- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wall spray booth

Results for

Wall spray booth - Import export

FINIXA BY CHEMICAR

Belgium

Easy peelable coating for the protection of spray booth walls against overspray. Apply with a spray gun (2.5mm nozzle) in only 1 coat. (We suggest using our SPG 80+81). Bidon of 5L fits perfectly in SPG 80. When dried, powerpeel can’t be removed with water. This makes it possible to apply a coating from our CBP (active for 10-12 weeks). When the CBP has dried up, peel both layers off at once. Effortlessly protect your spray cabin walls with our peelable coating.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Water-sprinkled spray walls and spray booths with automatic paint sludge filtration system In wet separation, the overspray meets the water film of the spray wall and is thereby bound in the water. The sludge formed by this is discharged using sludge filtration systems. Water-sprinkled spray walls The overspray is sucked in in the lower area of the vertical water drain surface and is bound in water when it meets the film of water. The paint mist is washed out further in the lower section of the washout tower using a vortex washing system with downstream baffle plate separator. In order to replace the water lost due to evaporation, it is recommended to fit an automatic water level controller. The entire quantity of water is fed to the automatic paint sludge filtration system via the disposal pump. A coagulant is added to the water by an automatic dosing unit, as a result of which the paint sludge in the circulating water is disbonded and can be separated more easily. The cleaning of the circulating water takes place in the separately arranged paint sludge filtration system. Depending on the paint system and plant version, the separation system is operated using a full or partial current method. Water-sprinkled spray walls/booths with underfloor paint mist extraction For the painting of large parts with a high paint throughput. The paint mist is sucked in under the grating cover. A substantial part of the overspray is already bound in the water by the constant sprinkling of the entire floor of the basin. The paint mist is washed out further in the lower section of the washout tower using a vortex washing system with downstream baffle plate separator. Optimum capture of the paint mist is guaranteed by the laminar air flow inside the booth. A further advantage over comparable systems is the low water basin height and the associated low foundation depth. The sludge formed by this is discharged using sludge filtration systems. Advantages

