- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vibratory conveyors

Results for

Vibratory conveyors - Import export

HO-MA GMBH

Germany

1-lane infeed with distribution on 3 lanes for blow-fill products 3-lane infeed with distribution on 6 lanes for vial adapter products

Request for a quote

HO-MA GMBH

Germany

With vibration sorting, small batches / quantities can be processed individually up to 200 pieces per minute. Depending on the type of object, we recommend different designs / types – conical, cylindrical or stepped. Surfaces are preferably glass bead blasted or metaline coated (both variants have FDA approval). Mounting types are medium voltage and external voltage.

Request for a quote

VCSP LTD

United Kingdom

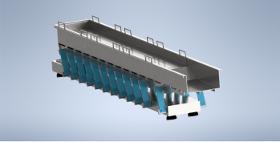

VCSP's Vibratory Laning and screening Conveyors are the epitome of precision and efficiency. Expertly engineered, they ensure exact product laning and screening capabilities. By harnessing the power of vibration, these conveyors align products perfectly. Customizable to diverse needs, they fit various product types and capacities. Key features include adjustable vibration settings, a range of surface finishes, and energy-efficient designs. Built for durability, they promise longevity even in demanding industrial settings. Their user-friendly design ensures easy maintenance, while their adaptability allows for integration into existing production lines. Ideal for robotic pick and place, automated assembly, packaging lines, and quality control, VCSP's Vibratory Laning Conveyors are the answer to precise product handling and alignment

Request for a quote

VCSP LTD

United Kingdom

VCSP excels in crafting specialized systems for the food industry. When it comes to mixing vegetables, our solutions are unparalleled. Using advanced vibratory technology, we ensure gentle handling, preserving the freshness and texture of each vegetable. Our conveyors are tailored to handle diverse vegetable types, from leafy greens to tubers, ensuring a consistent mix. The modular design offers scalability, perfect for varying production needs. With precision controls, we guarantee the right mixing ratios for a uniform blend. Hygiene is paramount; our systems are designed for easy cleaning, minimizing contamination risks. With VCSP, you get a reliable, efficient, and sanitary vegetable mixing solution.

Request for a quote

VCSP LTD

United Kingdom

VCSP's Vibratory Glazing Conveyors are at the forefront of product aesthetics enhancement. These state-of-the-art conveyors allow for precise application of water or oil, elevating the visual and tactile appeal of products. With unparalleled precision, they ensure uniform glaze distribution, resulting in products that resonate with brand identity. Beyond aesthetics, the glazing process can increase product weight, directly boosting operational efficiency and profitability. Customizability ensures the glazing process aligns with specific preferences, while seamless integration into existing production lines guarantees a smooth transition. With VCSP, experience a blend of visual allure, tactile satisfaction, and maximized yield. Our commitment extends beyond product delivery, offering comprehensive support from installation to ongoing maintenance

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MESUTRONIC GMBH

Germany

FOR THE DIRECT INSTALLATION INTO THE TROUGH OF A VIBRATORY CONVEYOR. Detects all metals encapsulated or as loose parts. Reliable machine protection through high detection accuracy. Quick and easy to install. Minimal investment. Customized solutions for all trough types and sizes. User friendly and reliable technology, proven for many years.

Request for a quote

MESUTRONIC GMBH

Germany

RESEPARATION SYSTEM INCLUDING CONVEYING, DOSING AND SEPARATOR UNIT • Metal separator QUICKTRON 03 R for reliable detection results • Adjustable vibratory dosing conveyor for regulating throughput • Hopper loader with suction lance for independent operation • Standardized system to fit industrial barrels or big-bags for material storage

Request for a quote

MESUTRONIC GMBH

Germany

TUNNEL METAL DETECTOR FOR INSTALLATION IN BELT CONVEYORS, VIBRATORY CHUTES, MATERIAL SLIDES AND DROP CHUTE Detects all metals encapsulated or as loose parts. High sensitivity in rough industrial environments. User friendly and reliable technology, proven for many years. A worthwhile investment that protects the valuable production equipment. Specifically tailored system solutions with reliable conveying technology and selected accessories.

Request for a quote

MESUTRONIC GMBH

Germany

DIVERTIBLE TUNNEL METAL DETECTOR FOR INSTALLATION IN BELT CONVEYORS, VIBRATORY CHUTES AND MATERIAL SLIDES. Detects all metals in solid products or as loose parts. High sensitivity in rough industrial environments. User friendly and reliable Technology, proven for many years. A worthwhile investment that protects the valuable production equipment. Quick and easy to install. Specifically tailored system solutions with reliable conveying technology and selected accessories.

