- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- waterjet cutting

Results for

Waterjet cutting - Import export

ESTIMET SP Z O.O.

Poland

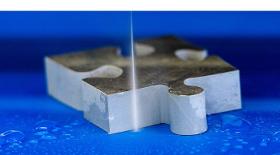

Our services include water sheet metal cutting. The parts we cut comply with the EN 1090 standard, and therefore with the CE mark. We use the waterjet cutting method for various types of parts whose dimensions do not exceed 2000 x 4000 m and whose thickness is up to 200 mm. We cut with a stream of water with an admixture of abrasive at a pressure of 60,000 PSI, without introducing heat into the material, so we can cut in addition to steel materials: - stone - marble - plastic - rubber - glass The WaterJet method, or waterjet sheet metal cutting, involves the use of a jet of water at very high pressure - often supplemented by the addition of an abrasive. The jet is directed at the surface to be processed, which makes it possible to cut a shape in it with the desired dimensions. Modern WaterJet technology is an attractive alternative to plasma or laser cutting.

Request for a quote

MECANIC SYSTEMS SA

Belgium

In order to provide optimum customer service, by offering blanking for a whole series of materials that cannot be cut by laser, Mecanic Systems has equipped itself with a "Water Jet" blanking machine with 4 heads. This machine can cut, without any transfer of heat, distortion or discoloration, with a tolerance of +/- 0.2mm, materials such as: -Steel up to 50mm -Stainless steel up to 50mm -Aluminium up to 50mm -PVC,Copper, bronze,Glass, stone, marble, Wood,… This by means of water and an abrasive using a pressure varying between 1000 and 3600 bars.

Request for a quote

BLASQEM, LDA.

Portugal

Range of products manufactured mainly in the USA. Decades of experience in the development and manufacture of components and waterjet cutting systems, allow us to present our customers with high performance solutions at reduced costs.

Request for a quote

PI-METÁL

Hungary

Unlike other technologies waterjet cutting is a cold-cutting process that can cut almost any material. It also provides a high-quality solution in cases where other methods even if applicable, but are less effective. By using this technology the surface will not be harmed, - no hardening, no humping, no melting and no gas formation. Cutting certain materials e.g.- hard plastic, plastic-coated metals - waterjet cutting is almost the only applicable method - as it does not damage the surface.

Request for a quote

FLOW EUROPE GMBH

Germany

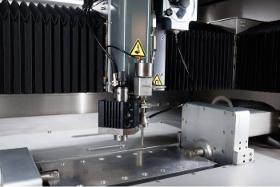

The Mach 3 series offers you the world’s most reliable ultrahigh-pressure pump, intelligent process monitoring, and an array of unparalleled options all integrated into the most powerful waterjet control available. This system configuration incorporates a design that combines the motion control, pump and high-pressure components into one compact machine. It consumes minimal floor space, provides excellent operator access, and is configured for easy material loading and unloading.

Request for a quote

URM - UNIVERSAL RUBBER MANUFACTURING NV

Belgium

URM offers a broad range of silicone grades to produce custom rubber silicone die cut and waterjet cut gaskets that meet exact customer specifications. At URM, all silicone grades are available as thin as .008 thick to 1″ thick and are offered in continuous rolls or cut to meet your precise requirements. More information All silicone grades come in a measure of hardness (durometer) as soft as 25 durometer, and as hard as 80 durometer. Standard colors include orange/red, black, gray, and white; special colors are available upon request. Industry use Silicone is particularly suitable for UV and ozone affected applications and can be used up to +230 ºC.

