- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vertical saw

Results for

Vertical saw - Import export

PERGEL METAL

Turkey

A circular saw is a tool used in many industries to reshape or cut some raw materials that have different shapes and sizes. As is known, most saws work by hand power. A circular saw is not a classic type of saw. Since it works with electricity, it is extremely advantageous in all respects. Compared to saws with manual use, there is a different operating system. It is placed on a coffee table and cut vertically. In hand-type saws, the floor is not important. Cutting can be done in any desired place. You can get the circular saw service in the highest quality way from our company.

Request for a quote

PRESSTA EISELE GMBH

Germany

Manual end notching saw to work the ends of aluminium or PVC profiles Use of saw blades Ø 400 mm vertical and horizontal Manual operation with slidable supporting table 2 x 3,0 KW, 400 V, 50 Hz Pneumatic profile clamps horizontal and vertical Material back fence adjustable 30° – 90° read out by scale Vertical saw blade adjustable manually by hand wheel 70° – 90° – 30° Max. Cutting range 135 x 135 mm

Request for a quote

PRESSTA EISELE GMBH

Germany

Variable notching possibilities for mullion and transom combinations, e.g. curtain walls, winter garden, sky lights and special designs Manual adjustment of the horizontal blade max. 20mm to the front to cut slots Notch variation: rectangle, one sided angular, two sided angular, three sided angular Notch dimensions: 185mm horizontal, and 210mm vertical at (90°) Profile dimensions: height maximum 280mm, width maximum 300mm Manual adjustment of saw blade height, positioning via mechanical digital display; electronic display optional Swivelling range vertical saw blade 30°-90°-30° (back/mid/front) positioning via mechanical digital display Swivelling range of both, horizontal and vertical saw blade, 30°-90°-30°, positioning by mechanical digital display Material fence on the table swivelled left / right 30°-90°-30°, positioning by scale Depth stop adjustable via hand wheel and slide, read out by mechanical digital display, manual clamping Semi-automatic precise and safe notching...

Request for a quote

PRESSTA EISELE GMBH

Germany

Variable notching possibilities for mullion and transom combinations, e.g. curtain walls, winter garden, sky lights and special designs. Notch variation: rectangle, one sided angular, two sided angular, 3 sided angular Notch dimensions: 210mm horizontal, 262 mm vertical (90°) Profile dimensions: height maximum 280mm, width maximum 320mm 4-axis adjustment of saw blades positioning via electronic control panel – Notch height – Swivel vertical blade – Swivel vertical and horizontal blade together – Material depth stop Power adjusted notch height – positioning via control panel 0 – 260 mm Power adjusted pivoting range saw blade vertical 90° – 60° + 30° (to front/to back) Power adjusted pivoting range horizontal + vertical saw blade 90° + 45° – 45° Pivoting range material fence on table manually left/right 30° – 90° – 45°, positioning by scale Depth stop power adjusted via control panel. Precise and safe notching due to the work piece is fixed on the table during the cut Hydro...

