- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welding solutions

Results for

Welding solutions - Import export

SCHMIDT ZERSPANUNGSTECHNIK

Germany

SCHMIDT Zerspanungstechnik is the partner of choice for demanding welding solutions SCHMIDT Zerspanungstechnik's modern machinery offers a variety of welding options for the manufacture and working of components and large machine parts. As a dependable specialist in the processing of large parts, we can weld work pieces with a unit weight of up to five tons and flexibly adjust to accommodate different needs, including heat treatment and documented testing procedures: Our qualified and experienced staff are at home with various different welding techniques, such as MIG/MAG, TIG and arc welding. On request, we can carry out hardfacing of work pieces and large parts and employ special welding methods as part of the contract manufacturing service. Do you have any special wishes or requirements? We also weld custom solutions and highly complex parts with the utmost precision - on time and for a reasonable price. Our welding workshop is certified according to DIN EN ISO 3834.

Request for a quote

COPIER MACHINERY

Netherlands

The core of the Rotoweld technology is its unique vision-based penetration control system. It enables any operator to perform high-quality girth welds after just a few hours of training. Like the welder’s eyes and hands, the system continuously analyzes the image of the root weld pool picked up by a video camera integrated into the welding arm. Unique algorithms use this information to adjust welding parameters, such as travel speed, wire feed rate, arc voltage, or weaving width. This constantly adapts the process to varying conditions, such as changes in the gap, alignment, root face, or temperature. The computer’s fast reaction time means the machine can work at high deposition rates and travel speeds at which weld pool conditions are too critical to be sustained by hand.

Request for a quote

COPIER MACHINERY

Netherlands

The core of the Rotoweld technology is its unique vision-based penetration control system. It enables any operator to perform high-quality girth welds after just a few hours of training. Like the welder’s eyes and hands, the system continuously analyzes the image of the root weld pool picked up by a video camera integrated into the welding arm. Unique algorithms use this information to adjust welding parameters, such as travel speed, wire feed rate, arc voltage, or weaving width. This constantly adapts the process to varying conditions, such as changes in the gap, alignment, root face, or temperature. The computer’s fast reaction time means the machine can work at high deposition rates and travel speeds at which weld pool conditions are too critical to be sustained by hand.

Request for a quote

FOCQUET

Belgium

"The high voltage motors can be made of cast iron or welded steel (lighter solution). HIGH VOLTAGE MOTORS WITH CAGE: - Three-phase motors with cast iron cage - High voltage motors between 3 and 13.8kV - Power from 160kW to 10MW - IP55 or IP23 protection - Efficiency IE3/IE4 (tomorrow IE5) - Standard or custom sizes are available for sale - 2-4-6 poles stocked motors up to 1,2MW, IC411 cooling - Customized motors according to your specifications or to replace an existing motor will be delivered to you - Cooling mode IC411-IC416-IC511-IC611-IC616-ICW81 - Ball or sleeve bearings"

Request for a quote

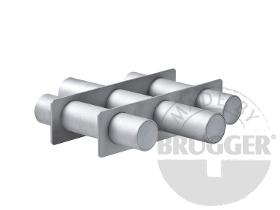

BRUGGER GMBH MAGNETSYSTEME

Germany

The above mentioned filter bars are our standard designs. Here the end pieces are not sealed tight and therefore only suitable for dry applications. Not available ex stock, manufactured on demand Alternative to the standard we also offer individual solutions: » Seal-welded model for use in liquids (e.g. water, coolant) » High-quality stainless steel enclosure for use in food production » Increasing the max. operating temperature up to 350 °C » Manufacture of individual, not standardised sizes

Request for a quote

BRUGGER GMBH MAGNETSYSTEME

Germany

The above mentioned filter bars are our standard designs. Here the end pieces are not sealed tight and therefore only suitable for dry applications. Not available ex stock, manufactured on demand Alternative to the standard we also offer individual solutions: » Seal-welded model for use in liquids (e.g. water, coolant) » High-quality stainless steel enclosure for use in food production » Increasing the max. operating temperature up to 350 °C » Manufacture of individual, not standardised sizes

