- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vacuum sintering furnaces

Results for

Vacuum sintering furnaces - Import export

PFEIFFER VACUUM GMBH

Germany

Single-stage rotary vane pumps from Pfeiffer Vacuum have long been some of the most widely used products for processes in the low and medium vacuum range. Their long life and pumping speed, irrespective of the gas used, are the outstanding properties of this pump. Typical applications are found in widely ranging sectors: — Analytics (mass spectrometry, electron microscopy) — Coating technology (surface protection, decorative films, display units, monitor screens) — Vacuum metallurgy (vacuum soldering, vacuum sintering, vacuum alloys, furnace construction) — Leak detection technology (vacuum systems, automotive tanks, airbag cartridges, packaging) — Lighting industry (light bulb manufacture) — Drying industry (vacuum drying, transformer drying)

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

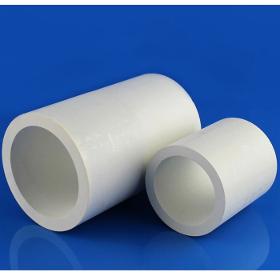

Boron nitride can be long-term used at 1800 degrees under vacuum atmosphere. With gas protection, Boron Nitride can be used at 2100°. Boron Nitride is with high thermal shock resistance, no cracks under extreme cold & high temperature. If you take out Boron Nitride from 1000 degree furnace and colding it within short minutes. It still won't break even repeat this test with 100 times. > Matching materials: BN-99, BN-AL > Advantages: high temperature resistance (2000℃), thermal shock resistance, high electrical breakdown strength (3 -4 times that of alumina), carbon atmosphere corrosion resistance is much stronger than alumina > Used for polysilicon ingot furnace, graphitization heat treatment furnace, vacuum sintering furnace, atmosphere furnace ect. Grades 5 grades of boron nitrides are involved in Boron Nitride product series. * BN99 ● CABN ● ALBN ● ZRBN ● ZABN ● SB

Request for a quote

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

The SSH is a standardized vacuum-pressure sintering furnace for economic production of hardmetal (cemented carbide) parts. It combines the universal application of dewaxing (debinding), vacuum-sintering and isostatic pressing up to 60 bar overpressure in one process. Based on PVA TePla's leadership in production of Sinter HIP furnaces for hardmetal applications, the SSH furnace gives you a most affordable and economic access to this leading technology. Applications: Dewaxing (Debinding), vacuum-sintering, isostatic pressing Customer Benefits: • High product quality by excellent temperature homogeneity • Elaborated safety system for reliable and full-automatic operation • Short dewaxing and cooling times • Short installation and ramp-up times, all pre-tests and qualifications done at PVA site • Proven design and performance • Short delivery time due to pre-production • High cost effectiveness • High energy efficiency • Low gas consumption

Request for a quote

WIGTEC FISCHEREDER KG

Germany

In the WTH 200.2, the following materials can be reliably brazed with active materials in a high vacuum. PCD (polycrystalline diamond) MKD (monocrystalline diamond) CVD diamond (chemical vapour deposition) PCBN (cubic boron nitride) and Hard metals as well Ceramics In the high-vacuum furnace WTH 200.2, our customers manufacture indexable inserts, dressing wheels, rotating tools and turning tools with blades made of natural diamond or MKD for polish turning. The vacuum brazing is flux-free. In the so-called active brazing process, titanium allows wetting of the surfaces. While cemented hard metals can also be inductively brazed, diamonds, CVD and ceramics must be actively brazed in a vacuum. When brazing PCD and PCBN, not only the hard metal substrate but also the PCD or PCBN layers are wetted.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

Our modular control packages are customized to significantly improve your vacuum heat treat operations, meet industry standards requirements and ultimately provide you with precise and reliable process control. We offer compact, fully automatic modules for new installations or retrofits. Each solution consists of a cost-effective module or combination of modules delivered with state-of-the-art equipment and backed by our extensive technological expertise. Vacuum Control Solution is supplied with a PROTHERM programmable controller and optional multiple load thermocouple inputs for soak guarantees. Interfaces to popular vacuum gauges. FEATURES • Full compliance with AMS 2750, CQI-9, NFPA 86-C, NADCAP* • Expanded recipe control including automatic leak test cycles • Guaranteed soaks based on multiple work thermocouples • Recipe control of partial pressure setpoints, guaranteed soak, ramp rates, events and quench gas selection • Built-in uniformity survey capability • Temperature...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Vacuum sintering furnaces - Import exportNumber of results

5 ProductsCountries

Company type