIAS SCHMIDT

Germany

From us you get wearresistant track rollers made of highquality materials. They have been specially manufactured for use in industry. This means that they are particularly robust and can withstand even extreme operating conditions on site. The most important quality features are the high wear resistance and consequently the long service life. This is made possible in particular by the use of highquality materials such as boron steel. Deep heat treatments and the most precise machining processes are used in production. In addition, quality controls are carried out during and after production. This also ensures that the high requirements are met. Our goal is a high level of customer satisfaction, and this is achieved first and foremost through quality with the track rollers in our range.

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

High-Performance Plasma Cutting Machine: Built to handle harsh environmental conditions, suitable for on-site operations with a generator or in a workshop environment. Starting: Innovative and advanced arc starting without HF. Performance: Innovative and advanced electrode and nozzle design. Longer Lifespan: Innovative and advanced design increases the life of consumables. Faster: higher travel speeds and sheet thickness. Flexible: multiple torch configurations. Different materials: carbon steel, stainless steel, aluminum and many more. Concentrated plasma flow: less heat input, less distortion.

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

High-Performance Plasma Cutting Machine: Built to handle harsh environmental conditions, suitable for on-site operations with a generator or in a workshop environment. Starting: Innovative and advanced arc starting without HF. Performance: Innovative and advanced electrode and nozzle design. Longer Lifespan: Innovative and advanced design increases the life of consumables. Faster: higher travel speeds and sheet thickness. Flexible: multiple torch configurations and different materials: carbon steel, stainless steel, aluminum and many more. Concentrated plasma flow: less heat input, less distortion. What's included: 2 m input cable 7.5m manual cutting torch Earth and cable clamp Air Connection Kit Cutting Torch Consumables Kit

Request for a quote

COMPANY TOR

Russia

Welding inverters of the PRO series are light in weight and dimensions. The metal housing reliably protects the internal components, making it suitable for use on the construction site. Inverters are capable to operate with all brands of stick electrodes from 1.6 to 5 mm and 6 mm (VIKING 250PRO, VIKING 270PRO), including the УОНИ 13/55 brand. The minimum arc welding current is 30 A, the maximum one corresponds to the model. TP at maximum current for all models is 60%. Mains voltage range is 160 ... 260 V.

Request for a quote

COMPANY TOR

Russia

Welding inverters of the PRO series are light in weight and dimensions. The metal housing reliably protects the internal components, making it suitable for use on the construction site. Inverters are capable to operate with all brands of stick electrodes from 1.6 to 5 mm and 6 mm (VIKING 250PRO, VIKING 270PRO), including the УОНИ 13/55 brand. The minimum arc welding current is 30 A, the maximum one corresponds to the model. TP at maximum current for all models is 60%. Mains voltage range is 160 ... 260 V.

Request for a quote

COMPANY TOR

Russia

Welding inverters of the PRO series are light in weight and dimensions. The metal housing reliably protects the internal components, making it suitable for use on the construction site. Inverters are capable to operate with all brands of stick electrodes from 1.6 to 5 mm and 6 mm (VIKING 250PRO, VIKING 270PRO), including the УОНИ 13/55 brand. The minimum arc welding current is 30 A, the maximum one corresponds to the model. TP at maximum current for all models is 60%. Mains voltage range is 160 ... 260 V.

Request for a quote

UKF STAINLESS LTD (THE UKF GROUP)

United Kingdom

We provide our customers with the opportunity to get their materials processed before they even leave the warehouse – providing a leaner and more cost-effective manufacturing process. With large quantities of material stored on site, you’ll benefit from shorter lead times and better material availability compared to third party subcontractors. Thanks to recent investments, our manipulation service operates across two sites, equipped with several single and multi-stack benders and end-forming machines. Through these sites, we provide CNC and Press tube bending, end-forming and cruxiforming - providing the Group the capability to process and deliver orders faster than ever before. Our manipulation services are currently being employed within the automotive, domestic appliance and filtration industries.

Request for a quote

EFFIZIENTE.ST ENERGIE- UND UMWELTCONSULTING E.U.

Austria

The free tool requires manual input of meter readings, providing graphics for the specific consumption per day. It may also correlate two meters or transform odometer and fuel amounts into l/100 km or MPG. You may enter the meter reading(s) whenever you want, the server based software calculates the specific consumption. Your code encrypts your data, so the operator of the site has no access. By October 2016 SSL will be added to make it even safer.

Request for a quoteResults for

On-site operation - Import exportNumber of results

14 ProductsCompany type

Category

- Motor mechanics - hand tools, non power (6)

- Autogenous welding machines (3)

- Harvesting machinery and equipment (2)

- Welding, soldering and brazing - equipment and supplies (2)

- Bending - steels and metals (1)

- Construction machinery (1)

- Pipes and tubes, stainless steel (1)

- Shaping - steels and metals (1)

- Software - business management (1)

- Welding work - steels and metal (1)