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

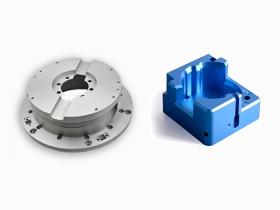

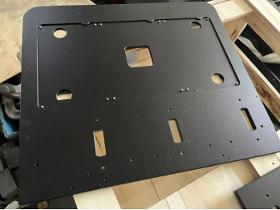

Ming Xiao Mfg custom CNC machined parts by CNC Turning & Milling for worldwide customers. Precision Machining: Our facility is equipped with a wide range of CNC machines including CNC lathes, turning centers with live tools, horizontal and vertical band saws, etc. This helps us to produce precision machined CNC parts. CNC Milling and Turning: We have equipment with 3, 2, 3+2, and 5 machinery axis, which helps us provide end-to-end CNC milling and turning services. Additionally, we can offer sub-operations, such as knurling, milling, drilling, etc. Our Capabilites Maximum Diameter: 600mm Maximun Length: 1200mm Highest Tolerance: ±0.01 (Depending on the parts’ size) ISO 2768 f Available Surface Roughness: Ra 0.4 / Rz3.2 / ▽8 If you are interest in our CNC turning and machining services to produce your aluminum machined parts, welcome send your drawing or samples with detailed requirements to us, we shall reply you in 48 hours and work a more competitive price for you.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg custom CNC machined parts by CNC Turning & Milling for worldwide customers. Precision Machining: Our facility is equipped with a wide range of CNC machines including CNC lathes, turning centers with live tools, horizontal and vertical band saws, etc. This helps us to produce precision machined CNC parts. CNC Milling and Turning: We have equipment with 3, 2, 3+2, and 5 machinery axis, which helps us provide end-to-end CNC milling and turning services. Additionally, we can offer sub-operations, such as knurling, milling, drilling, etc. Our Capabilites Maximum Diameter: 600mm Maximun Length: 1200mm Highest Tolerance: ±0.01 (Depending on the parts’ size) ISO 2768 f Available Surface Roughness: Ra 0.4 / Rz3.2 / ▽8 If you are interest in our CNC turning and machining services to produce your aluminum machined parts, welcome send your drawing or samples with detailed requirements to us, we shall reply you in 48 hours and work a more competitive price for you.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

Semi-automatic machines for single cuts and small seriesWith automatic saw feed and quick-clamping device for the material, the semi-automatic models offer higher cutting output levels and more operating convenience than the manual saw variants. By ensuring fatigue-free working for the operator, they are also suitable for sawing small production runs: Quick-acting pneumatic / hydraulic clamping device Clamping pressure reduction available as option Variable hydro-pneumatically / hydraulically controlled setting of the saw blade feed Easy miter cutting positioning with fixed stop Easy stroke adjustment of the saw unit via 2 clamping levers Well dimensioned worm gear unit with EISELE shock-absorbing feature Quick and easy blade change

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The VMS automatic machines are designed for the ultimate handling simplicity - both for series cuts and in manual operation. The machine operation takes place using a convenient NC control. Where your operations call for frequently changing single cuts, an optional bar start detection system makes for even simpler material handling through fully automatic length positioning without the need for manual intervention. The generously dimensioned casing complies with the latest safety requirements and can be fully opened for improved access. — Material feed with flat guide and ball screw spindle for high-precision positioning — Large-dimensioned cover hoods meet highest safety standards — Easy to operate in automatic and manual operating mode — Can be combined with roller conveyors — 4 speeds as standard for machining almost any steel quality — Both coolant and micro spray system standard

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

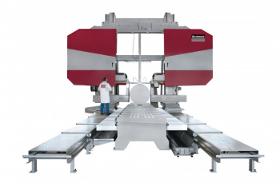

The automatic plate saw VPS60-160A is BEHRINGER's solution when it comes to fully automatic cross-cutting of large plates and blocks. The vertical arrangement of the saw band has clear advantages over the horizontal design, as the engagement length of the saw band is significantly shorter. As a result, the cross cutting plate saw offers significantly higher cutting capacities while at the same time reducing tool costs. Thanks to their robust basic design and high-performance components, the automatic plate saws of the VPS series are designed for demanding applications in the steel trade, industry and metal production. From non-ferrous metals and aluminum to simple work steels and difficult-to-cut materials such as Inconel or titanium. Their modular design allows the cross cutting plate saw to be individually adapted to the customer's application.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

In forging mills, rolling and gravity die-casting foundries, and steel finishing works, these machines provide the ideal answer for dealing with large dimensions. They are perfect for preproduction in tool and mold making factories, helping to save valuable milling time. The material support table is recessed in the foundation. Its low-level transition to the hall floor makes for simpler material handling. The moving saw frame can be positioned by axis control precisely at the point of cutting. Where no sawing is taking place, the table is freely accessible. This also allows space for a second piece of material to be loaded while the saw is cutting. This system helps reduce downtime between cuts and enhances productivity. Benefits of the Gantry Machines - Space-saving installation - Durable material support table - Simple positioning of the saw frame - Optional: blade guide with 90° rotation facility for vertical and horizontal sawing to allow notching of materials

