- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- ventilation hoods

Results for

Ventilation hoods - Import export

UNNINOX EUROPE B.V.

Netherlands

Brushed structure stainless steel AISI 430 The hood is slant and the filters are installed with an angle of 45 ° Standard with Led Lightning 5W builtin Standard produced with fat drain valve Included Labyrinth filters 400x400mm Included On/Off controller with lightning & gasvalve on/off switch butto

Request for a quote

KITO ARMATUREN GMBH

Germany

For installation into pipes to the protection of vessels and components against deflagration of flammable liquids and gases. Approved for all substances of explosion groups IIA1 to IIA with a maximum experimental safe gap (MESG) > 0.9 mm. Bi-directionally working in pipes, whereby an operating pressure of 1.2 bar abs. and an operating temperature of 60 °C must not be exceeded. The distance between a potential ignition source and the flame arrester must not exceed 50 times the inner pipe diameter. The installation of the Deflagration flame arrester into horizontal and vertical pipes is permissible. When equipped with one or two temperature sensors, the devices are protected under atmospheric conditions against a short time burning by a burning time tBT = 1.0 min. If only one temperature sensor, then it is to be placed on the device side where a burning could be expected.

Request for a quote

KITO ARMATUREN GMBH

Germany

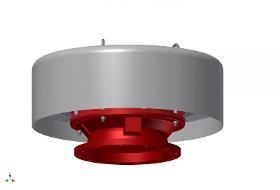

Application as end-of-line armature for venting and breathing of tanks. Tested and approved against atmospheric deflagrations for all materials of the explosion group IIB3 with a maximum experimental safe gap (MESG) ≥ 0.65 mm and a maximum operating temperature of 60 °C. Vertical mounting (for tank roofs) with an integrated elbow as an option.

Request for a quote

KITO ARMATUREN GMBH

Germany

Application as end-of-line armature for venting apertures on tank installations, valve is explosion-proof and endurance-burning proof for certain inflammable liquids. Used mainly as venting and breather device for fixed roof tanks to prevent inadmissible pressure and vacuum and to minimize unwelcome gas losses and inadmissible emissions. Approved for all materials of the explosion group IIA with a maximum experimental safe gap (MESG) > 0.9 and a maximum operating temperature of 60 °C. The housing is mounted perpendicularly on a tank roof. If required by the customer, the valve is equipped with an explosion-proof condensate drain device.

Request for a quote

KITO ARMATUREN GMBH

Germany

As end-of-line armature, for venting apertures on tank installations. Used mainly as venting and breather device for fixed roof tanks. Used to prevent inadmissible pressure and vacuum and to minimize unwelcome gas losses or inadmissible emissions respectively. The housing is mounted perpendicularly on a tank roof. The product vapours can be discharged through a collective line into the atmosphere connected to the line flange on the pressure side.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KITO ARMATUREN GMBH

Germany

As breather/venting safety device incorporating an explosion proof flame arrester element for installation on top of storage tanks, tank access covers or breather pipes. The breather allows the unimpeded flow of gases out to atmosphere and air into the tank/pipe thereby preventing vacuum locks whilst ensuring provision of a permanent and reliable protection against any flashback into the tank/pipe. This device is not permitted to be installed in enclosed areas. Approved for all materials of the explosion group IIB3 with a maximum experi-mental safe gap (MESG) ≥ 0.65 mm and an maximum operating temperature of 60 °C .

Request for a quote

KITO ARMATUREN GMBH

Germany

Proof for products of explosion group IIA with a maximum experimental safe gap (MESG) > 0.9 mm and a maximum operating temperature of 60 °C. Mainly used as equipment of fixed roof tanks for venting and inbreathing to prevent undue pressure resp. vacuum and undesired losses of vaporization, respectively undue emissions. Installation on top of storage vessels. Available with an explosion and endurance burning proofed condensate drain device.