Request for a quote

BRUGGER GMBH MAGNETSYSTEME

Germany

The above mentioned filter bars are our standard designs. Here the end pieces are not sealed tight and therefore only suitable for dry applications. Not available ex stock, manufactured on demand Alternative to the standard we also offer individual solutions: » Seal-welded model for use in liquids (e.g. water, coolant) » Other fastening options (e.g. external, internal threads and threads measured in inches) » High-quality stainless steel enclosure for use in food production » Increasing the max. operating temperature up to 350 °C » Manufacture of individual, not standardised lengths up to 2000 mm

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP® Tank Refurbishing Quantities change and existing tanks become too small – these are also problems that frequently arise. In such cases, the mobile machine technology from Lipp using the LIPP® DoubleSeam System or the LIPP® welding technique offers a solution that is as simple as it is costeffective, while being extraordinarily stable. Tanks can be installed on site in any size required and can be placed in an existing steel or reinforced concrete basin using a mobile crane. The existing tank volume is utilised, eliminating the need for expensive demolition work. There is also a range of materials to choose from for the tank itself so that it can be optimally matched to the intended application. VERINOX®, the combination material developed by LIPP® consisting of galvanised steel (for the outside of steel containers) and stainless steel (for the inside of containers), is characterised in particular by the excellent costbenefit ratio that it offers.

Request for a quote

BRUGGER GMBH MAGNETSYSTEME

Germany

The above mentioned filter bars are our standard designs. Here the end pieces are not sealed tight and therefore only suitable for dry applications. Not available ex stock, manufactured on demand Alternative to the standard we also offer individual solutions: » Seal-welded model for use in liquids (e.g. water, coolant) » High-quality stainless steel enclosure for use in food production » Increasing the max. operating temperature up to 350 °C » Manufacture of individual, not standardised sizes

Request for a quote

BRUGGER GMBH MAGNETSYSTEME

Germany

The above mentioned filter bars are our standard designs. Here the end pieces are not sealed tight and therefore only suitable for dry applications. Not available ex stock, manufactured on demand Alternative to the standard we also offer individual solutions: » Seal-welded model for use in liquids (e.g. water, coolant) » Other fastening options (e.g. external, internal threads and threads measured in inches) » High-quality stainless steel enclosure for use in food production » Increasing the max. operating temperature up to 350 °C » Manufacture of individual, not standardised lengths up to 2000 mm

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

SYSTEM FOR THE COST EFFECTIVE REFURBISHING OR VOLUME EXPANSION OF CONTAINERS OR TANKS Changing conditions, material wear, a change to the filling medium – these are just a few of the factors that lead to the replacement of containers used in industry or at municipal sewage treatment plants. Quantities change and existing containers become too small – these are also problems that frequently arise. In such cases, the mobile machine technology from Lipp using the LIPP Double Seam System or the LIPP welding technique offers a solution that is as simple as it is cost effective, while being extraordinarily stable. Containers can be installed on site in any size required and can be placed in an existing steel or reinforced concrete basin using a mobile crane. The existing container volume is utilised, eliminating the need for expensive demolition work. Utilisation of the existing container volume High stability, leak tightness and safety Continuous adaptation to existing container

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ-Spiral conveyor are used wherever bulk solids have to be conveyed in a vertical direction. These robust spiral conveyors are suitable for conveying a host of bulk solids from various production processes. These can be fine to coarse-grained, as well as fragmentary bulk solids. Our spiral conveyors are used in the chemical, pharmaceutical and food industries, and also in the raw material industry. The use of additional fixtures enables products to be treated by thermal (cooling/heating) or technical (drying) processes. The bulk solids can be transported both upwards or downwards. The spiral conveyor, which offers large heat exchange surfaces from a small footprint through its coils, is an especially cost-effective solution. A laser-welded version, which offers maximum density in return for minimum heat admission during manufacturing operations (no welding stresses to cause delays), is playing an increasingly important role for these special units. Advantages & benefits energ

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ-vibrating heat exchanger are used in a number of processes in which bulk solids have to be cooled, heated, dried etc. These special-purpose units are able to perform the heat exchange process during transportation. Usually, this occurs indirectly through the use of double bottoms to accommodate the heat exchange medium (oil, water, air, etc.). AViTEQ heat exchangers are employed in practically every industry (chemical, food, plastics, pharmaceutical, recycling and raw materials). The spiral conveyor, which offers large heat exchange surfaces from a small footprint through its coils, is an especially cost-effective solution. A laser-welded version, which offers maximum density in return for minimum heat admission during manufacturing operations (no welding stresses to cause delays), is playing an increasingly important role for these special units. Advantages & benefits gentle product treatment optimised and customised modification to suit existing processes low wear and pra