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

Their flexibility and high performance make BEHRINGER tabletop machines the ideal solution for the medium ton range. The table moves the weight BEHRINGER tabletop machines are ideal for use in forges, rolling mills and die casting factories, in steel finishing works and for tool and mold making. Their individually traversable material clamping vices and blade guide arms make these ideal for cutting bulky materials. The low table height makes this type of machine ideally suited for use on normal hall floor level. BEHRINGER tabletop machines are supplied as standard in semi-automatic form. Automation is possible by upgrading with an additional material clamping vice at the end of the table. Positioning takes place on an axiscontrolled basis. Optionally available is 90° rotatable blade guide for vertical and horizontal sawing to allow notching of materials.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

Automatic longitudinal plate cutting or with automatic 90° band rotation for combined longitudinal and cross cutting: the BEHRINGER range of vertical plate saws provides high performance and the ultimate in flexibility. A durable, torsionally rigid welded construction and vibration damped cast components provide the assurance of minimized noise and precise cuts – no matter whether you are processing parts or strips. From NF metals and aluminium through steel to inconel or titanium. LPS vertical bandsaws from BEHRINGER will cut through even the most difficult of materials with the utmost precision – without compromising on speed. This is made possible by a durable, torsionally rigid welded construction in conjunction with vibration damped cast components. The saw feed system is equipped with servo technology together with the sensitive BEHRINGER cutting pressure control system for guaranteed higher cutting outputs and a longer band service life.

Request for a quote

AERO-LIFT VAKUUMTECHNIK GMBH

Germany

Transported materials can be pivoted through 90° with these units. When handling sheet metal, it is not always possible to transport the sheets horizontally. For instance, to feed a vertical saw or remove upright panels standing in a warehouse, it is necessary to have a swivelling range of 90°. With vacuum lifters from AERO-LIFT swivelling is an easy and comfortable task even for a single worker when it comes to large and/ or heavy loads Functionality Swivelling manually for loads up to 150kg With a handle the load can be swivelled manually. Comfortable swivelling with a lifting cylinder Easy to operate with push buttons at the handle. Swivelling continuously without manpower of the user. Sample applications Technical Data to the standard swivelling devices Description Article.No. Carrying capacity Main beam L Cross beam B Suction plate quantity /...

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION ACK 420 S is designed for the strait or angular cutting operations of the large size of profiles made of aluminum and PVC materials by means of Ø 420 mm of saw blade. Two-hand run safety operation Location points at 75°,60°,45°,30°,22.5°,15°,0° both left and right Pivoting range from -75° left to +75° right infinitely adjustable Hydro-pneumatic saw feed Adjustable back fence for most effective use of the saw blade Adjustable saw blade feeding speed Manually opening safety guard Interior LED lighting STANDARD ACCESSORIES • Equipped with saw blade Ø 420 mm • MKN 301 roller conveyor (3 m) • 2 x vertical clamps • Spray saw blade lubrication system (ACK 420S) • Air gun OPTIONAL ACCESSORIES • Additional saw blade Ø 420 mm • 2x horizontal clamp • VCE 1570 Chip vacuum extractor • DKN 300-450-600 conveyor • SKN 300-450-600 conveyor • Laser marker set for 90 ° of cutting operation • Pneumatically working top guard Videolar TECHNICAL SPECIFICATIONS 2.2kW 50/60Hz

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION ACK 420 is designed for the strait or angular cutting operations of the large size of profiles made of PVC and aluminum materials by means of Ø 420 mm of saw blade. HDL 300 It is computerized heavy duty lenghtstop which helps to cut the profiles precisely in the required measurements. ACK 420 General Features Two-hand safety operation Location points at 75°,60°,45°,30°,22.5°,15°,0°, both left and right Pivoting range from -75° left to +75° right infinitely adjustable Hydro-pneumatic saw feed Adjustable back fence for most effective use of the saw blade Adjustable saw blade feeding speed Manually opening safety guard Interior LED lighting STANDARD ACCSSORIES Equipped with saw blade Ø 420 mm Manuel MKN 300 end-stops (3 m) 2 x vertical clamps Spray saw blade lubrication system (ACK 420S) Air gun OPTIONAL ACCESSORIES Laser marker set for 90° of cutting operation Pneumatically working top guard Additional saw blade Ø 420 mm 2x horizontal clamp

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Structurals with light or medium walls • Short chipping materials • Sheet metal on vertical band saw machines

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Vertical saw - Import exportNumber of results

18 ProductsCountries

Company type