Request for a quote

KITO ARMATUREN GMBH

Germany

Application as installation explosion-proof and endurance burning proof for certain flammable liquids of the explosion group IIA with a maximum experimental safe gap (MESG) > 0.9 mm and a maximum operating temperature of 60 °C. As venting and breather device for fixed roof tanks to prevent inadmissible pressure and vacuum and to minimize gas losses by variable pressure setting of the weight-loaded and/or spring-loaded valve devices. Installation of an explosion-proof condensate drain device is possible.

Request for a quote

KITO ARMATUREN GMBH

Germany

Application as end-of-line armature for venting apertures on tank installations. Tested and approved against atmospheric deflagrations for all materials of the explosion group IIB3 with a maximum experimental safe gap (MESG) ≥ 0.65 mm and a maximum operating temperature of 60 °C. Used mainly as venting and breather device for fixed roof tanks. Used to prevent inadmissible pressure and vacuum and to minimize unwelcome gas losses or inadmissible emissions respectively. The housing is mounted perpendicularly on a tank roof. Available with an explosion and endurance burning proofed condensate drain device.

Request for a quote

KITO ARMATUREN GMBH

Germany

Application as breather/venting safety device incorporating an explosion proof flame arrester element for installation on top of storage tanks, tank access covers or breather pipes. The breather allows the unimpeded flow of gases out to atmosphere and air into the tank/pipe thereby preventing vacuum locks whilst ensuring provision of a permanent and reliable protection against any flashback into the tank/pipe. This device is not permitted to be installed in enclosed areas. Approved for all materials of the explosion group IIB3 with a maximum experimental safe gap (MESG) ≥ 0.65 mm and a maximum operating temperature of 60 °C .

Request for a quote

WWW.MARCHANDISE-PRO.COM

United Kingdom

static hood dynamic hood Decorative professional extractor hood casing Hood Decoration Suspended hood Professional kitchen hood Decorative hood extractor hood Hood Decoration Island hood Professional kitchen hood Decorative hood extractor hood trapeze hood stainless steel hood stainless steel food hood decorative hood professional stainless steel hood motorized hood static hood dynamic hood professional hood with extraction silent professional hood 3m professional extractor hood custom hood professional kitchen hood extractor kitchen hood black island hood matt black island hood restaurant hood sandwich hood professional kitchen hood professional odorless extractor hood extractor hood cap decorative extractor hood decorative stainless steel extractor hood professional extractor hood 150 cm professional extractor hood marseille cheap professional extractor hood Cubic hood

Request for a quote

UNNINOX EUROPE B.V.

Netherlands

Brushed structure stainless steel AISI 430 The hood is slant and the filters are installed with an angle of 45 ° Standard with Led Lightning 5W builtin Standard produced with fat drain valve Included Labyrinth filters 500x500mm Included On/Off controller with lightning & gasvalve on/off switch button

Request for a quote

UNNINOX EUROPE B.V.

Netherlands

With motor Premium workmanship Electronically welded Compact and robust construction LED lighting Quick assembly Easy to clean Single block structure made of stainless steel AISI430 Greasefree labyrinth filter made of stainless steel 18/10 Interior lighting Motor and regülatör Produced according hygiene and safety requirements Meets CE standards Material corresponds to the European Food Product Standards

Request for a quote

KITO ARMATUREN GMBH

Germany

As breather/venting safety device incorporating an explosion proof flame arrester element for installation on top of storage tanks, tank access covers or breather pipes. The breather allows the unimpeded flow of gases out to atmosphere and air into the tank/pipe thereby preventing vacuum locks whilst ensuring provision of a permanent and reliable protection against any flashback into the tank/pipe. This device is not permitted to be installed in enclosed areas. Approved for all materials of the explosion group IIB3 with a maximum experimental safe gap (MESG) ≥ 0.65 and an maximum operating temperature of 60 °C.

Request for a quoteResults for

Ventilation hoods - Import exportNumber of results

15 ProductsCountries

Company type