URM - UNIVERSAL RUBBER MANUFACTURING NV

Belgium

Cellular rubber is expanded black rubber material with closed cells. Cellular rubber has a lower permanent deformation value than polyethylene foam Available in densities from 90 450 kg/m³. doneAvailable in blocks up to 60 mm thick, depending on the type doneAvailable in rolls with adhesive. More information Cellular rubber are used for static sealing , shock absorbtion, and dampening material in all types of industry earth moving equipment, automotive industry, cab trimming, ventilation, building industry, etc.. Gaskets and flat sealings are produced through die cutting (for high volumes), or by waterjet cutting (for lower volumes and prototyping) Industry use oil and fuel resistance, chemical resistance, temperature resistance, flammability , weather resistance, compression set, compression deflection

MARXAM PROJECT

Poland

Water jet cutting services allow to ensure high quality of the machined surface for details with large thicknesses and complex geometric shapes (high density of cutting lines on a small area, small diameters of holes – of even 1mm). The use of aqua cutting with high pressure, containing fine abrasives, allows to achieve new production effects, which were impossible or time-consuming and expensive using other methods. Using this method, we can process, materials such as: - Ceramic materials - Glass - Plastics - Titanium and its alloys - Materials sensitive to high processing temperatures - Structural, alloy and tool steels (of any degree of hardening) - Cast iron, steel - Copper, brasses, bronzes - Molybdenum and its alloys - Wood and wood-based materials Waterjet cutting technology is one of the most environmentally friendly processing methods. The abrasives used are of natural origin and are chemically inert, and the process itself does not generate any harmful waste.

Request for a quote

TEKNO KESIM

Turkey

custom and contracted manufacturer process for eva foam cutting about tool and medical industry and more. CNC foam cutting machine enables quick and cost-effective hole milling service. For mass production, cost-effective mold press cutting is also available. Soft urethane foam or harder polyethelene foam are also available. For custom cutting, harder polyethelene foam is used.

TEKNO KESIM

Turkey

olyurethane (PU) Foam Insert Custom molded polyurethane (PU) foam inserts are the perfect choice for protecting your products against damage due to its high shock absorbent characteristic while creating a luxury look and feel. In addition, PU foam is an excellent choice for its lightweight and compressible (easy to store) nature. this could be also eva foam. or flocked foam insert for medical usage and pe foam for electronic and toolindustry

TEKNO KESIM

Turkey

we use standard EVA foam with a 75 Kg/m3 density. It has a 5–100 Shore A hardness. It is produced as a plate of 1000 x 1500 mm. Thickness of EVA plates starts from 1,5 mm and goes up to 38 mm which fits our EVA cutting process very well. As it has a high temperature tolerance, it can be molded by heat (thermo-form). EVA foam is resistant to heat starting from -40° C till + 90° C . It is a soft and flexible material. It can be with design on it. It is waterproof. It is antibacterial, free of hazerdous chemicals. It is available in various colors. As Tekno Kesim, we do EVA cutting for you by laser, cnc, waterjet or die cut for eva foam cutting. We have mentioned above the characteristics of EVA and due to these and the area you need to use, EVA cutting is prefered. As it has a very good suction ability, for sensitive items and electronic devices we make case inserts or box seperators by EVA cutting. It has many advantages like providing high protection and stylish appearance.

MECANUMERIC

France

Pure water jet cutting machine MDE range allows VHP pure waterjet cutting. Available with different pumps and options, it is designed mainly for tissu and leather industries. Structure : - frame single block in welded steel - mobile gantry in welded steel - stainless steel tank - plastic or aluminum honeycomb coating - 3-turn rotary table for cutting / loading and simultaneous nesting / unloading (MDE-R only) Kinematics : - guidance by stainless steel precision linear rails with preloaded ball slides - XYZ transmission by pre-loaded ball screws (double X-axis motorization) - motorization by AC brushless motors - rotative table with cross-roller crown (MDE-R only) Numerical control : - Numerical control MECANUMERIC CN7000 ISO with 40 Gb hard disk - MHI on control desk with a 15-inch touch screen - Data input by Ethernet link, USB port Features : TYPE MDE MDE-R X-axis travel in mm 1005 1050 Y-axis travel in mm 755 750 Z-axis travel in mm 75 50 Max. speed in mm/sec 30...