Request for a quote

MINEBEA INTEC GMBH

Germany

The MP 79/79T Bending Beam Weigh Cell is made from stainless steel and is available in a load range from 227 kg to 5099 kg. This weigh cell is specially designed for use in weighing platforms and simple hopper weighing applications. Protection class IP68, IP69K For economic vessel weighing solutions Hermetically welded IP68/IP69 Load cell capacity range from 227 kg to 5.099 kg Accuracy class: 0.02 % Corresponding mounting kits

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Ensure sample purity for microfluidic diagnostic systems POREX ® microfluidic media and filters provide sample filtration and absorption, particulate capture, debubbling, venting, fluid metering, and separation for real-time, PCR and molecular diagnostics systems. Our highly specialized, pure materials and media are critical to the function of lab-on-a-chip, molecular diagnostics, and POC analysis solutions by: Minimizing interference with critical samples and assays – Certified Pure POREX® materials certified by independent test labs ensure optimal performance, accuracy and reproducibility. Making manufacturing easier – Our components can be easily inserted into your device using common manufacturing techniques including press fitting, heat staking and ultrasonic welding. Providing customized material solutions – Our proprietary material technology expertise can help find the right material solution for any microfluidic component need. Applications Sample...

Request for a quote

WEBER ULTRASONICS AG

Germany

For agile welding tasks in close quarters, small lots or prototyping, the HSM Hand Welding Module is the perfect solution. This ergonomically shaped tool is splash-proof and convinces with durability. The HSM is always configured to your specific needs and comes with a Sonotrode tailored to your task.

Request for a quote

LACERS GMBH

Germany

ECO-Sealer-300 with cutting device The ECO-Sealer is an economically optimal solution for the welding/sealing of smaller runs, and they are also very well suited as a starting point for the manual sealing of your packaging. The ECO sealers are ideal for sealing PE (polyethylene) and PP (polypropylene) films. The impulse welders of the ECO series do not require any warm-up time, they are ready for use immediately after activation. They have an adjustable timer with indicator light. This will help you to create the optimal welding seam / sealing seam for your film. This model is also equipped with a cutting device. At a glance: Impulse welder with cutting device suitable for welding PE and PP foils Version with time switch different weld lengths possible Spare parts/accessories available suitable for welding max. 2 x 150µ Weld length: 300 mm Weld width: 2 mm<

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BRUGGER GMBH MAGNETSYSTEME

Germany

The above mentioned filter bars are our standard designs. Here the end pieces are not sealed tight and therefore only suitable for dry applications. Not available ex stock, manufactured on demand. Alternative to the standard we also offer individual solutions: » Seal-welded model for use in liquids (e.g. water, coolant) » High-quality stainless steel enclosure for use in food production » Increasing the max. operating temperature up to 350 °C » Manufacture of individual, not standardised sizes

Request for a quote

IMS - INTEGRATED MECHANIZATION SOLUTIONS BV

Netherlands

At IMS, we combine the power of precision laser welding with our expertise in precision engineering. We do this to provide innovative and reliable solutions to weld microwires for the production of medical devices and medical implants.

Request for a quote

BASAK LAZER

Turkey

We offer welded construction solutions using gas metal arc, argon, MIG, TIG and Laser welding technology according to the requirements of our customers. Welding is the process of joining two or more materials with the effect of heat and/or pressure, with or without the use of additional materials. In addition to the joining process, the welding process is used in coating and filling processes. Today, there are many different welding methods. It is a type of process that is used extensively in the industry. Welded manufacturing is defined as a special process in international standards. For this reason, there are international standards in order to guarantee and level the quality level in welded manufacturing.

