- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- verticalization units

Results for

Verticalization units - Import export

LÖDIGE INDUSTRIES GMBH

Germany

The truck dock from Lödige facilitates the loading and unloading of air cargo units onto and off trucks. Equipped with a hydraulic lifting unit and a vertical shift function, the truck dock brings conveyor elements into line with the truck loading ramp. ULDs or pallets are transferred horizontally by a powered roller conveyor. Depending on requirements, the conveyor can be replaced or combined with other technologies such as a ball deck or castor deck. A moving version of the truck dock is also available.

Request for a quote

PRESSTA EISELE GMBH

Germany

0 – 300 mm adjustable pneumatic material feed and digital display Vertical hydraulic punching unit to the right of the saw blade Power 200 KN Punching tools according to profile shape Aluminium profile – finished Cut to length Vertical punching Up to 8 profiles in one operation cycle Cycle time from 13 s / 1,63 s each piece Layout of punching tools for multiple profiles Quick change punching tools according to the profile shape Pneumatic material feed 8 profiles at once Special shaped quick change support Clamps according to profile shape – changeable Hydraulic punching unit Power 200 KN, stroke 20 mm Cycle spray mist device for each die and for the saw blade

Request for a quote

APD MAQMASTER

Spain

Copy machine with vertical milling unit. Steel base Suitable for milling operations on aluminium profiles using a template or recess.

Request for a quote

APD MAQMASTER

Spain

Copier with vertical milling unit and 180° swivel table. Steel base and work table. Suitable for milling operations on aluminium profiles using a template or stop. The spindle speed can be electronically adjusted on the machine using an inverter. Adjustable swivel table also for intermediate grades.

Request for a quote

PRO DESIGN

Turkey

Wall-mounted displays are fixtures attached to walls within a retail space to showcase products, promotional materials, or branding messages. These displays maximize vertical space, allowing retailers to present merchandise at eye level for easy viewing and access. Wall-mounted displays can include shelves, hooks, digital screens, or graphic panels, offering versatile solutions for various product types. By keeping the retail floor uncluttered, they enhance the overall shopping experience and make navigation easier for customers. Effective wall-mounted displays are well-organized, aesthetically pleasing, and strategically placed to highlight key products and promotions, driving customer engagement and sales.

Request for a quote

PRO DESIGN

Turkey

Floor-standing banners are vertical display units positioned on the retail floor to convey promotional messages, branding, or product information. These banners are typically large, eye-catching, and strategically placed in high-traffic areas to maximize visibility and impact. Made from durable materials, they can withstand daily wear and tear while maintaining their vibrant appearance. Floor-standing banners are versatile, easy to set up, and transport, making them ideal for seasonal promotions, sales events, or new product launches. They effectively capture customer attention, enhance the shopping experience, and drive in-store engagement and sales.

Request for a quote

MARTIN GROUP SRL

Italy

double heating system with pre-heating that concurs to fuse with very low temperature respect to the standard temperature pressure system with “OUT” function for very delicate woven inside and outside belts cleaning devices carbon/graphite lower belt separation blade automatic turn ON and turn OFF by digital timer COUPLING, LAMINATION, TRANSFER, APPLICATIONS - COMPLETE LAMINATION LINE THAT CONCURS THE COUPLING OF 2 OR MORE LAYERS OF WOVEN WITH INTERLININGS, WEB GLUE OR FILM GLUE DIAGNOSTIC ON THE CONTROL PANEL introducion of the several rolls of wovens, interlinings, web glue or film glue by engine rolls perfect syncrony between fusing machine winding module and rewinding unit by inverter automatic cut machine availabilty for worked parts winding unit with vertical and horizontal control for a perfect alignment of the woven rolls during the winding fusing machine connected to the winding and rewinding module by inverter exit zone with rewinding unit equipped

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The automatic mitre bandsaws from BEHRINGER are saws to really get things moving. Particularly when it comes to classical series production such as cutting to fixed lengths and mitre sawing in automatic mode. And also when cutting layers and packages they make a good impression. By their excellent cutting performance and short nonproductive times, your productivity can be increased significantly. Using an NC controlled feed gripper in conjunction with an NC controlled saw frame mitre box, fully automatic mitre cuts can be performed on both sides. The PC control system provided as standard makes for extremely simple menu-prompted operation of the saw and peripheral devices. The BEHRINGER mitre bandsaws contain many useful features already in the basic price: - Convenient PC control - Fast NC-controlled mitre system - Vertical clamping unit - NC-controlled feeding gripper with 3.000 mm feeding length in single stroke - Spray mist cooling system