Request for a quote

BFT GMBH

Austria

INCREASE THE PRODUCTIVITY OF YOUR EXISTING WATERJET CUTTING SYSTEMS BY AT LEAST 30 % With HYPERTRON®, you can reach a 30 to 50 % higher cutting speed and energy efficiency combining servo technology with ultra-high pressure. The HYPERTRON® provides flow rates of 3.5 l per minute with 6,000 bar or 4.6 l per minute with 4,000 bar. Whether you want to work with two cutting heads or only with one cutting head, HYPERTRON® provides the right pressure – from 100 to 6,000 bar. Flexibility and high performance in one. Customers buy European products… because they are adjusted to the requirements of European companies. because they are designed taking into consideration a responsible treatment of our resources. because they are easy to service and all common metrical tools match. because they meet European standards and quality expectations.

Request for a quote

BFT GMBH

Austria

THE NEXT STEP IN PUMP TECHNOLOGY EVOLUTION: ENERGY-SAVING, HIGHLY EFFICIENT AND PROFESSIONAL. SERVOTRON® is available in the power classes 37 kW and 45 kW. Its operating pressure of 4,000 bar has been considered to be the optimum in the professional waterjet cutting sector for years. The Austrian technical control board has confirmed that up to 24% energy can be saved with SERVOTRON® in a comparison with conventional pumps. It is available with a flow rate of 3.8 l per minute and 4.6 l per minute. Customers buy European products… because they are adjusted to the requirements of European companies. because they are designed taking into consideration a responsible treatment of our resources. because they are easy to service and all common metrical tools match. because they meet European standards and quality expectations.

Request for a quote

ANT APPLIED NEW TECHNOLOGIES AG

Germany

Facing new manufacturing challenges? Want to be quicker and more precise than your competitors? Then you need ConSus. The ConSus system is an Abrasive Mixing Unit (AMU) in which abrasive is added continuously to the pressurized water flow with the worldwide patented lock method. High capacity and low pressure have been unachievable in water jet cutting until now. That’s exactly what the Water Abrasive Suspension (WAS) cutting method from ANT delivers. Tests prove: The ANT suspension jet cuts two to three times faster than conventional water jet cutting methods and at less than half the pressure. The reason for this is the composition of the water jet - a suspension made of water and an abrasive, which is pressurised without air before being squeezed out of the nozzle. The omission of air allows the jet to cut much more efficiently. ConSus combines all of these benefits in a single unit, which can be integrated into any existing water jet cutting system.

Request for a quote

ANT APPLIED NEW TECHNOLOGIES AG

Germany

Mobile water jet cutting unit particularly suited for Defusing large-caliber fund munitions EOD (Explosive Ordnance Disposal) & IEDD (Improvised Explosive Device Disposal). Environmental exposure over the time has chemical and/or physical effects on ammunition & often leads to a critical in-situ situation of the UXO. Conventional Render Safe Procedure (RSP) is very often not feasible without contacting or shifting the UXO and therefore is considered as not secure. In such situations repeatedly it came to severe accidents with death tolls. Hence safety of transport to carry-off for final removal is also not given.Therefore in such cases blasting the UXO is so far used as a final RSP causing partly heavy collateral damages. This unit allows to remove or deactivate the fuse remotely, risk-free & safe by using the WAS Technology & specially designed manipulation systems. The deployment of this technology around the globe has become state of the art today and is an accepted RSP world-wide

Request for a quote

ANT APPLIED NEW TECHNOLOGIES AG

Germany

The mini MACE is suited for, for example, the cutting and opening of pipe bombs, hand grenades or potentially hazardous objects such as unconventional explosive devices in the form of fire extinguishers and cases. mini MACE combines an abrasive mixing unit and a high-pressure pump in a single casing. The working pressure of the unit, which is driven by an internal combustion engine, is 6525 PSI (450 bar). The mini MACE was developed as a mobile penetration and cutting tool. An autarkic complete system equipped with internal combustion engine, abrasive mixing unit (AMU) and high pressure pump for accessing and deactivating IEDD (Improvised Explosive Device Disposal). It could be also used in the industrial sector for e.g. opening tanks.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BLASQEM, LDA.