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

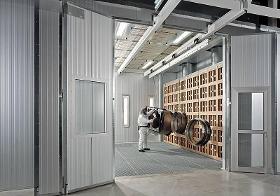

Spray walls and spray booths with dry separation via cartons. For lower utilisation times or overspray quantities RES dry spray booth For lower utilisation times or smaller overspray quantities, spray systems with dry separation offer a meaningful alternative to water-sprinkled systems. The Rippert modular spraying system type RES enables individual adaptation to the respective case of need. The filter system of the RES dry spray wall consists of individual square cardboard boxes. A sheet metal frame serves as a support structure for the filter box. In order to save costs, there is a possibility to vary the individual filter boxes in the spray booth, without exchanging all of the filter elements. Function The overspray is caught by the exhaust air stream and fed to the filter. The solids are filtered out here, while the cleaned exhaust air is blown out into the open air by the fan. Versions The basic version consists of a wall with a two-fold filter stage. Paper filter boxes form the first filter stage. A glass fibre fine filter arranged directly behind it represents the second filter stage. The attached radial fan is equipped with spark protection in the suction nozzle as well as an explosion-proof motor. The spray booth can additionally be equipped with removable or fixed side and ceiling panels. The RES dry spray booth is available in galvanised sheet metal or in stainless steel. Advantages Cleaning / maintenance The spray wall is designed such that the filter elements can be exchanged with little effort in a very short time. Once it is saturated, the filter box is removed from the sheet metal frame and disposed of in an environmentally-friendly manner.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Spray walls and spray booths with dry separation via pre-filters and fine filters. Spray walls and spray booths with dry separation For lower utilisation times or overspray quantities, spraying systems with dry separation offer a meaningful alternative to water-sprinkled systems. The Rippert modular spraying system type RTS enables individual adaptation to the respective case of need. Function The overspray is caught by the exhaust air stream and fed to the filter. The solids are filtered out here, while the cleaned exhaust air is blown out into the open air by the fan. Versions The entire spray wall and the drip tray are made of galvanised sheet steel. The basic version consists of a wall with a two-fold filter stage. The attached radial fan is equipped with spark protection in the suction nozzle as well as an explosion-proof motor. The first filter stage is formed by a paper filter or a baffle plate filter, consisting of two rows of galvanised sheet metal lamellae arranged one behind the other. A glass fibre fine filter arranged directly behind it represents the second filter stage. The spray wall can additionally be equipped with removable or fixed side and ceiling panels. Each version is also available with floor suction pan, available with an integrated 2-stage filter and grating cover. Accessories In addition, the spray wall can be equipped with various accessories from the Rippert product range, such as explosion-proof lights, energy-saving flaps, turntables, etc. We recommend the installation of a supply air system for the replacement of the exhausted air. Cleaning / maintenance The spray wall is designed such that the filter elements can be exchanged with little effort in a very short time. For faster cleaning, baffle plate filters should by sprayed with a release agent (e.g. strippable varnish) before being put into operation. Underfloor paint mist extraction With dry separation, consisting of a support structure with attached paper filter, grating cover and a suction duct with air quantity adjustment.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Standard advantages: RTS-Rotation – low-maintenance dry spray booth Overspray dry separation demonstrates its strengths in practice above all when relatively large quantities of paint have to be processed and the overspray portion cannot be reduced any further. Spray booth with dry separation are usually equipped with disposable filters or manually regenerative filters. These cause costs for spare filters, maintenance and disposal. In addition to that, operation has to be interrupted in order to exchange the filters. The ‘RTS rotation’ system was developed by Rippert in order to reduce these costs and tooling times. Maintenance intervals and filter service lives are prolonged significantly in comparison with conventional systems due to the new brush pre-filtration. How the ‘RTS-Rotation’ system works Overspray separation in the RTS-Rotation system takes place by means of a pre-filter and a fine filter stage. The pre-filter stage is formed by vertical, slowly rotating brush rollers. The bristles present a very large total surface area and absorb the adhesive particles from the overspray. During the slow rotation, the paint particles can dry on the tips of the bristles. This results in slowly growing cakings on the bristles. Scrapers are mounted in the area behind the brush rollers that continuously remove these cakings from the bristles. The dislodged, hardened material falls into the drawers arranged under the brushes and can thus be simply disposed of. The dry paint dust may often be disposed of as ‘commercial waste’. The brushes otherwise require little maintenance and do not need to be exchanged or renewed. The fine filter stage is formed by a special fleece filter, which is arranged above the brush rollers and must be manually maintained or exchanged in the standard version. The maintenance intervals depend on the paint material used. Automatic cleaning or an external fine filter with automatic cleaning is also possible as an option. Over 10 years of operational experience shows that around 75 to 95% of the overspray is separated out by the pre-filter stage and the rest by the fine filter stage. The degree of separation depends strongly on the type of paint and the drying reactivity during the flying phase. Use of the RTS-Rotation with the following paints Before practical use, the paints are tested and approved in Rippert’s own pilot plant. Stove enamels and 100% UV paint systems cannot be used. The horizontal version Furthermore, it is possible to use the system as a horizontal underfloor extraction system. This version is used, for example, by a machine manufacturer for large parts. In addition, a drag conveyor with gulley extraction is used there in order to automatically transport the particles cleaned off the brushes out of the pit. Conclusion The RTS-Rotation system is particularly useful when relatively large quantities of paint with an unavoidable overspray portion have to be processed, as otherwise a great deal of residual waste would result using conventional technology. Compared to water-sprinkled spray walls and normal dry spray booths the amortisation period is shorter; it is frequently less than two years.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VOGAMAKINA INDUSTRIAL PLANTS LTD. CO.