Request for a quote

SOPEM

Belgium

Year - 1991 Contiweb splicer + 3 doctor blade flexo print units + window + vertical drying station with infra-red

Request for a quote

TECNO IMPIANTI SRL

Italy

The pre-feeding units Model INT are utilized for bringing medium-big diameter wire to the nextmachine, when the uncoiler is of the vertical axis type. These units can work with in-line wire drawing machines, cold heading machines, wire drawingbull-blocks.They are equipped with two feed rolls and a series of straightening rolls.At the exit of the machine can be installed a cut-off unit.

Request for a quote

MOSCA GMBH

Germany

KZV-111 BASIC MODEL - Top-mounted sealing unit - 1 KSR sealing unit and 1 vertical arch - Moveable strap lance for strapping palletized goods - 1-column construction up to 2,000mm - 2-column construction up to 2,000/2,400 mm with pressure Stretch wrapper - Turntable diameter Ø 1,800 or 2,200mm - Max. load for turntable: 3,000 kg weight and pressure - Max. pallet size according to turntable dimensions - Max. wrapping height (incl. pallet): 2,400mm - Optical sensor for pallet height scanning - Soft start and soft stop for turntable frequency controlled - Frequency controlled speed of the turntable - Frequency controlled speed of the lift slide - Turntable stop in starting position - Easy to operate

Request for a quote

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

Our coating line concepts stand for maximum production output, low energy consumption and highest precision regarding temperature distribution, air circulation and coating application. We can offer many different coating application units, such as combined floating knife/ cylinder coating head, knifeonrubberblanket coating unit, magnet roll coating unit, paste dot or screen coating unit, powder scatter coating assembly, kissroll unit, impregnation bath, reverseroll coating unit and vertical floating knife coater. Our lines are used for coating many kind of end products, such as airbags, automotive interior, truck tarpaulin, architectural fabric, protective clothing, emery cloth, paragliders, awning cloth, billboards and many others.

Request for a quote

VILLINA LLC

Russia

Villina-GNVCP-2T type vertical electric semi-submersible pumping units are designed for transit in stationary conditions of neutral, corrosive, toxic, as well as explosive and fire hazardous liquids, the vapors of which can form explosive mixtures with air. These are used in gas, petrochemical, petroleum refining and other industries. The vertical semi-submersible pump – the pump part is fully or partially in the pumped liquid. The unit consists of a pump part, drive sections, a base plate, a device that transmits torque from the drive, an electric motor (drive). The ground part comprises a console fastened to the base plate, an electric motor mounted and fastened to the console, and a mechanical seal support system fastened to a base plate. The semi-submersible part comprises drive sections fastened to the base plate, an elastic coupling body connected to the lower drive section, a pump connected to the elastic coupling body and a discharge line.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

With a capacity of up to 2500 pieces of baggage per hour, strength and resilience are fundamental. The Motion06 Vertical Sorting Unit Belt Conveyor is used for the distribution and merging of baggage and general cargo between two or three levels. The belt conveyor incorporated into the Vertical Sorting Unit is height adjusting using a top of the line lifting system with two steelreinforced tooth belts. This maintenancefree lifting system has been tried and tested for decades. It is also possible to use it in flight baggage systems with a container system. The belt conveyor is replaced by an appropriate conveyor element for this purpose. Any Height Requirements Ultrasimple adjustment for the required input and output positions. No Maintenance Maintenancefree lifting system thanks to lifetime lubricated bearings and optional toothbelt drive.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

