- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wheel mills

Results for

Wheel mills - Import export

BULUT CNC MACHINING

Turkey

MATERIAL:DERLIN CNC TURNING AND CNC MILLING GEAR WHEEL

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Gear hobbing on CNC lathes without B-axis Years ago, EWS was the first tool manufacturer to offer gear hobbing heads in its standard range, and has continued to develop the holders for gearing technology ever since then. With this technology, it became possible for the first time to produce external gearing on machines without a Y/B-axis. In contrast to a standard milling wheel holder, the tool head of the EWS modular cutter can be swivelled about the axis of the shank. This offers users the advantage of substituting a B-axis with a comparatively small investment. In the meantime, module 3 has become commonplace on VDI40/BMT65/BMT75 machines. The tool heads have become more stable at the same time as being more user-friendly. The alignment system using a sinusoidal profile has come into widespread use and saves considerable alignment and setup times. Operating instructions, flyers and press reports can be found in our download portal Video: Gear hobbing on the

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-VU MILLED is the addition to the smooth model. This is accomplished by milling grooves into the coating of lamellae of foamed up Vulkollan®. The overall height of the coating is also adapted to the respective application and is therefore variable. The grooves can be cut into the coating in various widths, depths and angles. Due to the grooves inserted, contact discs with a milled design are significantly more aggressive than contact discs with a smooth design. The aggressiveness effect of the contact disk can be optimized for each application through an optimal groove width-groove depth-web width ratio so that high-performance processes are possible. With this contact disc, too, no signs of fatigue occur after long, intensive use if used properly.The contact discs of the FAPI-VU series are exclusively provided with a coating made of foamed Vulkollan®. We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-PA MILLED is the addition to the smooth model. At this type grooves will be milled in the rubber coating.The grooves can be milled into the coating in various widths, depths and angles. The total height of the covering can also be selected variably, with the standard height proven in practice being 20 mm. The higher the covering, the more elastic and therefore softer the contact disk surface appears. Due to the milled grooves, the contact disks are much more aggressive than smooth contact disks. The aggressive effect of the contact disk can be optimized for each application through an optimal ratio of groove and web width so that high-performance processes are possible. This contact disc also impresses with its longevity.The contact disks of the FAPI-PA series are exclusively provided with an NBR coating. We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

IBG HYDROTECH GMBH

Germany

The world's leading milling system enables the removal of deposits, roots, limestone, as well as protruding pipe sockets and preparation before rehabilitation measures. This is made possible by the use of the variable guide cage and the corresponding tooling with different milling wheels. Based on the WaMax milling motor, the user has a wide range of assembly and application options. Also suitable for egg profiles!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

The millGrind series is specially developed for the requirements of machining in the turbine industry as multiple technology solution in one set-up. The modular machine system in travelling table design allows an individual configuration of the machine according to the customers' needs. Automatic tool and diamond roll changing allows the machining to machine with — Al-oxide, CBN and diamond grinding wheels — Drills — Milling cutter — Laser cladding — Measuring of the unfinished workpiece — Measuring of the machine workpiece including rework in one set-up. This guarantees that all machined surfaces run to each other and errors are avoided by repeated re-chucking. In addition to the machining of new blades and vanes for rework a laser cladding device can be added. This allows the measuring, cladding and grinding or milling of the worn areas.

Request for a quote

CHAOYANG RUNXING HEAVY MACHINERY MANUFACTURING CO. LTD

Turkey

The Support roller is main used in rotary kiln / dryer / cooler and rotation device, usually there are two sets or three sets support roller in one rotary kiln, there will be a set support roller with thrust roller when three sets support roller be used. The support roller bear all weight of device, so it made by quality cast steel, and rolling through a axis in the center of support roller. zoeyguo369@gmail.com wechat:chaoyangrunxing

Request for a quote

FERNITE OF SHEFFIELD LIMITED

United Kingdom

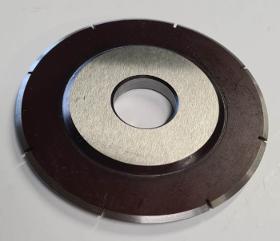

Circular knives, perforators, slitting knives & more - developed to your exact requirements. Fernite of Sheffield specialize in developing converting blades to optimize your production processes. Whether you have a particular cutting issue to solve, or want to improve the efficiency of your production process, we can help. With world-renowned expertise, advanced manufacturing capabilities and a helpful, supportive approach, we work with you to meet your needs. We offer a vast range of converting products, including: Core cutters Creaser blades Crush cutters Mill knives Perforation wheels Perforating knives Scoring blades Sheeter knives Slitter blades Trimmer knives Web cut-off knives

Request for a quoteResults for

Wheel mills - Import exportNumber of results

9 ProductsCountries

Company type