Request for a quote

MESUTRONIC GMBH

Germany

SINGLE SURFACE METAL DETECOTR FOR INSTALLATION IN BELT CONVEYORS, VIBRATORY CHUTES AND MATERIAL SLIDES Detects all metals encapsulated or as loose parts. For medium bulk heights. High sensitivity in rough industrial environments. Reliable machine protection with little investment. User friendly and reliable technology, proven for many years. Quick and easy to install. Specifically tailored system solutions with reliable conveying technology and selected accessories.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

At IFA Technology we use all types of pumps available on the market for conveying liquids. We consider all necessary requirements for the safe and reliable conveyance of your products. Solids can be conveyed mechanically, pneumatically and hydraulically. For mechanical conveying, screws, conveyor belts, elevators, vibratory troughs or tube chain conveyors are used. Pneumatic conveying is mainly applied in the chemical and pharmaceutical industries as well as for conveying granulates in plastics processing and the food industry. The pneumatic conveyance process is carried out by suction and compressed air, i.e. by vacuum or positive pressure, and is mainly used when sensitive substances are transported. Heavy substances such as cement, sand or gravel are mainly transported by positive pressure.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

700-1000 tph Granite Crushing and Screening Plants are the latest facilities. The plants aim, particularly, in the processing of stone granites to high-quality aggregates with a variable capacity of 700 to 1000 tons per hour. These advanced plants have been engineered with primary crushers, secondary crushers, vibratory screening plants, conveyors, and feeders facilitating efficient crushing and screening. Where primary crushers in the plant reduce oversized granite rocks to smaller fragments, secondary crushers continue to refine the material one step further to the target sizes for aggregates. Thoroughly screened using vibrating screens, the aggregate fractions are then sized and classified according to sizes into the final product to a very high standard to every highly diversified usage in construction, infrastructure, and industry. Through processing granite stones in a systematic manner, such plants give high-quality aggregates that are used in different construction projects to

Request for a quote

ELMOR

Switzerland

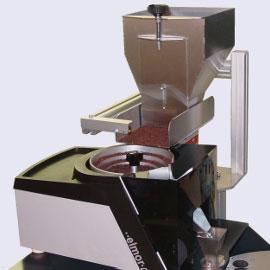

The feeding conveyor elmor 610 serves to refill the counting machines elmor C1, C3 or CX continuously and unattended. The feeding conveyor elmor 610 consists of a hopper, a feeding unit and a level sensor. Once the filling level in the conveyor bowl of the counting machine elmor C1, C3 or CX falls below a minimum value, it is automatically refilled through the feeding conveyor elmor 610. For small and light parts such as seeds, a linear vibratory conveying device is used. The hopper has 4 liters of storage volume. For large or heavy items refilling is done via a belt conveyor. The storage volume in this case is 10 liters or more. With the feeding conveyor elmor 610 a long operating autonomy is achieved, especially when the couning machine runs in combination with a filling or packaging machine. Technical data Suited for parts larger than 2 mm in diameter Type of conveyor: linear vibratory conveyor or belt conveyor Storage volume: 4 litres (vibratory conveyor) or 10 litres (belt conveyor) Level sensor: a precise sensor switches the conveyor on and off depending on the level to be regulated elmor Green Design Our label for: high energy efficiency longevity no standby power loss most components may be recycled production without solvents, ROHS conformity

Request for a quote

VCSP LTD

United Kingdom

The VCSP Electromagnetic Drive delivers optimal performance and efficiency to vibratory conveyors. With precision control, superior efficiency, and reliable durability, it enhances material handling operations using vibratory conveyors. Key Features: Precision Control: Customizable speed and amplitude adjustments ensure smooth and efficient movement of materials. Superior Efficiency: Advanced electromagnetic technology minimizes power consumption for cost savings and environmental benefits. Reliable and Durable: Built with high-quality materials, it guarantees exceptional reliability and longevity. Easy Integration: Seamless installation and user-friendly interface for effortless control and operation. Customizable Solutions: Tailored electromagnetic drives to meet unique material handling requirements. Experience the cutting-edge VCSP Electromagnetic Drive to enhance vibratory conveyors. Contact us for efficient, reliable, and cost-effective vibratory conveyors

Request for a quoteResults for

Vibratory conveyors - Import exportNumber of results

15 ProductsCompany type