Overcome heights, safely and precisely. With its precise and efficient lifting unit, the Vertical Transporting Unit performs a real show of strength – with ease! The belt conveyor element incorporated into the baggage lifter is raised and lowered precisely using a lifting unit with two steelreinforced tooth belts. This maintenancefree lifting system has been tried and tested for decades. Between the two upper and lower end positions, any intermediate destinations can be reached. It is also possible to use the Vertical Sorting Unit in flight baggage systems with a container system. An appropriate Motion06 or FMH conveyor can be incorporated to work with the lifter. VTU – 420/660 Low Starting Height Low overall starting height possible. Any Height Requirements Ultrasimple adjustment for the required input and output positions. No Maintenance Maintenancefree lifting system thanks to lifetime lubricated bearings and optional toothbelt drive.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Ideal for use in refuse-derived fuel (RDF) incineration plants for the handling of materials such as wood chips, shredded plastic or tires, paper and cardboard scraps, pellets and/or fluff. Mainly used in cement, paper and industrial plants (high heat-value areas). Technical design Optimisation of crane load capacity thanks to its lightweight design which can hold maximum loads Both motor grab systems (MZG and MMGM) can be made fully automatic by attaching sensors MZG is ideal for use in tight spaces Lightweight design for high load capacity Size, measurements and grab suspension can be customised according to your needs Further advantages: see type MZG port and type MMGM (under “products/motor grab systems) Grab drive Vertical electrohydraulic drive unit with high-pressure pump Turn control or valve control

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

METZEN INDUSTRIES GMBH

Germany

Waste incineration plants, refuse-derived fuel (RDF) incineration plants or incineration plants of any kind. For various types of cranes which operate using hooks or rope/chain suspension. Technical design Open shell design Suitable for handling all kinds of waste Optimisation of crane load capacity thanks to its lightweight design which can hold maximum loads Self-locking grab suspension for crane hooks Grab drive: Vertical electrohydraulic drive unit with high-pressure pump Closing and opening movements are controlled through clockwise or counter clockwise rotation of the electric motor (turn control). The electric motor is only switched on whilst the closing and opening movement is being performed. Closing and opening movements controlled by directly connected hydraulic cylinders, with stable piston rod protection Grab connection bearing: Re-greaseable, robust steel bushing bearing KRÖGER MAINTENANCE-FREE bearing system Stable shell structure with shells made out of S355J2+N

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Handling general scrap, car bodies, steel chips, shredder scrap, paving stones and much more, in sea and inland ports or at storage facilities. For pier engineering and riverbed maintenance. For various types of cranes and excavators with internal or external holding cables. For various types of crane with control systems designed for hydraulic motor grab systems. Technical design Open, half-closed or closed grip design Suitable for handling scrap, stones, waste and other difficult to grab goods depending on design Optimisation of crane load capacity thanks to its lightweight design which can hold maximum loads, self-locking grab suspension for crane hooks Grab drive: Vertical electrohydraulic drive unit with high-pressure pump Closing and opening movements are controlled through clockwise or counter clockwise rotation of the electric motor (turn control). The electric motor is only switched on whilst the closing and opening movement is being performed. Grab connection bearing:

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Bulk handling of any kind in sea and inland ports or storage facilities. For ship-to-ship, ship-to-storage/wagon/silo handling. For various types of crane with control systems designed for hydraulic motor grab systems. Technical design Designed as a discharge and ship unloading grab with retracted pivot bearings for easy gripping under the ship’s gangway Optimisation of crane load capacity thanks to its lightweight design which can hold maximum loads Grab drive: Vertical electrohydraulic drive unit with high-pressure pump Closing and opening movements are controlled through clockwise or counter clockwise rotation of the electric motor (turn control). The electric motor is only switched on whilst the closing and opening movement is being performed. Grab connection bearing: Re-greaseable steel bushing bearing Stable, torsion-resistant design using direct cylinder linkage

Request for a quote

IMOBERDORF AG

Switzerland

The imo-smart is a highly-flexible, versatile rotary transfer system. 4 to 16 machining stations with up to 22 or more spindles ensure fastest setup times. The imo-smart provides you with a ready-to-use machining solution, tailored to your specific requirements and with a wide range of applications. The parts feed is carried out from bar stock, by means of load handling, robot or manually. With a reproducibility of ± 0.003 millimetres, the imo-smart is one of the most precise rotary transfer machines in the world. The imo-smart is designed to be a highly flexible and versatile solution. The excellent accessibility allows adjustments to be made in record time. The 3-axis E-80-CNC unit meets the most common needs: drilling, milling, reaming and tapping. It can be equipped with two spindles and installed horizontally or vertically. This unit can also be used on the imo-compact and the imo-space