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

Discover the BesterMIG 200-S Inverter, a technological innovation that will radically change your approach to welding. Synergy technology transforms welding by automatically adjusting parameters . With Synergy, the difficulties of determining the ideal current, wire feed speed and correct material thickness are a thing of the past. This adaptive technology assists your welding needs, ensuring remarkable results with minimal effort. By reducing the margin for error, Synergy offers high quality welds with reduced costs. Increase your efficiency and productivity with automatic adjustments that save time and facilitate the welding process. Portable and compact multi-process equipment: MIG/MAG, FCAW, MMA and TIG Lift. Equipped with SYNERGY based on automatic selection of welding parameters Perfect solution for hobbyists and DIY enthusiasts: makes welding faster and more effective

Request for a quote

AVK REWAG

Netherlands

Repair coupling for elbows (only for long radius elbows, R >= 1.5D), bends or weld provides a repair solution for all pipesthat needs to be repaired permanently or temporarily. Available in DN 13-500 Easy installation by use of a teorque wrench, limited space required for installation due to compact design Pressure range up to 53 bar (769 PSI) depending on size Main components of stainless steel 316 Green PTFE coated bolts Light weight

Request for a quote

AVK REWAG

Netherlands

Repair coupling for elbows (only for long radius elbows, R >= 1.5D), bends or weld provides a repair solution for all pipes that needs to be repaired permanently or temporarily. Available in DN 13-500 Easy installation by use of a teorque wrench, limited space required for installation due to compact design Pressure range up to 53 bar (769 PSI) depending on size Main components of stainless steel 316 Green PTFE coated bolts Light weight

Request for a quote

AVK REWAG

Netherlands

Repair coupling for elbows (only for long radius elbows, R >= 1.5D), bends or weld provides a repair solution for all pipes that needs to be repaired permanently or temporarily. Available in DN 13-500 Easy installation by use of a teorque wrench, limited space required for installation due to compact design Pressure range up to 53 bar (769 PSI) depending on size Main components of stainless steel 316 Green PTFE coated bolts Light weight

Request for a quote

AVK REWAG

Netherlands

Repair coupling for elbows (only for long radius elbows, R >= 1.5D), bends or weld provides a repair solution for all pipes that needs to be repaired permanently or temporarily. Available in DN 13-500 Easy installation by use of a teorque wrench, limited space required for installation due to compact design Pressure range up to 53 bar (769 PSI) depending on size Main components of stainless steel 316 Green PTFE coated bolts Light weight

Request for a quote

BASE GROUP SP Z O.O.

Poland

Base Group is the first manufacturing company in Poland to have successfully launched an electronic system for welding process management. Our system oversees welding of steel structures for power industry, offshore construction welding, structures for customers from the railway industry and welding of structures for the chemical industry. This is actually our next step into Industry 4.0. The electronic system for welding process management is a solution to be used from the first stage of planning the welding work, through coordination of welding the structures, up to the final stage of project reporting. Since we have implemented the electronic system for management of the welding process, the following have been completed with its support: – heat exchangers, – flanges for high voltage line insulators, – supporting structures for high voltage insulators, – frames for fans of engine cooling systems, – foundations for marine engines, – refrigerating container for locomotives, – tanks

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

In order to make use of the many benefits of ultrasonic welding, Herrmann Ultraschall realizes special solutions for many other packaging variants. Thanks to long-term experience in terms of key functions, such as guiding, movement travel, drive, and force build-up, it is possible to implement customer requirements, such as cycle time, and space specifications in a targeted and efficient way.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

This precisely guided system safely and quickly seals through product residues in the seal area. Narrow seals and reduced head space above the product contents save packaging materials. Operational costs are significantly reduced while the quality of products is ensured. Elements, such as film pusher units, temperature adjustment of weld tools, and special solutions for machines with lateral fold-open equipment, are optionally available.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

1. Provides circumferential welding (lathe welding) for tube, pipe, vessel…etc. in an easy operation but good welding quality solution. 2. This optimizes any process which reduces welding costs and improves the quality of the weld. 3. Suitable for TIG (GTAW), MIG (GMAW), Plasma (PAW) and Sub Arc welding (SAW) process. The style main frame design that allows 7 angular position adjustment from vertical to horizontal position (0° ~ 90°). Index welding is also available in this series.

Request for a quoteResults for

Welding solutions - Import exportNumber of results

39 ProductsCountries

Company type

Category

- Welding, electric - equipment and supplies (6)

- Laser - cutting and welding machines (2)

- Welding work - steels and metal (2)

- Automation - systems and equipment (1)

- Electric motors and parts (1)

- Harvesting machinery and equipment (1)

- Industrial sheet metal work (1)

- Milling - steels and metals (1)

- Packing and packaging - machinery and equipment (1)

- Storage tanks (1)

- Tanks, metal (1)

- Technical textiles for industrial applications (1)

- Weighing and dosing equipment (1)