Portugal

Natural garnet sand is a non-active mineral abrasive which does not cause silicosis. It has high performance, ensuring efficiency and economical process with medium oxidation level. Its grains are microcrystalline, with more or less irregular rounded shapes. Hardness: 6-7.5 mohs Shape: irregular Density: 3.5-4.3 g / cm3 Welcome to BLASQEM, your Specialist in Shots, Abrasives and Equipment: - Abrasive Products and Accessories - Abrasive steel shots - Abrasives manufacturer - Abrasives solutions - Blasting material - Metallic shots and organic media or glass sandblasting and aluminium oxide or carbon grit abrasive shots for shot blasting - Steel Abrasives and aluminium shot for shot blasting operations - Blasqem is the industry's leading supplier of industrial abrasive

Request for a quote

FINEPART SWEDEN AB

Sweden

Finecut 3-Axis Waterjet Machine, a Premium Micro Abrasive Waterjet, Beyond Cutting Edge. Cutting width down to 0.2 mm Designed for ultimate precision cutting Highly dynamic and fully encapsulated motion system Flexible fixtures for different applications Intuitive HMI Easy set-up. Easy to operate. Easy to service. Ultra-High Precision Water Jet Cutting Machine – with Finecut™ WMC 500 II Waterjet Machining Center … BEYOND CUTTING EDGE Micro Abrasive Waterjet technology is the proprietary cutting system of Finepart. It was developed to accompany the Finecut Waterjet Machining Center and together they bring the waterjet technology to a whole new level of precision cutting. The micro abrasive waterjet process is a particle erosion based, non-thermal cutting process. This process can cut virtually all materials and produce an excellent surface finish that does not change the material properties.

Request for a quote

FINEPART SWEDEN AB

Sweden

Finecut 5-axis waterjet cutting machine is a premium micro abrasive waterjet, for fast cutting without taper. Ideal for volume manufacturing purposes Ideal for cutting complex shapes Cutting width down to 0.2 mm 5-axis cutting with tool center point control Corner optimization by waterjet motion strategy Compared to traditional cutting methods, the 5 axis waterjet technology has the cutting edge capabilities of combining increased cutting speed, ultra high precision, and three dimensional cutting, with taper elimination, into ONE cutting edge waterjet machine, the Finecut WMC500II Ideal for volume manufacturing purposes Cutting twice as fast, compared to 3 axis cutting Ideal for applications that requires complex cutting 3D abrasive cutting capabilities Ultimate taper control and taper elimination Able to cut materials both soft and hard materials

Request for a quote

FINEPART SWEDEN AB

Sweden

High Speed Complex Precision 5 Axis Waterjet Cutting Technology, Ideal For Prototyping Ideal for prototyping or one-off parts and cutting highly complex shapes, with cutting width down to 0.2 mm. 5-axis cutting with tool center point control and corner optimization by waterjet motion strategy. Cutting width down to 0.2 mm 3 dimensional cutting 5-axis cutting with tool center point control High inclination angles and complex shapes Perfect for prototyping FINECUT MICRO ABRASIVE WATERJET TECHNOLOGY Advantages and Capabilities Increase Your Productivity, Cutting Speed, Precision, While Doing Complex Cutting. Ideal for prototyping Ideal for applications that require complex cutting 3D abrasive cutting capabilities Cutting 2X as fast, compared to 3 axis cutting Ultimate taper control and taper elimination Able to cut materials of almost any kind, both soft and hard materials

Request for a quote

FINEPART SWEDEN AB

Sweden

Finecut 4-Axis Waterjet Machine, a Micro Abrasive Waterjet, Beyond Cutting Edge. Precision with rotating work piece 4 axis working synchronously Cutting width down to 0.2 mm Live fixturing for cutting part from different sides Rotates workpiece synchronously with cutting High inclination angles Utilizes 5-axis control with tool center point function Cutting With 4 Axis Rotary Table The A-axis can be fitted with a work table plate on which any work piece can be placed. With this mechanism the part can be reoriented to provide access for cutting from different sides of the part. This motion system setup allows the waterjet nozzle to cut along a contour, following the part’s 3D curvature, moving all four axis in synchronous motion. Easy CAD/CAM Programming The machine has a 5-axis waterjet controller with capability for tool center point programming. All these operations are easily programmed using the CAD/CAM software provided with all Finecut waterjet machines.

Request for a quoteResults for

Waterjet cutting - Import exportNumber of results

23 ProductsCountries

Company type

Category