Turkey

Combined spraybooths are designed for manual painting application for automotive industry with downdraft ventilation and drying system. It is manufactured from insulated panel body. Installed to the factory ground or to an metal basement, extraction air ducts are placed at the ground, Fresh air plenum and filtering system is located at the ceiling that creates clean environment inside the spray booth during the painting and drying application. Painting or drying option are selected manually from the control panel, flash-off and cooling positions are automatically controlled. Includes standard type illumination system and optionally Ex-zone, electrical control panel and wiring to the control panel is done. The spray booth is fully controlled by PLC control system and a touch panel. Control system indicates when filters gets contamnated. Filters are easy replaceable. The spraybooth is CE certificated and conforms to the European Norms.

Request for a quote

VOGAMAKINA INDUSTRIAL PLANTS LTD. CO.

Turkey

The spraybooth is designed for manual painting application, with sidedraft ventilation and dry cardboard filtration system. The benefit of the retractable liquid spray booth is that it is an extendeable and saves space in the workshop at folded position during it is not used. The spray booth is environmentally friendly.

Request for a quote

GZ GUANGLI EFE CO., LTD.

China

Features 1.All steel construction raised basement; 2.Full downdraft airflow style, ensuring turbulence-free airflow path; 3.Illumination brightness reaches 1200 lux; 4.Oil fuel heating (gas-fired heating, electric central heating, hot water heating and steam heating are optional); 5.Sheet metal is processed to European standards; Standard Configurations -Basement: all steel construction raised basement, 5-row grating; -Fan unit: one 7.5kw intake fan, one 7.5kw exhaust fan; -Heating: Riello RG5D burner, with heat exchanger; -Lighting system: upper lights are 14*4*13W LED light tubes, lower lights are 10*4*13W LED light tubes; -Wall panel: sheet metal is molded by one-step process, four-side edge banded rockwool insulated wall panel, thickness 50mm -Ceiling structure: 14 pieces of precision punched steel panels -Roof panel: double-skin insulated roof panel -Electric control: imported electrical components, phase loss protection, overheat protection and overload protection

Request for a quote

GZ GUANGLI EFE CO., LTD.

China

Features -All steel construction raised basement; -Full downdraft airflow style, ensuring turbulence-free airflow path; -Illumination brightness reaches 1000 lux; -Oil fuel heating (gas-fired heating, electric central heating, hot water heating and steam heating are optional); Standard Configurations -Basement: all steel construction raised basement, 2-row grating+3-row checkered plate; -Fan unit: one 5.5kw intake fan, one 5.5kw exhaust fan; -Heating: Riello G20 burner, with heat exchanger; -Lighting system: upper lights are 8*4*18W LED light tubes, lower lights are 8*2*18W LED light tubes for option -Wall panel: EPS insulated wall panel, thickness 50mm; -Ceiling structure: welded ceiling frame; -Roof panel: single-skin galvanized steel roof panel; -Electric control: phase loss protection, overheat protection and overload protection, direct starting of motor;

Request for a quote

ENDUSTRI GM

Turkey

In order to achieve the desired quality in wet paint application, the main standards that must be fulfilled in the facilities are appropriate filtering and clean air system, suitable air conditioning and appropriate lighting. The electrical equipment in the painting facility must be suitable for the explosion document. Filtration systems must comply with the regulations of the Ministry of Environment waste gas emission values.

Request for a quote

GZ GUANGLI EFE CO., LTD.

China

Features -All steel construction raised basement; -Full downdraft airflow style, ensuring turbulence-free airflow path; -Illumination brightness reaches 1000 lux; -Oil fuel heating (gas-fired heating, electric central heating, hot water heating and steam heating are optional); Standard Configurations -Basement: all steel construction raised basement, 2-row grating+3-row checkered plate; -Fan unit: one 7.5kw intake fan, one 5.5kw exhaust fan; -Heating: Riello G20 burner, with heat exchanger; -Lighting system: upper lights are 10*4*18W LED light tubes, lower lights are 8*2*18W LED light tubes; -Wall panel: Rock wool insulated wall panel, thickness 50mm; -Ceiling structure: punching ceiling frame; -Roof panel: single-skin galvanized steel roof panel; -Electric control: phase loss protection, overheat protection and overload protection, direct starting of motor;

Request for a quoteResults for

Wall spray booth - Import exportNumber of results

12 ProductsCountries

Company type