Request for a quote

IMOBERDORF AG

Switzerland

On an area of only 9 square metres at a height of 2.30 metres, the imo-compact unites to form a complete, highly-productive rotary transfer system: The imo-compact controls 4 to 8 machining stations with up to 14 spindles per CNC. The parts feed is carried out optionally from bar stock, by means of load handling, robot or manually. The reproducibility of ± 0.003 millimetres makes the imo-compact one of the most precise rotary transfer machines in the world. The imo-compact unites all the elements of a rotary transfer machine. Even the smallest platform offers optimum accessibility. The 3-axis E-97-CNC unit meets the most common needs: drilling, milling, reaming and tapping. It can be equipped with two spindles and installed horizontally or vertically. This unit can also be used on the imo-smart and the imo-space The imo-rot corresponds to the 4th axis: the C-axis

Request for a quote

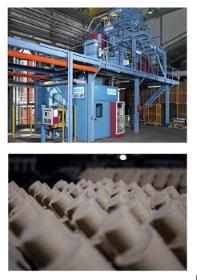

KUTES METAL

Turkey

1 unit DISA 40 L. Core Machine 1 unit hottinger 25 L. Vertical Core Machine 1 unit hottinger 20 L. Vertical Core Machine 3 unit hottinger 12 L. horizontal Core Machine Laempe 9 ton/hour Sand Mixer Laempe 5 ton/hour Sand Mixer Laempe Sand Dosing Unit Laempe Central Amine GAs Unit Lazyou Double COnveyor Core Drying Oven

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The KF192E is an industrial robot manufactured by Kawasaki. It has a payload wrist of 12kg and arm of 20kg and has a horizontal reach of 1,973mm with a vertical reach of 2,887mm. The unit has a maximum painting speed of 1,200mm/s and a body weight of 690kg. It has a floor mounting position, and a Bend Bend Roll (BBR) type of wrist.

Request for a quote

TAMA AERNOVA SRL

Italy

Model with pallet swap Data sheet The cutting shuttle table used to support the metal sheet must be integrated into the laser and plasma cutting machine. It is equipped with a drive system that follows the laser head to focus the suction of fumes and dust in the sectors affected by the cut. Its installation ensures the quality of the production environment and the protection of those who work there. Benefits This model with automatic pallet swap is composed of two sliding pallets driven by a chain drive, a hydraulically driven external lifting unit that allows vertical pallet change from a air suction segment table with trimming collection drawers which can be extracted from the side. The laser cutting downdraft table is interfaced with automatic load/unload cells and it is composed of pre-assembled modules, easy and quick to install. Standard equipment tanks with suction segments plate support grid leveling feet position sensors

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The RS050N is an industrial robot manufactured by Kawasaki. It has a payload of 50kg with a horizontal reach of 2,100mm and a vertical reach of 3,697mm. The unit also has a weight of 555kg and works at a maximum speed of 13,400mm/sand, and can be used with an integrated E42 controller. Additionally, it uses a brushless AC servomotor, a full digital servo system, and an AS-language for programming.

Request for a quote

BERIKA TECHNOLOGY MEDICAL

Turkey

All of its components designed as modular to give the customer a big range of configuration. So electirical and gas components can be added or removed easily according to hospital requirement. No need to stop full system because of technical service. Grounding in all detachable metal parts.

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Chiseling – Square. Practical. Precise. Typical applications for chiseling processes are stake holes on steps for mounting a handrail or inserting fiche hinges in window processing. Whether hard or soft wood, CNC chiseling units help you achieve precise, square cutouts.

Request for a quoteResults for

Verticalization units - Import exportNumber of results

29 ProductsCompany type

Category

- Hydraulic equipment (5)

- Conveyor systems (2)

- Machine tools - metal machining (2)

- Metals - Machines & Equipment (2)

- Automation - systems and equipment (1)

- Coring machinery (1)

- Gases, medical - apparatus and equipment (1)

- Laminating machines and equipment (1)

- Packing and packaging - machinery and equipment (1)

- Painting robots (1)

- Point-of-sale advertising (1)

- Pumps (1)

- Sawing machine tools (1)

- Shop fittings (1)

- Textile coating machines (1)

- Woodworking - machinery and equipment (1)